Yes, hardening steel absolutely causes it to change dimensions. This change is not a defect but an unavoidable physical and metallurgical consequence of the process. The steel undergoes both thermal contraction from cooling and a volumetric expansion as its internal crystal structure transforms to a harder state.

The core challenge is not that steel changes dimension during hardening, but that this change can be non-uniform, leading to distortion. Understanding the two competing forces—thermal contraction and metallurgical expansion—is the key to predicting and controlling the final shape of a part.

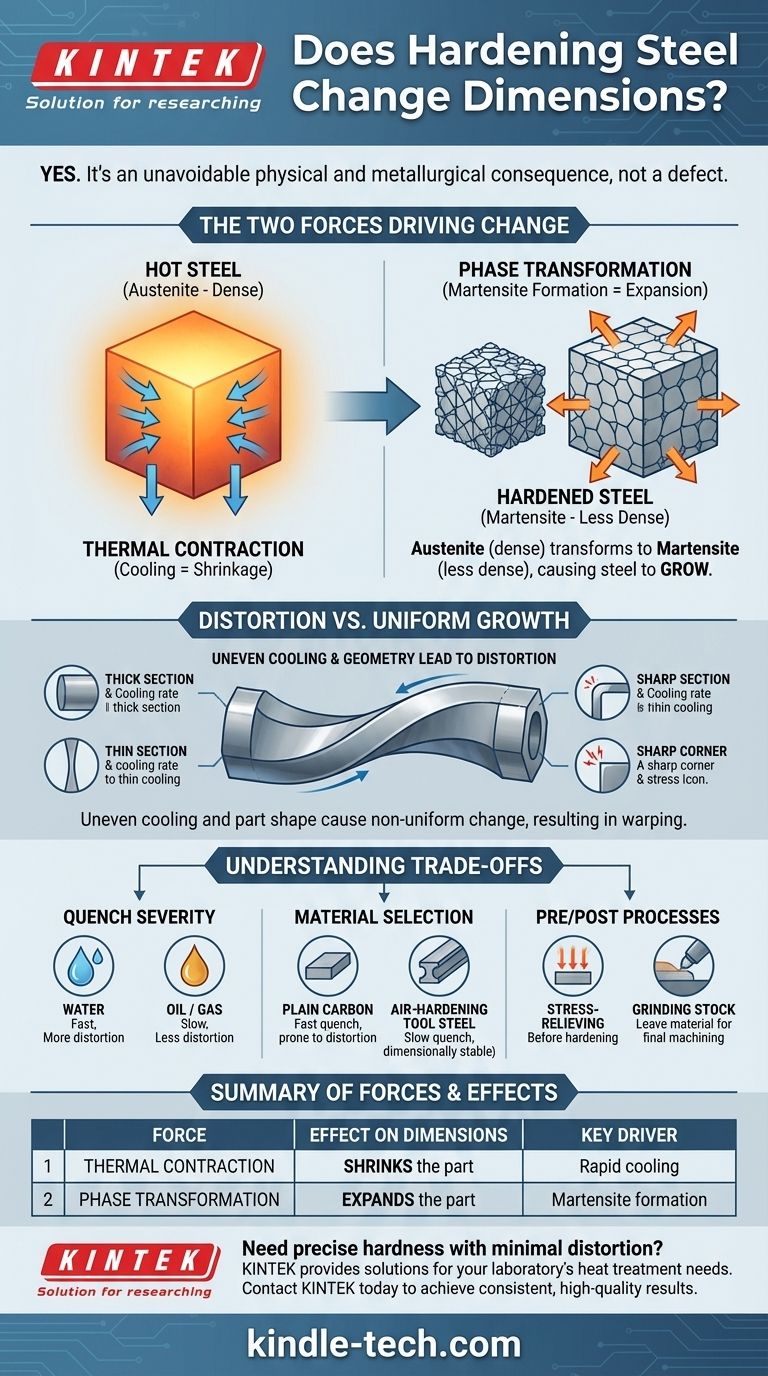

The Two Forces Driving Dimensional Change

Every part undergoing hardening is subject to two distinct and powerful forces that determine its final size and shape. These forces often work against each other.

