In short, controlling the temperature of an induction heater is achieved by regulating the amount of energy delivered to the workpiece over time. The most common methods are manually adjusting the heater's power output and heating duration, or implementing a closed-loop system that uses a temperature sensor, such as an infrared pyrometer or a thermocouple, to automatically adjust the power and maintain a specific temperature.

Unlike a conventional oven, an induction heater does not have a simple temperature dial. True control is not about setting a temperature, but about precisely managing the rate of energy transfer and using feedback to achieve a thermal goal.

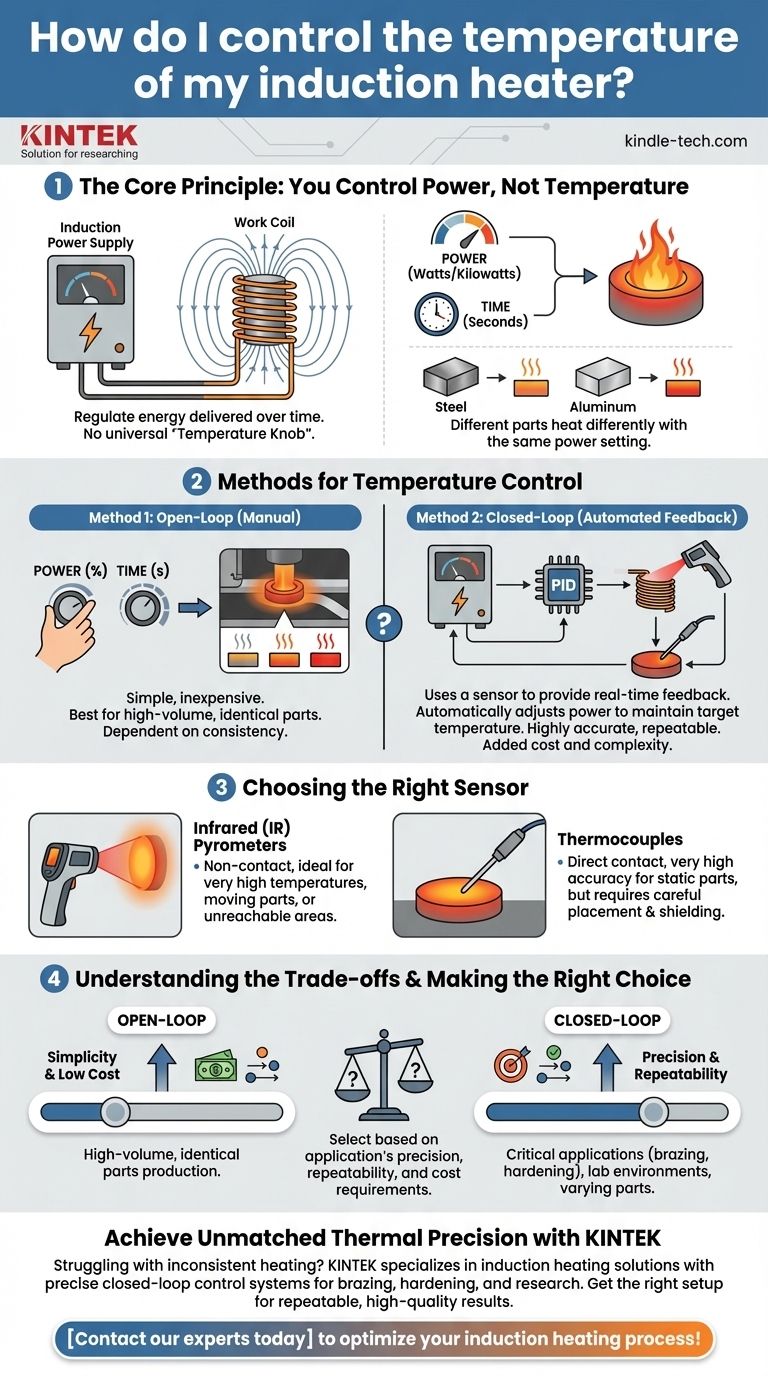

The Core Principle: You Control Power, Not Temperature

An induction heater's primary job is to transfer energy, measured in watts or kilowatts, from the power supply to your workpiece through a magnetic field. Understanding this concept is the key to mastering temperature control.

How Power Translates to Heat

The induction power supply generates a high-frequency alternating current in the work coil. This creates a powerful, rapidly changing magnetic field around the coil.

When you place a conductive material (like steel) into this field, the field induces electrical currents, known as eddy currents, within the part. The material's natural resistance to the flow of these currents generates precise, instantaneous heat.

The temperature of the part rises as long as power is applied. The rate of this rise depends on the power level, the material's properties, and the part's mass.

Why a "Temperature Knob" Doesn't Exist

The same power setting will heat different parts to different temperatures. A small part will heat much faster than a large one, and a magnetic steel part will heat differently than an aluminum one.

Because the system cannot know the properties of the workpiece, it cannot have a universal temperature setting. It only knows how much power it is delivering. Control is achieved by telling the system how to apply that power.

Methods for Temperature Control

There are two primary strategies for controlling temperature: open-loop (manual) and closed-loop (automated feedback).

Method 1: Open-Loop (Power & Time)

This is the simplest method. You control two variables: the power supply's output percentage and the heating time.

Through trial and error, you determine that setting the power to, for example, 60% for 8.5 seconds achieves your desired temperature. This is an "open-loop" system because the heater receives no feedback; it simply executes the command.

This method works well for high-volume, highly repeatable processes where the part, its position in the coil, and its starting temperature are always identical.

Method 2: Closed-Loop (Sensor Feedback)

This is the most accurate and reliable method for precise thermal processes. A closed-loop system uses a temperature sensor to measure the part's temperature in real-time and feed that data back to the power supply's controller.

The controller (often a PID controller) continuously compares the actual temperature to your setpoint. It then automatically adjusts the power output—ramping up, holding steady, or shutting off—to precisely reach and maintain the target temperature.

Choosing the Right Sensor

The quality of your closed-loop control depends entirely on the quality of your sensor feedback.

- Infrared (IR) Pyrometers: These non-contact sensors measure temperature by detecting the infrared energy an object emits. They are ideal for very high temperatures, moving parts, or situations where direct contact is impossible.

- Thermocouples: These sensors must be in direct physical contact with the part. They offer very high accuracy for static parts but can be difficult to place correctly and may be susceptible to interference from the magnetic field if not properly shielded or positioned.

Understanding the Trade-offs

Each control method comes with distinct advantages and disadvantages that make it suitable for different applications.

The Simplicity of Open-Loop

Open-loop control is inexpensive and straightforward to implement, as it only requires a basic power supply with a timer.

However, it is entirely dependent on consistency. Any variation in the part's initial temperature, mass, or position within the coil will result in a different final temperature, leading to inconsistent quality.

The Precision of Closed-Loop

Closed-loop control is highly accurate, repeatable, and adaptable. It automatically compensates for minor variations in part placement or starting temperature to ensure the correct outcome every time.

The primary drawback is the added cost and complexity. You must invest in a quality sensor and a power supply with a PID controller capable of processing the feedback signal.

Sensor Placement is Critical

A closed-loop system is only as good as its measurement. An IR pyrometer aimed at the wrong spot or a thermocouple making poor contact will provide false data, causing the system to either under- or overheat the part. The sensor must be focused on the specific area where temperature is most critical.

Making the Right Choice for Your Process

Your application's requirements for precision, repeatability, and cost will determine the best control strategy.

- If your primary focus is low-cost, high-volume production of identical parts: Open-loop power and time control is often sufficient once dialed in.

- If your primary focus is high precision for critical applications like brazing, hardening, or shrink-fitting: A closed-loop system with a sensor is non-negotiable for ensuring quality and repeatability.

- If you are working in a lab or heating a variety of different parts: A closed-loop system is essential, as manual settings will not be transferable between different setups.

Ultimately, mastering induction temperature control comes from selecting the right feedback method for the precision your application demands.

Summary Table:

| Control Method | How It Works | Best For | Key Consideration |

|---|---|---|---|

| Open-Loop (Manual) | Set power level and heating time. No temperature feedback. | High-volume, identical parts; low-cost applications. | Inconsistent if part mass or position varies. |

| Closed-Loop (Automatic) | Uses a sensor (IR pyrometer/thermocouple) to provide real-time feedback to a PID controller. | Critical applications like brazing, hardening; labs with varying parts. | Sensor placement and quality are critical for accuracy. |

Achieve Unmatched Thermal Precision with KINTEK

Struggling with inconsistent heating or complex temperature control in your lab processes? KINTEK specializes in advanced lab equipment, including induction heating solutions with precise closed-loop control systems. Our expertise ensures you get the right setup for brazing, hardening, or any thermal application—delivering repeatable, high-quality results every time.

Let us help you optimize your induction heating process. Contact our experts today for a personalized solution!

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Performance Laboratory Stirrers for Diverse Applications

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the working principle of a high frequency induction furnace? Master Rapid, Clean Metal Melting

- Can copper be melting in induction furnace? Unlock Superior Melting Precision & Quality

- What is the difference between blast furnace and induction furnace? Choosing the Right Metal Melting Solution

- What is the role of VIM equipment in experimental superalloy castings? Ensure High Purity for Oxidation Research

- What is the best material for induction heating? Ferromagnetic Metals for Maximum Efficiency

- What type of furnace do I need to melt steel? The Definitive Guide to Induction Furnaces

- What is the design of an induction melting furnace? Master Contactless, Efficient Metal Melting

- What are the three main components of an induction heating system? Power Supply, Coil, and Workpiece Explained