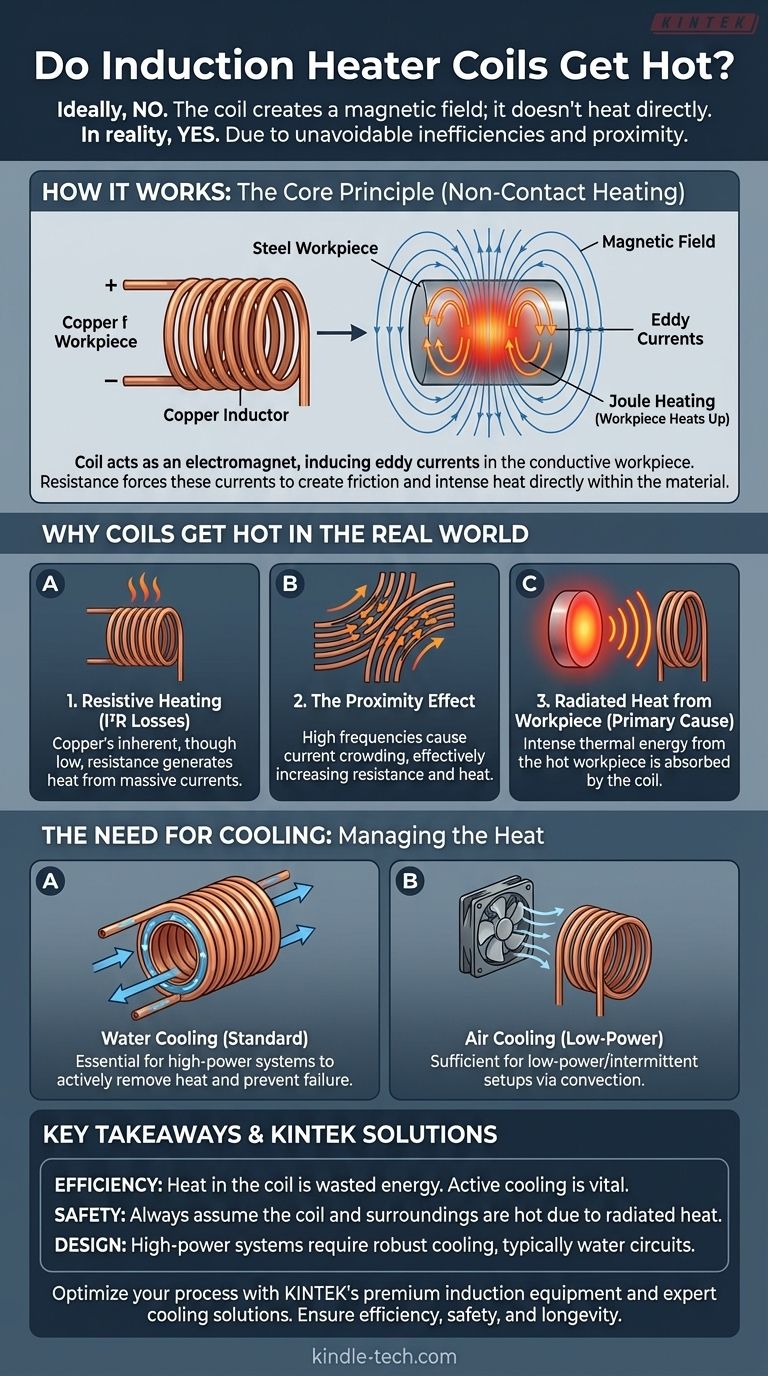

In an ideal induction heating system, the coil itself does not get hot. Its function is to create a powerful, rapidly changing magnetic field, not to act as a direct heating element like the burner on an electric stove. However, in any real-world application, the induction coil will heat up due to electrical inefficiencies and, more significantly, proximity to the object being heated.

The core principle to understand is that induction heating warms the workpiece directly, not the coil. The heat you feel on the coil is a secondary, unavoidable side effect caused by its own electrical resistance and heat radiating back from the extremely hot workpiece.

The Core Principle: How Induction Heating Works

Induction heating is a non-contact process. The coil's role is not to generate thermal energy itself, but to transmit energy wirelessly to the target material through a magnetic field.

The Role of the Induction Coil

An induction coil is essentially a powerful electromagnet. When a high-frequency alternating current (AC) is passed through it, the coil generates a dynamic and intense magnetic field in the space within and around it.

Generating an Eddy Current

When a conductive material, such as a piece of steel (the workpiece), is placed inside this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents.

Why the Workpiece Heats Up

The workpiece has natural electrical resistance. As these powerful eddy currents are forced to flow through the material's resistance, they generate tremendous friction and heat. This phenomenon, called Joule heating, is what causes the workpiece to become hot, often glowing red-hot in seconds.

Why Coils Get Hot in the Real World

While the coil's primary job is magnetic, several factors cause it to heat up during operation. In high-power systems, this heat is significant and must be managed.

Resistive Heating (I²R Losses)

The coil is typically made of copper, which has very low but non-zero electrical resistance. The massive currents required to generate a strong magnetic field will cause the coil itself to heat up due to its own internal resistance. This is a fundamental source of energy loss.

The Proximity Effect

In a coil, the conductors are wound closely together. At high frequencies, this proximity forces the current to flow in concentrated areas of the copper wire rather than spreading out evenly. This "crowding" effect effectively increases the wire's resistance, generating even more waste heat.

Radiated Heat from the Workpiece

This is often the most significant source of heat in the coil. The workpiece can reach temperatures of hundreds or even thousands of degrees. It radiates this intense thermal energy in all directions, and the nearby coil absorbs a substantial amount, causing its temperature to rise dramatically.

Understanding the Trade-offs: The Need for Cooling

Because of these combined heating effects, managing the coil's temperature is a critical design consideration. An overheated coil can fail catastrophically.

Water Cooling is Standard

For nearly all industrial or high-power induction heaters, the coil is constructed from hollow copper tubing. Cool water is continuously pumped through the inside of the coil to actively remove the heat generated by both electrical resistance and radiation from the workpiece. This cooling is not optional; it is essential for the system's survival.

Air Cooling for Low-Power Systems

In very low-power or intermittent-use applications (like some hobbyist setups), active water cooling might not be necessary. Natural air convection or a small fan may provide sufficient cooling to keep the coil within a safe operating temperature.

Making the Right Choice for Your Goal

Understanding why the coil heats up is key to applying induction technology effectively and safely.

- If your primary focus is efficiency: Remember that any heat in the coil is wasted energy; active cooling is necessary to maintain the coil's integrity and transfer power effectively to the workpiece.

- If your primary focus is safety: Always assume the coil and its immediate surroundings are hot, primarily from the intense heat radiating off the workpiece.

- If your primary focus is system design: Incorporating an active cooling circuit (usually water) is a fundamental requirement for any system intended for high power or continuous use.

By distinguishing between the primary heating of the workpiece and the secondary heating of the coil, you can properly design, operate, and troubleshoot any induction system.

Summary Table:

| Cause of Coil Heating | Description | Impact |

|---|---|---|

| Resistive Heating (I²R Losses) | Copper coil's internal resistance generates heat from high current. | Minor source of energy loss; contributes to coil temperature rise. |

| Proximity Effect | High-frequency current crowds in the wire, increasing effective resistance. | Increases resistive heating, requiring more robust cooling. |

| Radiated Heat from Workpiece | Intense heat from the hot workpiece radiates onto the nearby coil. | Often the primary source of heat; necessitates active cooling. |

| Cooling Method | Application | Purpose |

| Water Cooling | Industrial/High-power systems | Actively removes heat to prevent coil failure; essential for efficiency. |

| Air Cooling | Low-power/Hobbyist systems | Manages lower heat levels via convection or fans for intermittent use. |

Optimize Your Induction Heating Process with KINTEK

Understanding the dynamics of coil heating is crucial for achieving maximum efficiency, safety, and equipment longevity in your laboratory or production line. Whether you are designing a new system or troubleshooting an existing one, managing coil temperature is non-negotiable.

KINTEK specializes in premium lab equipment and consumables, providing robust solutions for all your induction heating needs. Our expertise ensures you get the right equipment with the appropriate cooling systems to protect your investment and enhance your results.

Let us help you:

- Select the ideal induction heating system for your specific application and power requirements.

- Implement effective cooling solutions to maintain peak performance and prevent downtime.

- Access high-quality consumables and expert support to keep your operations running smoothly.

Don't let coil overheating compromise your work. Contact our experts today to discuss your project and discover how KINTEK's solutions can bring precision and reliability to your lab.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Automatic Laboratory Heat Press Machine

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What are the different types of sieving machines? Choose the Right Motion for Your Material