The Impact of Thermal Contraction

As steel is quenched from a high temperature (often over 900°C), it cools rapidly. Just like any material, this rapid cooling causes it to shrink.

This process, known as thermal contraction, is the most intuitive part of the change. A hotter object is larger; a cooler object is smaller.

The Critical Role of Phase Transformation

The more significant change comes from metallurgy. At high temperatures, the steel's iron atoms are arranged in a dense, compact crystal structure called Austenite.

When the steel is rapidly quenched, this structure is trapped and forced to transform into a new structure called Martensite. Martensite is what gives hardened steel its exceptional strength and hardness.

Crucially, the Martensite crystal structure is less dense and occupies more volume than the Austenite structure it replaces. This phase transformation causes the steel to grow.

Distortion vs. Uniform Growth

If the change were perfectly uniform, you could simply account for predictable growth. The real problem is distortion (warping, twisting, or bowing), which arises because the heating and cooling are never perfectly uniform.

Uneven Cooling Rates

The surface of a steel part always cools faster than its core. This temperature differential creates immense internal stress.

The outer surface contracts and transforms to Martensite first while the core is still hot and expanded. As the core finally cools and transforms, it expands against the already hardened outer shell, creating a battle that can warp the part.

The Influence of Part Geometry

A part's shape has a massive impact on distortion.

Thin sections cool much faster than thick sections, causing them to transform at different times. Features like sharp internal corners, holes, and keyways act as stress concentrators, making them highly susceptible to cracking or distortion.

Understanding the Trade-offs

Controlling dimensional change requires managing a series of trade-offs. The goal is to achieve the required hardness without introducing unacceptable distortion.

Quench Severity

The speed of the quench is the most critical variable. A faster quench (like in water or brine) produces maximum hardness but also creates the most severe thermal shock and the highest risk of distortion and cracking.

Slower quenches (in oil or gas) are gentler on the part, significantly reducing distortion. However, they may not achieve the same level of hardness, especially in lower-alloy steels.

Material Selection

Different steel alloys are designed for different hardening responses. Plain carbon steels require a very fast quench and are prone to distortion.

In contrast, air-hardening tool steels (like A2) are alloyed to transform into Martensite with a much slower cooling rate. This drastically reduces thermal shock and makes them far more dimensionally stable.

Pre- and Post-Hardening Processes

To ensure a predictable outcome, you must consider the entire manufacturing process. Stress-relieving the part after rough machining but before final hardening can remove stresses induced by the machining itself.

For parts with extremely tight tolerances, it is standard practice to leave a small amount of extra material (grinding stock) on critical surfaces. This allows for final grinding after heat treatment to bring the part to its precise final dimension.

Making the Right Choice for Your Project

Your strategy for managing dimensional change depends entirely on the part's requirements.

- If your primary focus is maximum hardness and wear resistance: You must accept a higher potential for distortion and plan for post-hardening finishing like grinding to achieve final tolerances.

- If your primary focus is dimensional stability and tight tolerance: Select an air-hardening steel, design the part with uniform cross-sections and generous radii, and use a slower, controlled quench.

- If you are balancing cost and performance for a general-purpose part: An oil quench on a suitable alloy steel is often the best compromise, but always leave a small allowance for final machining on critical dimensions.

Treating heat treatment as an integral step in the design process, not an afterthought, is the definitive way to achieve consistent and successful results.

Summary Table:

| Force | Effect on Dimensions | Key Driver |

|---|---|---|

| Thermal Contraction | Shrinks the part | Rapid cooling from high temperature |

| Phase Transformation | Expands the part | Formation of less-dense Martensite |

Need to achieve precise hardness with minimal distortion?

Hardening steel is a delicate balance. The experts at KINTEK specialize in providing the right lab equipment and consumables to help you control the hardening process. Whether you're working with air-hardening steels or need precise quench control, we have the solutions for your laboratory's needs.

Contact KINTEK today to discuss how we can help you achieve consistent, high-quality results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing