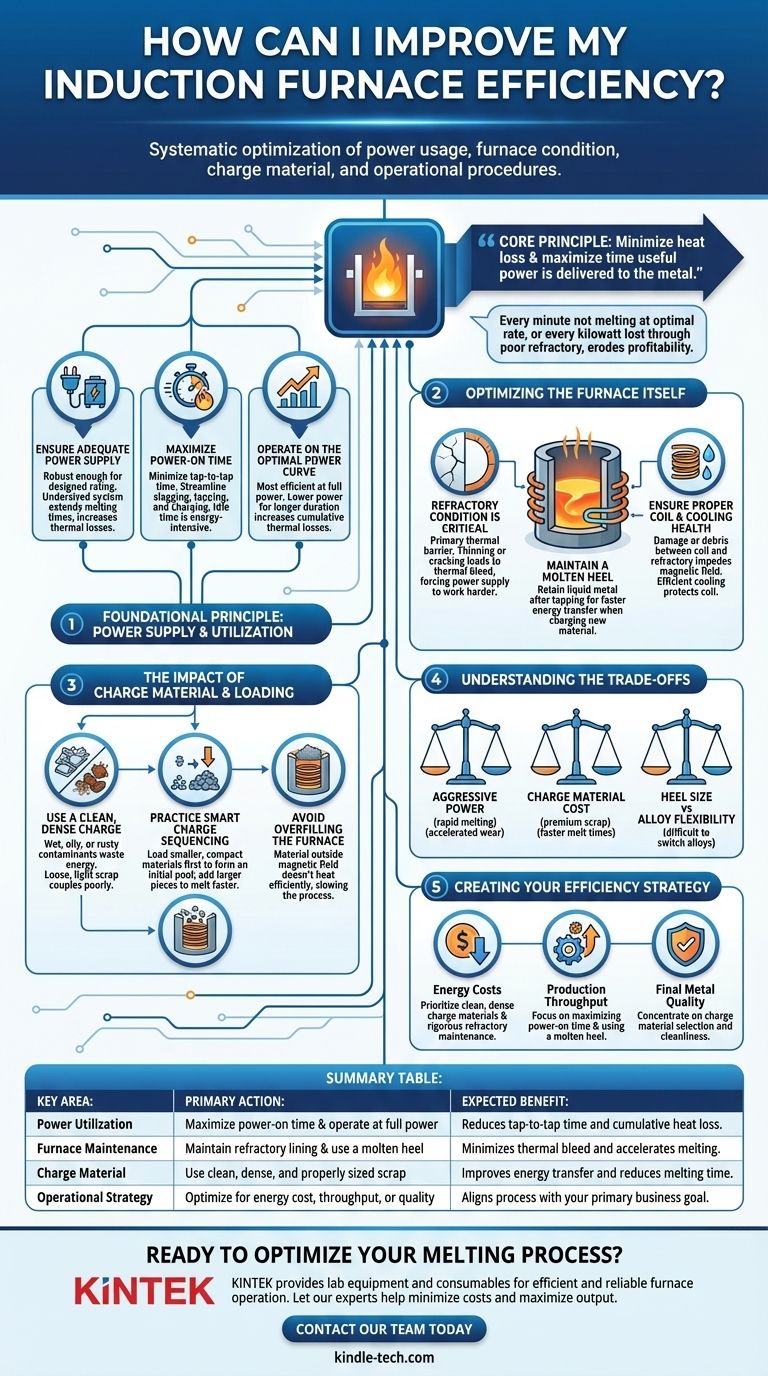

Improving induction furnace efficiency is not about a single equipment upgrade but a systematic optimization of your entire melting process. True gains are found by analyzing your power usage, the physical condition of your furnace, the quality of your charge material, and the discipline of your operational procedures.

The core principle of induction furnace efficiency is minimizing heat loss and maximizing the time that useful power is being delivered to the metal. Every minute the furnace is on but not melting at its optimal rate, or every kilowatt lost through a poor refractory, directly erodes your profitability.

Foundational Principle: Power Supply and Utilization

The efficiency of your melt begins with how you manage and apply electrical power. Simply having enough power is the first step, but how you use it is what truly matters.

Ensure Adequate Power Supply

Your power supply must be robust enough to run the furnace at its designed rating. An undersized system that struggles to deliver the required voltage and current will extend melting times, leading to massive thermal losses as the furnace radiates heat while it slowly works.

Maximize Power-On Time

An induction furnace is most efficient when it is actively melting. The goal is to minimize tap-to-tap time by streamlining the process of slagging, tapping the molten metal, and charging the next batch. Idle time or holding metal at temperature is incredibly energy-intensive.

Operate on the Optimal Power Curve

Induction furnaces are generally most efficient when run at or near full power. Operating at a lower power setting for a longer duration is less efficient because cumulative thermal losses over that extended time will be much greater.

Optimizing the Furnace Itself

The physical state of your furnace components has a direct and significant impact on energy consumption. Neglecting maintenance is a direct cause of inefficiency.

Refractory Condition is Critical

The refractory lining is your primary thermal barrier. As it thins, wears, or cracks, heat escapes from the molten bath to the water-cooled coil and furnace shell. This thermal "bleed" means the power supply must work harder and longer just to maintain temperature, let alone melt new material.

Maintain a Molten Heel

Retaining a "heel" of liquid metal after tapping can dramatically improve efficiency. Charging new, solid material into a molten bath provides far better and faster energy transfer than starting with a completely cold, empty crucible.

Ensure Proper Coil and Cooling Health

The induction coil creates the magnetic field that heats the metal. Any damage, debris, or grout between the coil and the refractory can impede this field and reduce energy transfer. Likewise, an efficient cooling system is vital to protect the coil and maintain its electrical properties.

The Impact of Charge Material and Loading

What you put into the furnace and how you put it in are just as important as the furnace itself. The charge is not just raw material; it is part of the electrical circuit.

Use a Clean, Dense Charge

Charge materials that are wet, oily, or excessively rusty waste enormous amounts of energy. The furnace must first burn off these contaminants before it can begin melting the metal. Loose, light scrap also couples poorly with the magnetic field, leading to slow and inefficient initial melting.

Practice Smart Charge Sequencing

The loading process itself impacts efficiency. A common best practice is to load smaller, more compact materials first to form an initial molten pool quickly. Larger, heavier pieces can then be added to this pool, where they will melt much faster.

Avoid Overfilling the Furnace

Filling the furnace far above the top of the induction coil is counterproductive. The material outside the effective magnetic field will not heat efficiently and will only melt through contact with the molten bath below, slowing the overall process.

Understanding the Trade-offs

Pursuing maximum efficiency often involves balancing competing priorities. Understanding these trade-offs is key to making the right operational decisions for your facility.

Aggressive Power vs. Refractory Life

Running the furnace at maximum power for rapid melting is highly energy-efficient, but the intense thermal and physical turbulence can accelerate the wear on your refractory lining. This creates a trade-off between energy savings per melt and the long-term cost of more frequent furnace relining.

Charge Material Cost vs. Energy Savings

Purchasing premium, clean, and size-sorted scrap is more expensive upfront. However, it can lead to substantial savings through lower energy consumption, faster melt times, reduced slag handling, and improved final metal chemistry.

Heel Size vs. Alloy Flexibility

Using a large molten heel is excellent for thermal efficiency but can make it difficult to switch between different metal alloys without a lengthy and costly process of completely emptying the furnace or heavily diluting the new charge.

Creating Your Efficiency Strategy

To improve efficiency, you must define your primary goal. Different objectives require focusing on different parts of the melting process.

- If your primary focus is reducing energy costs: Prioritize using clean, dense charge materials and performing rigorous, scheduled maintenance on your refractory lining.

- If your primary focus is increasing production throughput: Focus on maximizing power-on time by optimizing your tap-to-tap procedures and using a molten heel to accelerate each new melt cycle.

- If your primary focus is improving final metal quality: Concentrate on the selection and cleanliness of your charge material to minimize the introduction of impurities, reduce slag, and achieve consistent results.

A systematic and disciplined approach to furnace operation transforms energy consumption from a fixed cost into a manageable, optimized variable.

Summary Table:

| Key Area for Improvement | Primary Action | Expected Benefit |

|---|---|---|

| Power Utilization | Maximize power-on time & operate at full power | Reduces tap-to-tap time and cumulative heat loss |

| Furnace Maintenance | Maintain refractory lining & use a molten heel | Minimizes thermal bleed and accelerates melting |

| Charge Material | Use clean, dense, and properly sized scrap | Improves energy transfer and reduces melting time |

| Operational Strategy | Optimize for energy cost, throughput, or quality | Aligns process with your primary business goal |

Ready to optimize your melting process? The strategies above are just the beginning. At KINTEK, we specialize in providing the lab equipment and consumables that support efficient and reliable furnace operation. Our experts can help you select the right tools and materials to minimize energy costs and maximize your output. Contact our team today to discuss how we can support your specific laboratory needs and boost your furnace's performance.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance