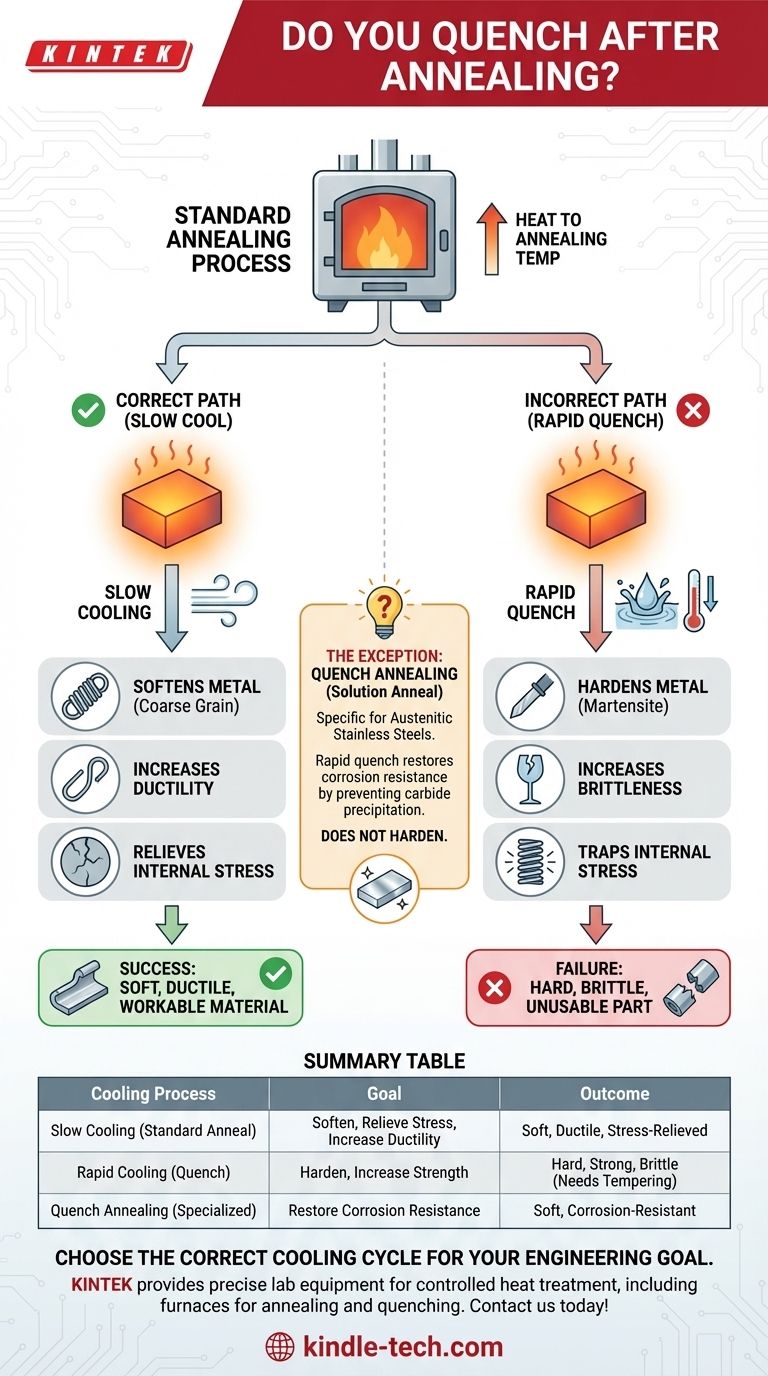

In almost all cases, you do not quench after annealing. Standard annealing, by definition, requires a slow and controlled cooling process to achieve its intended results. Quenching, which is rapid cooling, would fundamentally counteract the entire purpose of the heat treatment, resulting in a material with properties opposite to those desired from an anneal.

The defining characteristic of an annealing process is slow cooling, which softens metal, increases its ductility, and relieves internal stresses. Quenching is a hardening process defined by rapid cooling. Mistaking one for the other will lead to unintended and often detrimental changes in your material's properties.

The Fundamental Goal of Annealing

What Annealing Achieves

Annealing is a heat treatment process used to alter a material's microstructure to achieve specific desirable properties.

Its primary goals are to soften the metal, make it more ductile (easier to form or machine), and relieve internal stresses introduced during manufacturing processes like cold working or welding.

The Critical Role of Slow Cooling

To achieve this softened state, the material is heated to a specific temperature (e.g., above the Ac3 for a full anneal of steel) and then cooled very slowly.

This slow cooling allows the crystalline structure, or grains, of the metal to recrystallize and grow into a more uniform, coarse, and stress-free state. This new structure is what gives the metal its softness and ductility.

Why Quenching Contradicts Standard Annealing

Quenching's Purpose: Hardening

Quenching is the process of cooling a metal rapidly, typically by immersing it in a fluid like water, oil, or a polymer solution.

Its purpose is the opposite of annealing: to "lock in" a hard, brittle microstructure. In steels, this process is used to form martensite, which is responsible for the high hardness of tools and structural components.

Conflicting Microstructural Goals

If you were to quench a part after holding it at its annealing temperature, you would trap the material in a hardened, high-stress state.

This would completely negate the stress relief and softening that the annealing process was meant to achieve, resulting in a failed heat treatment.

The Exception: Understanding "Quench Annealing"

A Specific Process for Specific Alloys

While it sounds like a contradiction, a distinct process called quench annealing (also known as solution annealing) does exist. This is not a standard annealing process and is applied to very specific alloys.

It is most commonly associated with austenitic stainless steels (like the 300 series) and some other non-ferrous alloys.

The Case of Austenitic Stainless Steels

When austenitic stainless steels are heated or welded, they can form chromium carbides at the grain boundaries. This depletes the surrounding area of chromium, compromising the material's corrosion resistance.

Solution annealing involves heating the steel to a high temperature (e.g., 1050°C / 1922°F) to dissolve these harmful carbides back into the material's solid solution. A rapid quench is then used to cool the material so quickly that the carbides do not have time to reform.

The Goal is Corrosion Resistance, Not Hardening

Crucially, the goal of a quench anneal is not to harden the steel. Austenitic stainless steels are non-hardenable by heat treatment; they do not form martensite when quenched.

The sole purpose of the quench is to preserve the material's corrosion resistance by keeping chromium evenly distributed throughout the structure. The resulting material is actually in its softest possible state.

Understanding the Trade-offs of Cooling Rate

Slow Cooling (Standard Annealing)

- Outcome: A soft, ductile, and stress-relieved material with a coarse grain structure.

- Best for: Preparing a material for extensive forming, deep drawing, or difficult machining operations.

Rapid Cooling (Quenching)

- Outcome: A hard, strong, but more brittle material with a fine, highly stressed microstructure.

- Best for: Creating components that require high strength and wear resistance, like cutting tools, gears, or springs (often followed by a tempering process).

The Consequence of Error

Applying the wrong cooling rate is a critical failure. Quenching a part that should be annealed will result in a component that is hard, brittle, and filled with internal stress—entirely failing the original objective and likely rendering the part useless for its intended application.

Making the Right Choice for Your Goal

To ensure you achieve the correct material properties, you must match the cooling process to your engineering requirement.

- If your primary focus is to soften metal, relieve stress, or increase ductility: You must use a slow cool, which is the defining characteristic of a standard anneal.

- If your primary focus is to harden steel for strength and wear resistance: You need to quench the material from its high-temperature (austenitic) state.

- If your primary focus is to restore corrosion resistance in an austenitic stainless steel: You must use a quench anneal (solution anneal) to prevent harmful carbide precipitation.

Understanding that the cooling rate dictates the final properties of the metal empowers you to select the precise heat treatment for your engineering goal.

Summary Table:

| Cooling Process | Goal | Outcome |

|---|---|---|

| Slow Cooling (Standard Anneal) | Soften metal, relieve stress, increase ductility | Soft, ductile, stress-relieved material |

| Rapid Cooling (Quench) | Harden steel for strength and wear resistance | Hard, strong, but brittle material (requires tempering) |

| Quench Annealing (Specialized) | Restore corrosion resistance in austenitic stainless steels | Soft, corrosion-resistant material |

Ensure your heat treatment process is a success.

Choosing the correct cooling cycle is critical to achieving the desired material properties in your components. Mistakes can lead to failed parts, wasted time, and increased costs.

KINTEK specializes in providing the precise lab equipment and consumables needed for controlled heat treatment processes, including furnaces designed for both annealing and quenching applications. Our expertise supports laboratories in achieving accurate and repeatable results.

Contact us today to discuss your specific heat treatment requirements and how our solutions can enhance your lab's capabilities. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength