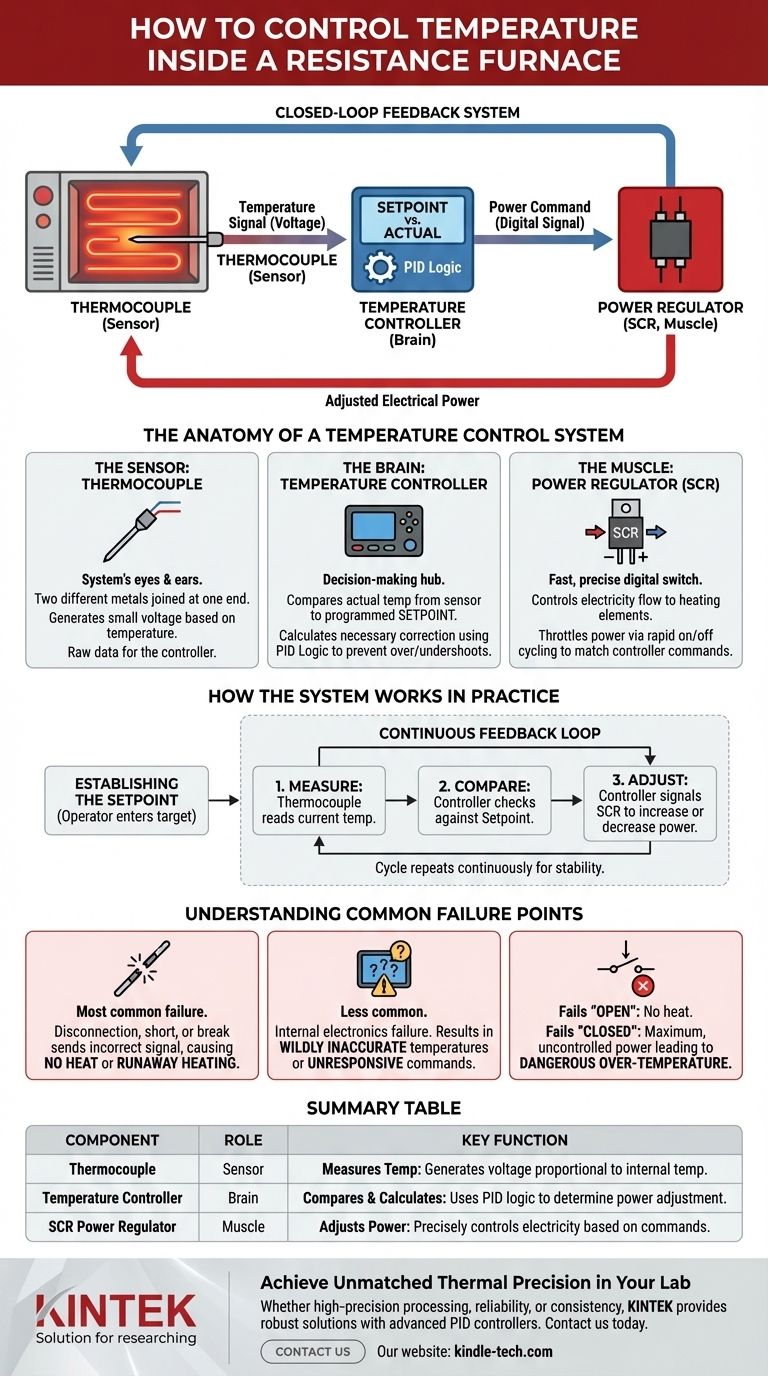

At its core, temperature inside a resistance furnace is controlled through a closed-loop feedback system. This system constantly measures the internal temperature, compares it to a desired setpoint, and precisely adjusts the electrical power supplied to the heating elements to either increase or decrease the heat output, ensuring the target temperature is maintained accurately.

The key to furnace temperature control is not a single component, but a dynamic system: a sensor (thermocouple), a controller (the brain), and a power regulator (the muscle) working together to continuously manage energy flow and maintain thermal stability.

The Anatomy of a Temperature Control System

To truly understand how control is achieved, you must understand the three critical components that form the feedback loop. Each has a distinct and vital role.

The Sensor: The Thermocouple

A thermocouple is the system's eyes and ears inside the furnace. It's a sensor made of two different metals joined at one end.

This junction produces a small voltage that changes predictably with temperature. This voltage signal is the raw data that tells the control system the exact temperature inside the furnace at any given moment.

The Brain: The Temperature Controller

The temperature signal from the thermocouple is sent to the temperature controller. This is the decision-making hub of the system.

The controller performs one crucial task: it compares the actual temperature (from the thermocouple) to the setpoint temperature that you have programmed. Based on the difference, it calculates the necessary correction. Modern controllers often use sophisticated PID (Proportional-Integral-Derivative) logic to make these decisions intelligently, preventing temperature overshoots and undershoots.

The Muscle: The Power Regulator

The controller's decision is sent as a command to a power regulator, most commonly a Silicon-Controlled Rectifier (SCR).

The SCR acts like an extremely fast and precise digital switch. It controls the amount of electricity flowing to the heating elements by rapidly turning the power on and off, many times per second. By changing the on-off duty cycle, it effectively "throttles" the power, delivering just enough energy to the heating elements to follow the controller's commands.

How the System Works in Practice

These components work in a continuous, dynamic cycle to achieve and hold a target temperature.

Establishing the Setpoint

The process begins when an operator enters a desired temperature or a time-based temperature profile (a "curve") into the controller. This becomes the target the system will work to achieve.

The Continuous Feedback Loop

Once engaged, the loop is constant:

- Measure: The thermocouple measures the current furnace temperature.

- Compare: The controller compares this measurement to the setpoint.

- Adjust: If the temperature is too low, the controller tells the SCR to allow more power to the heating elements. If it's too high, it reduces the power.

This cycle repeats continuously, making micro-adjustments to hold the temperature with remarkable stability.

Understanding Common Failure Points

A failure in any part of this system will compromise temperature control. Understanding these weak points is key to effective troubleshooting.

Thermocouple Issues

The thermocouple is the most common point of failure as it resides in the harshest environment. A disconnection, short circuit, or break in the thermocouple wire will send an incorrect or non-existent signal to the controller, leading to either no heat or runaway heating.

Controller Malfunction

While less common, the temperature controller itself can fail. If the furnace temperature is wildly inaccurate or unresponsive to commands, the controller's internal electronics may be the cause. Repair or replacement should be done according to the manufacturer's manual.

Power Regulator (SCR) Failure

A failed SCR can lead to two outcomes. If it fails "open," no power will reach the heating elements, and the furnace will not heat up. If it fails "closed," it will send maximum, uncontrolled power to the elements, creating a dangerous over-temperature situation.

Making the Right Choice for Your Process

The sophistication of your control system should match the demands of your application.

- If your primary focus is high-precision material processing: Invest in a system with an advanced PID controller that allows for fine-tuning and programmable temperature curves.

- If your primary focus is operational reliability: Keep spare thermocouples on hand and familiarize your team with troubleshooting the common failure points.

- If your primary focus is process consistency across batches: Select a digital controller that can save and reuse specific heating profiles to ensure repeatable results.

By understanding this control system as an interconnected whole, you gain mastery over the heating process and ensure your furnace performs reliably and precisely for its intended task.

Summary Table:

| Component | Role | Key Function |

|---|---|---|

| Thermocouple (Sensor) | Measures Temperature | Generates a voltage signal proportional to the furnace's internal temperature. |

| Temperature Controller (Brain) | Compares & Calculates | Compares actual temperature to setpoint and uses PID logic to determine the required power adjustment. |

| SCR Power Regulator (Muscle) | Adjusts Power | Precisely controls electrical power to the heating elements based on the controller's commands. |

Achieve Unmatched Thermal Precision in Your Lab

Whether your priority is high-precision material processing, operational reliability, or batch-to-batch consistency, the right temperature control system is critical. KINTEK specializes in lab furnaces and equipment, providing robust solutions tailored to your specific laboratory needs.

Our experts can help you select a system with the advanced PID controllers and reliable components you need for accurate and repeatable results.

Contact us today to discuss your application and ensure your processes are built on a foundation of precise thermal control.

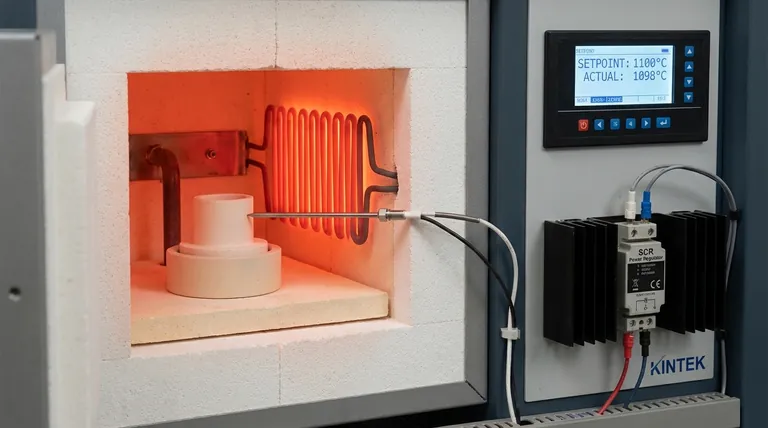

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do high-temperature furnaces and ceramic crucibles impact Li-ion battery stability? Master Precision Synthesis

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics

- What is the use of a digital muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components

- What is the use of furnace in laboratory? Unlock Material Transformation for Your Research