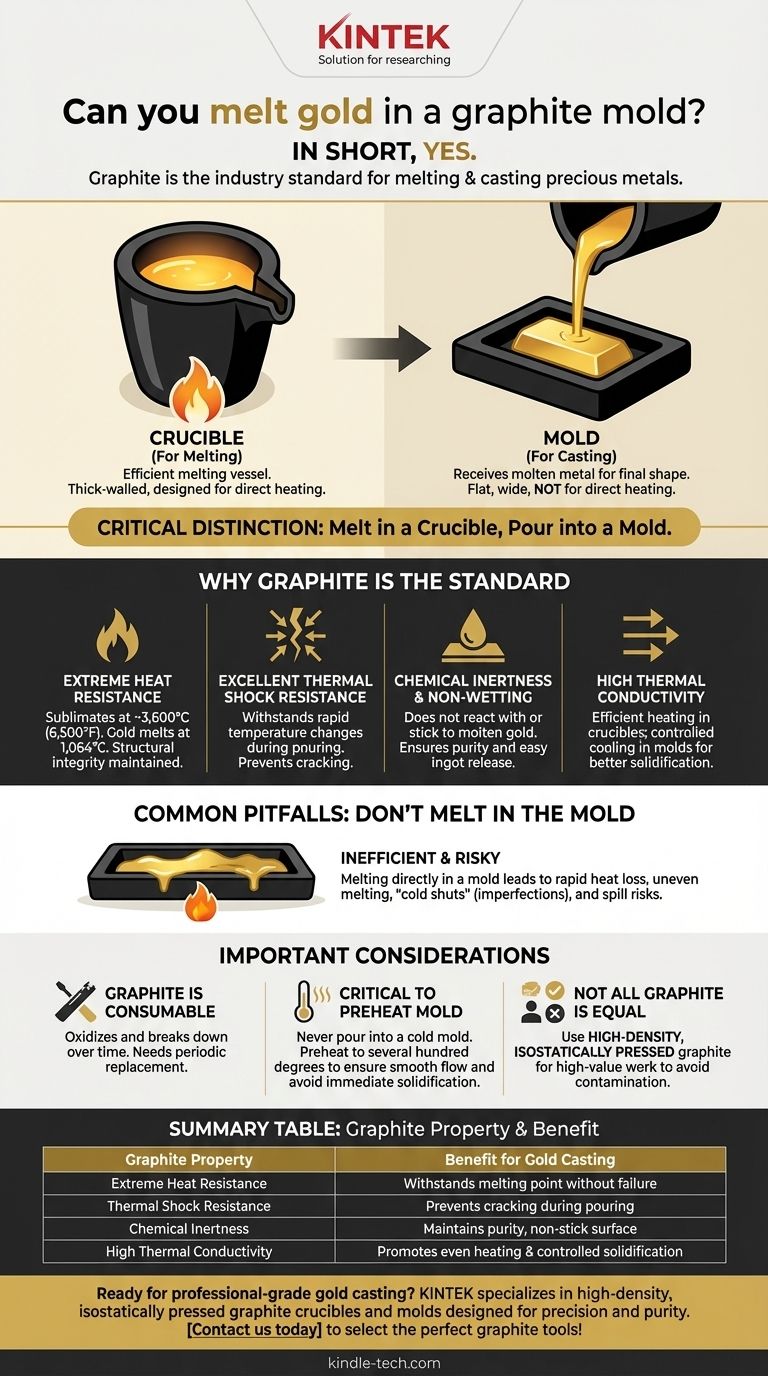

In short, yes. Not only can you use a graphite mold for molten gold, but graphite is the universally accepted industry standard for this task. Its unique combination of extreme heat resistance and non-reactive properties makes it the ideal material for both melting crucibles and casting molds used with precious metals.

The critical distinction is not if you should use graphite, but how. Professionals melt gold in a graphite crucible and then pour it into a graphite mold. Confusing these two roles is a common mistake that leads to poor results and unnecessary risk.

Why Graphite is the Standard for Gold Casting

Graphite's dominance in this field isn't accidental; it's due to a specific set of material properties that make it uniquely suited for handling molten metal.

Extreme Heat Resistance

Graphite does not melt. Instead, it sublimates (turns from a solid directly to a gas) at an incredibly high temperature of around 3,600°C (6,500°F). Gold melts at a much lower 1,064°C (1,948°F), meaning the graphite container's structural integrity is never at risk.

Excellent Thermal Shock Resistance

Graphite can withstand rapid and extreme changes in temperature without cracking or failing. This is essential when you pour molten gold into a mold, creating a massive and sudden thermal gradient.

