Yes, you can reheat a brazed joint, but the consequences and feasibility depend entirely on your objective, the temperatures involved, and the specific brazing alloy used. Whether you are performing a repair, disassembling a component, or conducting a post-braze heat treatment, reheating is a common but technically sensitive operation that requires precise control.

Reheating a brazed joint is a standard procedure for repair and disassembly. However, the key to success is understanding that each heat cycle alters the joint's fundamental metallurgy. Uncontrolled or repeated heating can degrade the joint's integrity by promoting the growth of brittle compounds at the interface of the base and filler metals.

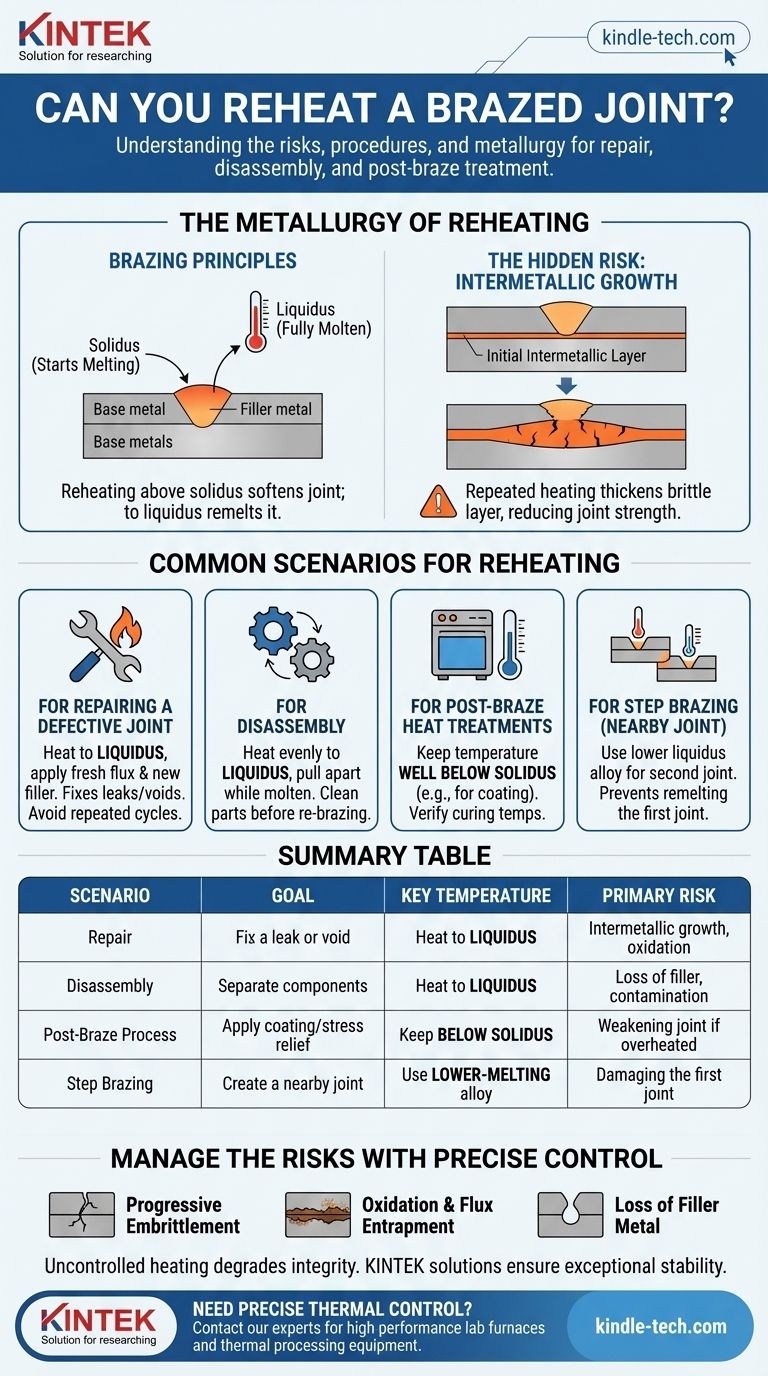

The Metallurgy of Reheating

To make an informed decision, you must first understand what happens within the joint at elevated temperatures.

Brazing Principles: Solidus and Liquidus

A brazed joint is formed when a filler metal is heated above its melting point and drawn into a gap between base metals by capillary action.

Every brazing alloy has two critical temperatures: the solidus, where it begins to melt, and the liquidus, where it becomes fully liquid. The range between them is the "pasty" or melting range.

Reheating a joint above its solidus temperature will cause it to soften and lose strength. Reheating it to its liquidus temperature will allow the filler metal to flow again, essentially re-melting the joint.

The Hidden Risk: Intermetallic Growth

During the initial brazing process, a very thin layer of a new, mixed-metal compound, called an intermetallic, forms where the filler and base metals meet. This layer is essential for a strong bond.

However, this intermetallic layer is harder and more brittle than either the filler or base metals. Each time the joint is reheated for a prolonged period, this layer can grow thicker, making the entire joint progressively more brittle and susceptible to cracking under stress or vibration.

Common Scenarios for Reheating a Joint

Your reason for reheating the joint dictates the correct procedure and level of risk.

For Repairing a Defective Joint

This is the most common reason for reheating. If a joint has a leak or a void, it can often be repaired by reheating it to the filler's liquidus temperature to reflow the alloy.

For a successful repair, you must apply fresh flux to clean the joint and displace oxides. It is also common to add a small amount of new filler metal to ensure the gap is completely filled. This is often a viable one-time solution.

For Disassembly of Components

To take a brazed assembly apart, you must heat the entire joint area evenly to the filler metal's liquidus temperature.

Once the filler is fully molten, the components can be pulled apart. Be aware that the parts will be coated in the old filler metal, which must be mechanically or chemically cleaned before they can be re-brazed.

For Post-Braze Heat Treatments

Processes like powder coating or stress-relieving require the entire assembly to be heated in an oven. This is perfectly safe as long as the oven temperature remains well below the solidus temperature of the brazing filler metal.

Always verify the curing temperature of the coating and compare it to the solidus point specified by the filler metal manufacturer.

For Creating a Nearby Joint (Step Brazing)

When you must braze another joint in close proximity to an existing one, the best practice is step brazing.

This technique involves using a high-temperature brazing alloy for the first joint, followed by a different alloy with a lower liquidus temperature for the second joint. This allows you to form the second joint without bringing the first one anywhere near its melting point.

Understanding the Trade-offs and Risks

While reheating is possible, it is not without risks that you must manage carefully.

Progressive Embrittlement

As noted, the primary metallurgical risk is the growth of the intermetallic layer. While a single, quick repair cycle may have a minimal effect, multiple reheating cycles will almost certainly degrade the joint's ductility and fatigue life.

Oxidation and Flux Entrapment

Reheating a joint without adequate flux or a protective atmosphere will cause oxides to form on the surface of the filler and base metals. These oxides prevent the filler from re-bonding properly.

Applying too much heat too quickly can also "burn" the flux, rendering it inactive and potentially trapping corrosive residues within the joint.

Loss of Filler Metal

When you bring a joint back to its liquidus temperature, the filler metal will flow. If the part is oriented incorrectly or the heating is uneven, the alloy can run out of the joint, creating voids and weakening the connection.

Making the Right Choice for Your Goal

Your approach should be dictated by your specific engineering or maintenance goal.

- If your primary focus is repair: Reheat the joint to liquidus, apply fresh flux, and add a small amount of new filler, but avoid repeated repair cycles on the same joint.

- If your primary focus is disassembly: Heat the joint area evenly to the filler's liquidus temperature and separate the components while the alloy is fully molten.

- If you are performing a post-braze process (like coating): Ensure the process temperature always remains safely below the brazing alloy's solidus temperature.

- If you are designing a multi-joint assembly: Proactively design for success by using the step brazing technique with alloys of sequentially lower melting points.

By understanding these core principles, you can manage the reheating process to achieve your objective without compromising the long-term integrity of your assembly.

Summary Table:

| Scenario | Goal | Key Temperature | Primary Risk |

|---|---|---|---|

| Repair | Fix a leak or void | Heat to filler metal's liquidus | Intermetallic growth, oxidation |

| Disassembly | Separate components | Heat to filler metal's liquidus | Loss of filler metal, part contamination |

| Post-Braze Process | Apply coating or stress relief | Keep below filler metal's solidus | Weakening the joint if overheated |

| Step Brazing | Create a nearby joint | Use a lower-melting-point alloy | Damaging the first joint |

Need precise thermal control for your brazing and post-braze processes?

At KINTEK, we specialize in high-performance lab furnaces and thermal processing equipment that deliver the accurate, uniform heating required for successful brazing, repair, and heat treatment. Our solutions help you avoid the risks of intermetallic growth and oxidation by providing exceptional temperature stability and control.

Whether you are in R&D, manufacturing, or maintenance, KINTEK's equipment is designed to meet the stringent demands of metallurgical work. Contact our thermal experts today to find the perfect furnace for your specific brazing applications and ensure the integrity of your critical assemblies.

Visual Guide

Related Products

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- At what temperature does graphite melt? Understanding Its Extreme Phase Change

- Why is graphite so hard to melt? The Secret Lies in Its Atomic Structure

- What are the physical and chemical properties of graphite? A Unique Material for Extreme Applications

- How does an induction graphitization furnace facilitate the transformation of unburned carbon into synthetic graphite?