Yes, the casting process fundamentally alters a material's properties. While the chemical composition of the alloy remains the same, the method of solidifying molten metal into a mold creates a unique internal architecture, or microstructure. This microstructure—the size, shape, and arrangement of the material's internal crystals—is what ultimately dictates its mechanical performance, including its strength, ductility, and fatigue resistance.

The core takeaway is that a material's properties are determined not just by its chemical formula, but by its manufacturing history. Casting creates a distinct microstructure that is fundamentally different from a forged or machined part, leading to a different set of engineering trade-offs.

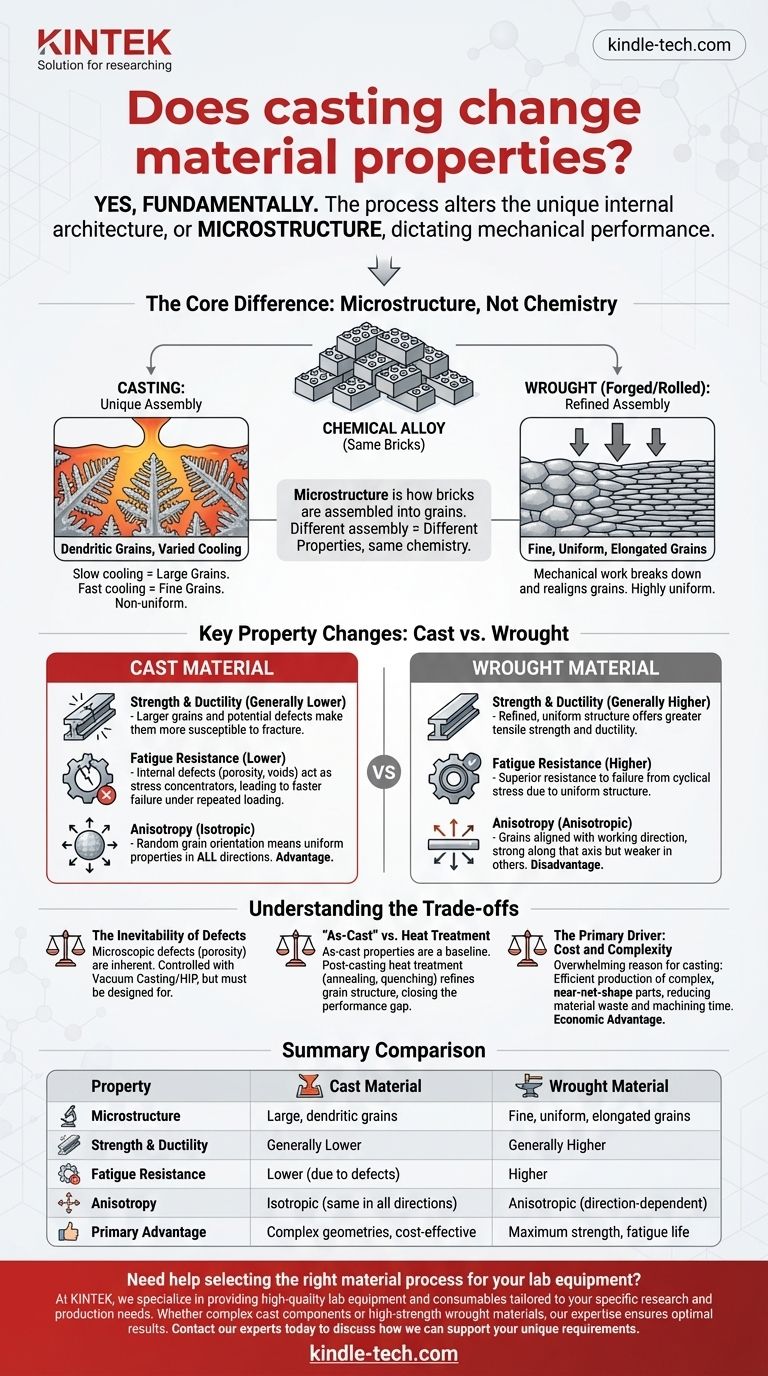

The Core Difference: Microstructure, Not Chemistry

The distinction between a cast part and a wrought (forged, rolled, or extruded) part comes down to their internal grain structure. This is the single most important concept to grasp.

What is Microstructure?

Think of a material's atoms as individual Lego bricks. The chemical alloy is the collection of bricks you have. The microstructure is how those bricks are assembled into larger, crystalline structures called grains. A different assembly results in a different final object, even with the exact same bricks.

How Casting Creates Its Microstructure

During casting, molten metal cools and solidifies. This process is not uniform. Crystals, known as grains, begin to form and grow, often in a tree-like or dendritic pattern.

The rate of cooling has a massive impact. Slower cooling allows these grains to grow very large, while faster cooling results in a finer, smaller grain structure. This variation occurs throughout a single cast part, with the surface cooling faster than the core.

Wrought vs. Cast Microstructure

A wrought material, like a forged steel bar, starts as a cast ingot but is then mechanically worked with immense pressure. This process breaks down the large, inconsistent cast grains and realigns them into a very fine, uniform, and elongated structure. This refined microstructure is the primary reason wrought materials are often stronger.

Key Property Changes in Cast vs. Wrought Materials

Because of these microstructural differences, the same alloy will exhibit different properties depending on whether it was cast or wrought.

Strength and Ductility

Generally, a cast material will have lower tensile strength and ductility than its equivalent wrought counterpart. The larger grain size and potential for microscopic defects in castings make them more susceptible to fracture under load.

Fatigue Resistance

This is a critical distinction. Fatigue is failure from repeated cycles of loading and unloading. Castings can have lower fatigue resistance because of the inherent possibility of internal defects like porosity (tiny gas bubbles) or shrinkage voids. These defects act as stress concentrators, creating points where cracks can easily initiate and grow.

Anisotropy (Directional Properties)

This is one area where casting has a distinct advantage. Because the grains in a casting form and grow in a relatively random orientation, the final part is typically isotropic—it has the same strength and properties in all directions.

Wrought materials, by contrast, are anisotropic. Their grains are aligned in the direction of working, making them very strong along that axis but weaker in other directions.

Understanding the Trade-offs

Choosing casting is not about accepting inferior properties; it's about making a deliberate engineering trade-off to gain significant advantages in other areas.

The Inevitability of Defects

While modern casting processes are highly controlled, the risk of microscopic defects is inherent to solidifying liquid metal. High-quality foundries use techniques like vacuum casting and hot isostatic pressing (HIP) to minimize these issues, but the possibility always exists and must be accounted for in design.

"As-Cast" vs. Heat Treatment

The properties of a part directly out of the mold (the "as-cast" condition) are only a baseline. Post-casting heat treatments like annealing, normalizing, or quenching and tempering are almost always used. These processes can refine the grain structure, relieve internal stresses, and dramatically improve the material's strength and toughness, often closing the performance gap with wrought materials.

The Primary Driver: Cost and Complexity

The overwhelming reason to choose casting is its ability to produce complex, near-net-shape parts efficiently. It is far cheaper and faster to create an intricate shape like an engine block or valve body by casting it than by machining it from a solid block of metal. This reduces material waste and subsequent machining time, providing a massive economic advantage.

Making the Right Choice for Your Application

The decision to use a cast or wrought material depends entirely on the specific demands of your project. There is no universally "better" option, only the right choice for the goal.

- If your primary focus is maximum strength and fatigue life: For critical components under high cyclical stress, like aircraft connecting rods or high-performance crankshafts, a forged wrought material is typically the superior choice.

- If your primary focus is complex geometry and cost reduction: For parts with intricate internal passages or complex external shapes, like pump housings or manifolds, casting is almost always the most economical and practical solution.

- If your primary focus is uniform, multi-directional properties: For components that experience complex loads from many directions, the isotropic nature of a casting can be a significant design advantage.

By understanding how a manufacturing process shapes a material's internal structure, you can move beyond a simple "stronger or weaker" comparison and make an informed decision that balances performance, complexity, and cost.

Summary Table:

| Property | Cast Material | Wrought Material |

|---|---|---|

| Microstructure | Large, dendritic grains | Fine, uniform, elongated grains |

| Strength & Ductility | Generally lower | Generally higher |

| Fatigue Resistance | Lower (due to potential defects) | Higher |

| Anisotropy | Isotropic (same in all directions) | Anisotropic (direction-dependent) |

| Primary Advantage | Complex geometries, cost-effective | Maximum strength, fatigue life |

Need help selecting the right material process for your lab equipment? The choice between casting and wrought materials is critical for your application's performance and cost. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific research and production needs. Whether you're working with complex cast components or high-strength wrought materials, our expertise ensures you get the right solution for optimal results. Contact our experts today to discuss how we can support your laboratory's unique requirements with precision equipment and reliable consumables.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the tolerance of a muffle furnace? A Guide to Temperature Accuracy & Uniformity

- What is the cooling rate for a muffle furnace? Achieve Optimal Cooling for Your Lab Processes

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs

- What are the uses of muffle furnace in pharmaceutical industry? Essential for Drug Purity & Safety

- How do you take care of a muffle furnace? Extend Equipment Life and Ensure Accurate Results