Chemical Inertness and Non-Wetting Properties

This is perhaps the most important characteristic. Molten gold does not chemically react with or "wet" (stick to) the surface of high-quality graphite. This non-wetting property ensures two things: the purity of your gold is maintained, and the finished ingot releases easily from the mold without damage.

High Thermal Conductivity

Graphite conducts heat very well. In a crucible, this allows for efficient and uniform heating of the gold. In a mold, it helps draw heat away from the molten gold in a controlled manner, promoting an even solidification process for a better final product.

The Correct Process: Crucible vs. Mold

Understanding the difference between these two tools is the key to achieving a professional-quality cast. They are not interchangeable.

The Role of the Crucible

A crucible is the vessel in which you actually melt the gold. It's typically a thick-walled, cup-shaped container designed to be heated directly by a furnace or a torch. Its shape contains the melt efficiently and provides a spout for a controlled, clean pour.

The Role of the Mold

A mold (or ingot mold) is the vessel that gives the molten gold its final shape. It is designed to receive the liquid metal, not to be heated directly to melting temperatures. Molds are often flatter and wider than crucibles.

Why You Shouldn't Melt Directly in a Mold

While technically possible with a small amount of gold, melting directly in an open ingot mold is inefficient and risky. The shallow shape exposes a large surface area, leading to rapid heat loss and making it difficult to get an even melt. This often results in "cold shuts"—imperfections where the metal solidifies before fusing properly—and increases the chance of dangerous spills.

Understanding the Trade-offs and Common Pitfalls

While graphite is the best material for the job, it requires proper handling and awareness of its limitations.

Graphite is a Consumable

Graphite oxidizes and slowly breaks down when exposed to high heat and oxygen. With each use, a microscopic layer is worn away. Your crucibles and molds will not last forever and should be considered consumable items that need periodic replacement.

The Critical Need to Preheat Your Mold

Never pour molten gold into a cold mold. The extreme temperature difference can cause the gold to solidify instantly on the surface, resulting in a poor finish and an incomplete cast. Always preheat your graphite mold to several hundred degrees to reduce thermal shock and ensure the metal flows freely.

Not All Graphite is Created Equal

Graphite comes in different grades of density and purity. For high-value work, use high-density, isostatically pressed graphite. Cheaper, more porous graphite can potentially trap small amounts of metal or introduce impurities into your melt.

Safety is Paramount

Working with molten metal is inherently dangerous. Always use proper personal protective equipment (PPE), including a full face shield, heat-resistant gloves, and a leather or fire-retardant apron. Ensure your workspace is well-ventilated and free of flammable materials.

Making the Right Choice for Your Project

To ensure a successful and safe outcome, tailor your approach to your specific objective.

- If your primary focus is creating clean, well-formed ingots: Always use a separate graphite crucible for melting and a preheated graphite mold for casting.

- If your primary focus is maximizing the lifespan of your tools: Avoid excessive or prolonged heating, especially on the mold, and handle the graphite carefully to prevent chips or cracks.

- If your primary focus is ensuring the highest purity: Invest in high-density graphite tools from a reputable supplier and dedicate specific crucibles to specific metals to prevent cross-contamination.

By understanding the distinct roles of the crucible and the mold, you move from simple melting to precise and professional casting.

Summary Table:

| Graphite Property | Benefit for Gold Casting |

|---|---|

| Extreme Heat Resistance | Withstands gold's melting point (1,064°C) without structural failure |

| Thermal Shock Resistance | Prevents cracking during rapid temperature changes (e.g., pouring) |

| Chemical Inertness | Maintains gold purity; non-stick surface ensures easy release |

| High Thermal Conductivity | Promotes even heating in crucibles and controlled solidification in molds |

Ready to achieve professional-grade gold casting?

KINTEK specializes in high-density, isostatically pressed graphite crucibles and molds designed for precision and purity. Our lab equipment ensures your precious metals are handled safely and efficiently, minimizing contamination and maximizing tool lifespan.

Contact us today to discuss your specific needs and let our experts help you select the perfect graphite tools for your laboratory!

Visual Guide

Related Products

- Special Shape Press Mold for Lab

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Round Bidirectional Press Mold for Lab

People Also Ask

- Why are high-strength graphite molds essential for vacuum hot pressing? Optimize Your Diamond/Copper Composites

- What functions do high-purity graphite molds serve for IZO targets? Ensure Density and Prevent Sintering Cracks

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?

- What technical characteristics are required for specialty pressure molds used in the compaction of Li10GeP2S12? Expert Tips

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity