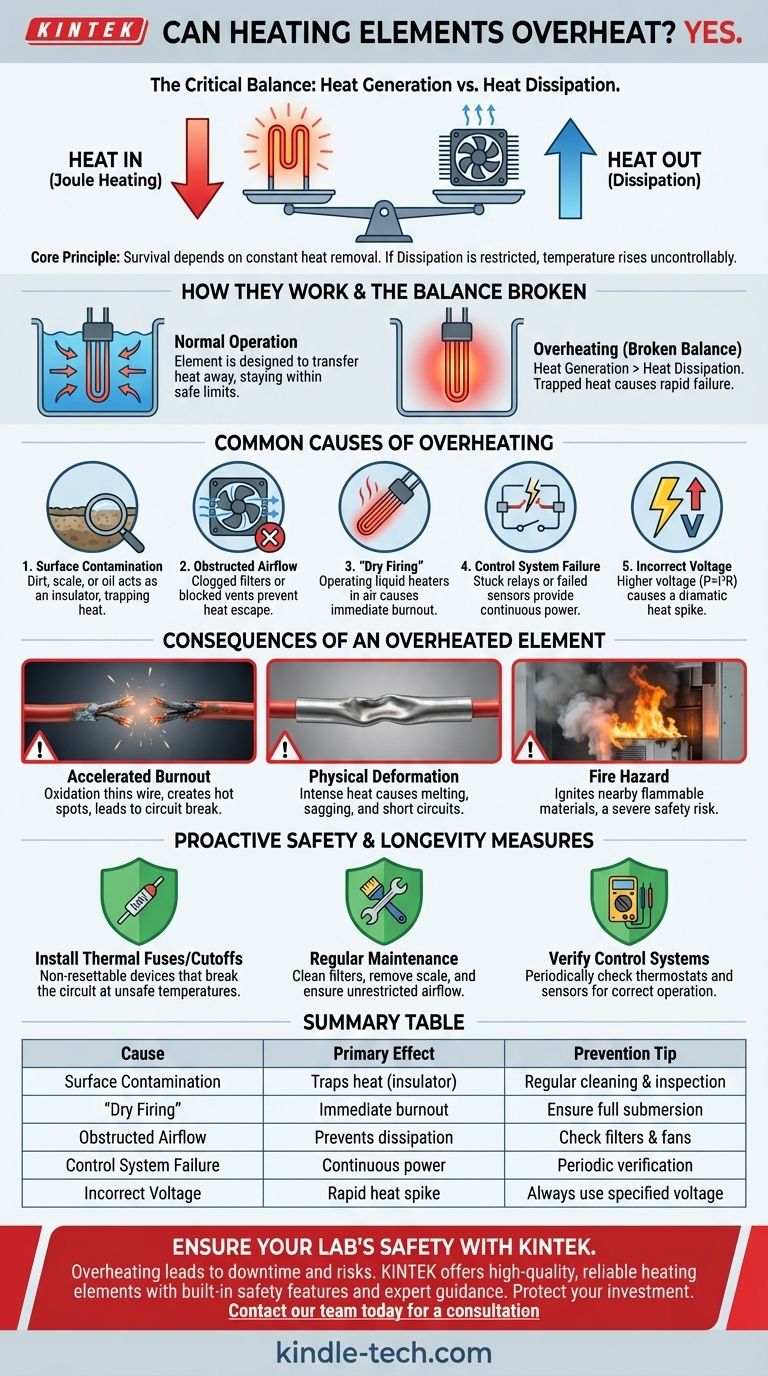

Yes, absolutely. A heating element can and will overheat if the heat it generates is not removed effectively. This is the primary failure mode for these components, leading to accelerated degradation, burnout, and significant safety risks.

The core principle is simple: a heating element's survival depends on a constant balance between heat generation and heat dissipation. When dissipation is restricted for any reason, the internal temperature rises uncontrollably, causing the element to destroy itself.

The Fundamental Principle: Heat In vs. Heat Out

How Heating Elements Work

All conventional heating elements operate on the principle of Joule heating. When an electric current flows through a material with high electrical resistance, such as Nichrome wire, the electrical energy is converted directly into heat energy.

The element is engineered to operate at a specific temperature that allows it to effectively heat its surrounding medium—be it air, water, or a solid surface—without degrading.

The Critical Role of Heat Dissipation

The element is not designed to simply get hot; it's designed to transfer that heat away into its intended environment. This continuous transfer is what keeps the element's internal temperature within its safe operating limits.

For example, an immersion heater is designed for the high thermal conductivity of water to constantly pull heat away. A forced-air heater relies on a fan to move cooler air over its fins, carrying the heat away.

When the Balance is Broken

Overheating is the direct result of this balance being broken. If the rate of heat generation exceeds the rate of heat dissipation, the element’s temperature will climb rapidly.

This trapped heat quickly pushes the resistive wire and its protective sheath beyond their material limits, initiating a rapid failure sequence.

Common Causes of Overheating

Contamination on the Element Surface

One of the most frequent causes of failure is the buildup of foreign material on the element's surface. Dust, oil, mineral scale (in water), or manufacturing residue acts as an insulator.

This insulating layer traps heat, preventing it from escaping. The internal temperature of the element skyrockets, even though the surrounding environment may still be cool.

Obstructed Airflow or Poor Circulation

In air heaters, anything that blocks or slows the flow of air over the element is a direct cause of overheating. A clogged air filter, a failed fan, or a blocked vent prevents the heat from being carried away.

Think of it like a hairdryer with its air intake covered—the heating coil will glow red hot and burn out almost instantly.

"Dry Firing" Immersion Heaters

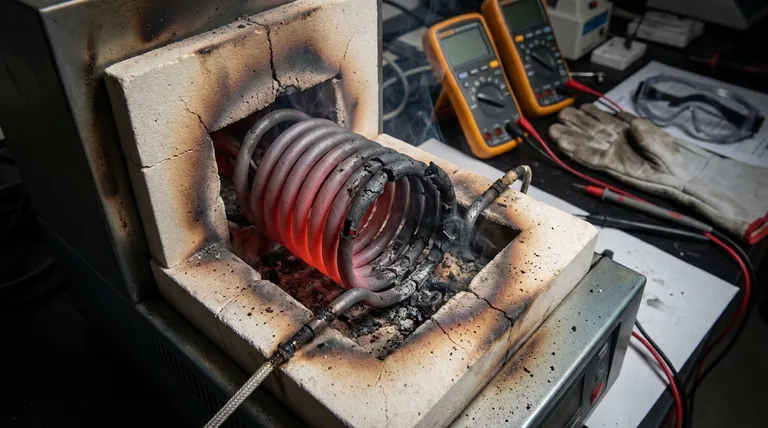

A critical failure mode occurs when a heater designed for liquids is operated in open air. This is known as dry firing.

Air is a very poor conductor of heat compared to water. When an immersion heater is turned on without being submerged, the heat cannot escape quickly enough, causing a catastrophic and often immediate burnout.

Failure of Control Systems

Heating elements are governed by control systems like thermostats, relays, and sensors. If a relay becomes stuck in the "on" position or a thermostat fails, the element will receive continuous power.

Without the control system cycling the power off, the element will continue to generate heat indefinitely, inevitably leading to overheating.

Incorrect Voltage

Applying a voltage higher than the element's design specification forces excessive current through the resistive wire. Since heat generation is proportional to the square of the current (P = I²R), even a small increase in voltage can cause a dramatic and damaging spike in heat output.

The Consequences of an Overheated Element

Accelerated Oxidation and Burnout

The resistive wire inside most elements (like Nichrome) is protected by a thin, stable layer of oxide. Extreme temperatures cause this layer to break down and reform rapidly, consuming the wire material.

This process, known as accelerated oxidation, thins the wire, increases its resistance in spots, and creates hot spots that quickly lead to a complete break in the circuit—what we call burnout.

Physical Deformation

The intense heat can cause the element and its metal sheath to warp, sag, or even melt. This can cause it to make contact with other components, creating short circuits or further damage.

Fire Hazard

This is the most severe risk. An overheating element can easily ignite nearby flammable materials, including built-up dust and debris, wire insulation, or plastic components within an appliance. The majority of safety features in heating appliances are designed specifically to prevent this outcome.

A Proactive Approach to Safety and Longevity

The Role of Thermal Fuses and Cutoffs

Most appliances include a thermal fuse or cutoff switch. These are crucial, non-resettable safety devices. They are designed to physically break the electrical circuit if they detect a temperature that exceeds the safe maximum, permanently disabling the element to prevent a fire.

Proper Installation and Maintenance

Proper installation is the first line of defense. This means ensuring the element has unrestricted airflow, is fully submerged if it's an immersion type, and is connected to the correct voltage.

Regular maintenance, such as cleaning filters and removing any scale or dust buildup from the element itself, is critical for ensuring effective heat dissipation throughout its life.

Verify Control System Function

Periodically checking that thermostats and control circuits are operating correctly ensures the element is only energized when needed. A failed controller is a silent threat that can lead directly to an overheating event.

Making the Right Choice for Your Goal

- If your primary focus is safety: Ensure that all protective devices, especially thermal fuses and cutoffs, are in place and are the correct rating for the application. Never bypass them.

- If your primary focus is equipment longevity: Prioritize a schedule of regular cleaning and inspection to prevent contaminant buildup and ensure proper heat transfer.

- If your primary focus is reliable operation: Always verify that the element is supplied with the correct voltage and that all control systems are calibrated and functioning as designed.

Understanding how a heating element lives and dies by its ability to shed heat is the key to preventing failure and ensuring safe operation.

Summary Table:

| Cause of Overheating | Primary Effect | Prevention Tip |

|---|---|---|

| Surface Contamination (dust, scale) | Acts as insulator, traps heat | Regular cleaning and inspection |

| Dry Firing (immersion heaters) | Catastrophic, immediate burnout | Ensure full submersion before powering on |

| Obstructed Airflow | Prevents heat dissipation, creates hot spots | Check and clean filters, verify fan operation |

| Control System Failure (e.g., stuck relay) | Continuous power, unchecked temperature rise | Periodic verification of thermostats and sensors |

| Incorrect Voltage Supply | Excessive current, rapid heat spike | Always use specified voltage |

Ensure your lab's heating equipment operates safely and efficiently.

Overheating elements lead to costly downtime, unsafe conditions, and compromised results. KINTEK specializes in high-quality lab equipment and consumables, including reliable heating elements designed for precise control and built-in safety features. Our experts can help you select the right equipment for your specific application and provide guidance on proper maintenance to extend its lifespan.

Protect your investment and your lab. Contact our team today for a consultation on your laboratory heating needs.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is a graphite heater? Achieve Superior Temperature Uniformity and Stability

- Are heating elements safe? Ensuring Reliable and Secure Thermal Processing

- Why must YAG:Ce powder from aerosol pyrolysis undergo thermal annealing? Unlock Peak Phosphor Performance

- Why do heating elements break? Understand the root causes and extend their lifespan.

- What are the technical advantages of using graphite rods? Boost Precision in 1200°C High-Temperature Operations

- What is the best heating element for a furnace? A Guide to Selecting the Right Material for Your Temperature Needs

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is the core function of resistance wire heating elements in a magnesium alloy waste recovery furnace? Expert Guide