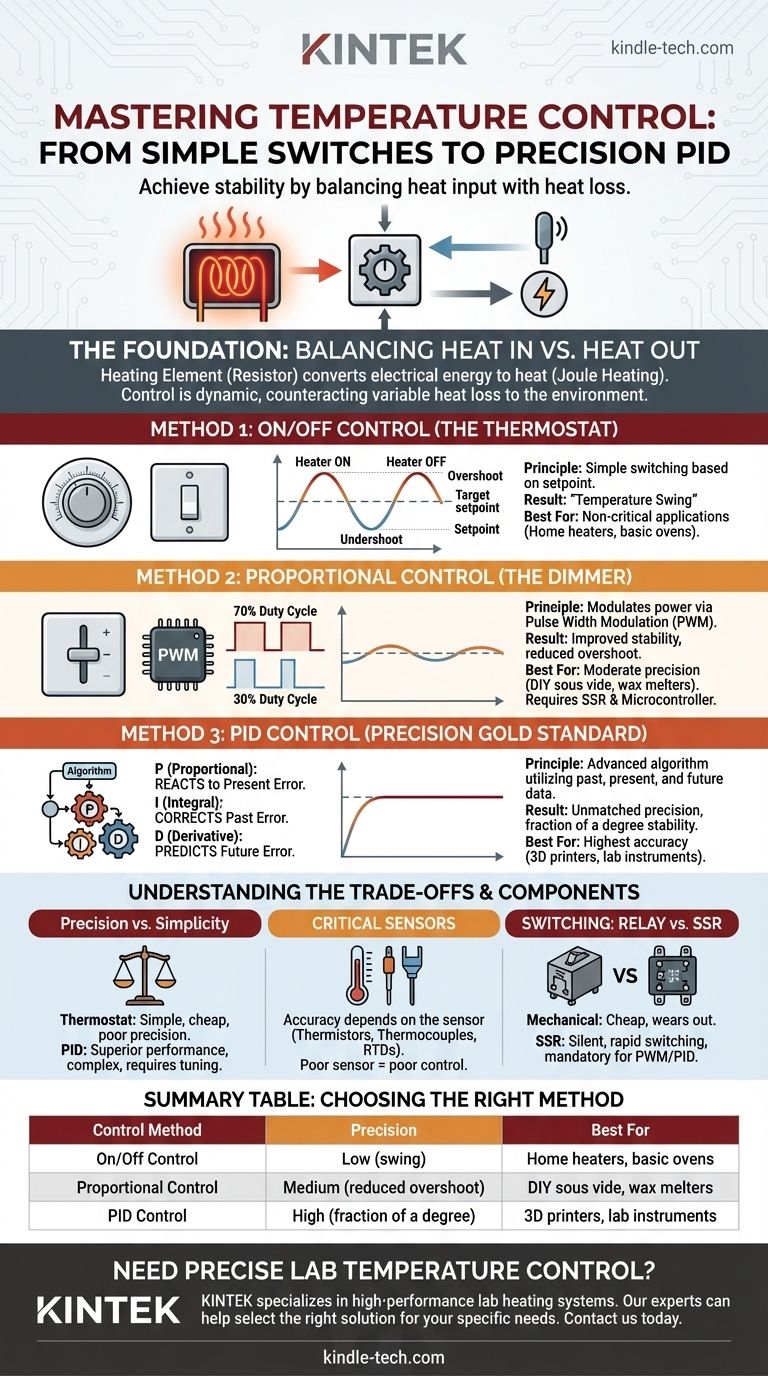

To control a heating element's temperature, you must use a control system that actively measures the temperature and adjusts the power supplied to the element. The most common methods range from simple on/off systems using thermostats to highly precise PID controllers. These systems work by creating a "closed loop," where a temperature sensor provides feedback, allowing the controller to intelligently manage the heater's output to match a desired setpoint.

The core challenge in temperature control is not just delivering power, but balancing heat input against heat loss to the environment. The method you choose—from a simple thermostat to a sophisticated PID loop—depends entirely on the level of precision and stability your application demands.

The Foundation: Balancing Heat In vs. Heat Out

A heating element is fundamentally a resistor. When electrical current flows through it, the resistance converts electrical energy into heat. This is known as Joule heating.

The Control Problem

You cannot achieve a specific temperature by simply applying a fixed voltage. An uncontrolled element will continue to heat up until it either reaches a natural equilibrium with its environment or, more likely, destroys itself.

Effective temperature control is a dynamic process. The controller's job is to constantly adjust power to counteract heat loss, which changes based on ambient temperature, airflow, and the thermal mass of the system.

Method 1: On/Off Control (The Thermostat)

This is the simplest and most common form of temperature control. It operates on a straightforward principle often found in home thermostats or basic appliances.

How It Works

A temperature sensor is connected to a switch (like a relay). When the temperature drops below your target setpoint, the controller switches the heating element fully ON. Once the temperature rises above the setpoint, the controller switches the element fully OFF.

The Result: A "Temperature Swing"

This method inevitably leads to temperature oscillation. The system will overshoot the target temperature because the element remains hot for a time after being switched off. It will then undershoot as it cools down before the controller turns the power back on.

Common Use Cases

On/off control is ideal for non-critical applications where a temperature fluctuation of a few degrees is acceptable. This includes residential heating systems, water heaters, and basic ovens.

Method 2: Proportional Control (The Dimmer Switch)

Proportional control is a significant step up from the simple on/off method. It modulates the power delivered to the heater, offering smoother and more stable temperature regulation.

Introducing Pulse Width Modulation (PWM)

Instead of being either fully on or fully off, the heater is switched on and off very rapidly. The ratio of "on" time to "off" time, known as the duty cycle, determines the average power delivered. A 70% duty cycle, for example, delivers 70% of the total power.

This requires a microcontroller (like an Arduino) and a Solid-State Relay (SSR), which can handle rapid switching without mechanical wear.

Improved Stability

A proportional controller reduces power as the temperature approaches the setpoint. This is like easing your foot off the accelerator as you approach a stoplight, dramatically reducing the overshoot seen in on/off systems.

Method 3: PID Control (The Gold Standard for Precision)

For applications demanding the highest accuracy and stability, a PID controller is the definitive solution. It is an advanced algorithm that uses a three-term calculation to minimize error and hold a temperature with extreme precision.

The Three Terms of PID

A PID controller looks at the past, present, and future of the system's temperature to make intelligent decisions.

- P (Proportional): Reacts to the present error. The further the temperature is from the setpoint, the more power it applies. This is the primary driver of the system.

- I (Integral): Corrects for past error. It accumulates small, persistent errors over time and adjusts the output to eliminate them, preventing the temperature from stabilizing slightly below the setpoint.

- D (Derivative): Predicts future error. It observes the rate of temperature change. If the temperature is rising too quickly, it reduces power before it overshoots the target, effectively damping oscillations.

Unmatched Performance

When properly "tuned," a PID loop can hold a temperature with remarkable stability, often to within a fraction of a degree of the setpoint. This makes it essential for sensitive scientific, industrial, and manufacturing processes.

Understanding the Trade-offs

Choosing a control method involves balancing complexity, cost, and performance. No single solution is best for every scenario.

Precision vs. Simplicity

A simple thermostat is cheap and easy to implement but offers poor precision. A PID controller provides superior performance but requires a microcontroller, more complex software, and a "tuning" process to optimize the P, I, and D values for your specific system.

The Critical Role of the Sensor

Your control system is only as good as its temperature sensor. A slow, inaccurate, or poorly placed sensor will cripple the performance of even the most advanced PID controller. Common sensor types include thermistors, thermocouples, and RTDs, each with different cost, range, and accuracy characteristics.

Switching: Mechanical Relay vs. SSR

Mechanical relays are inexpensive but cannot handle the rapid switching required for PWM or PID control; they will wear out and fail quickly. Solid-State Relays (SSRs) have no moving parts, are silent, and can switch millions of times, making them mandatory for any proportional or PID system.

Choosing the Right Method for Your Project

Your decision should be driven by the requirements of your specific goal.

- If your primary focus is simplicity and low cost (e.g., a reptile tank heater or simple incubator): An on/off controller with a thermostat is sufficient and effective.

- If you need good stability without extreme precision (e.g., a DIY sous vide cooker or wax melter): A proportional (PWM) controller using a microcontroller and an SSR offers a great balance of performance and complexity.

- If your primary focus is maximum precision and stability (e.g., a 3D printer hotend, reflow oven, or scientific instrument): A PID controller is the only professional choice to achieve reliable, repeatable results.

Ultimately, effective temperature control is about selecting a strategy that precisely matches the thermal demands of your system.

Summary Table:

| Control Method | Principle | Precision | Best For |

|---|---|---|---|

| On/Off Control | Simple thermostat switching | Low (temperature swing) | Home heaters, basic ovens |

| Proportional Control | PWM duty cycle modulation | Medium (reduced overshoot) | DIY sous vide, wax melters |

| PID Control | Proportional + Integral + Derivative algorithm | High (fraction of a degree) | 3D printers, lab instruments |

Need precise temperature control for your lab equipment? KINTEK specializes in high-performance lab heating systems and consumables. Whether you require simple on/off control or advanced PID loops for sensitive applications, our experts can help you select the right solution for stability and accuracy. Contact us today to discuss your specific laboratory heating needs!

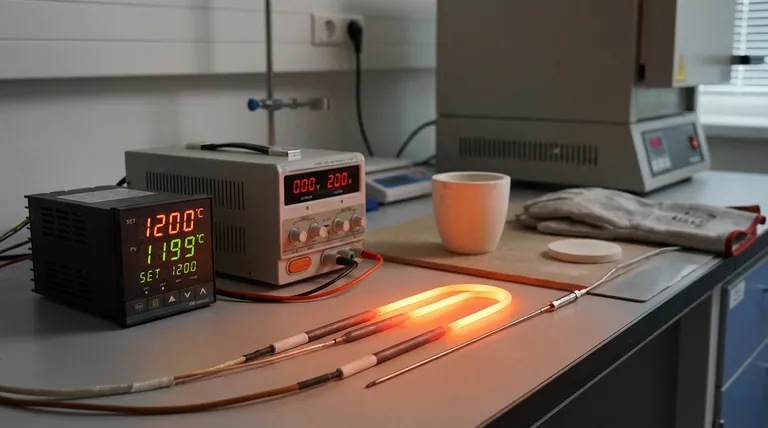

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Infrared Heating Quantitative Flat Plate Press Mold

- Double Plate Heating Press Mold for Lab

- Manual Lab Heat Press

People Also Ask

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What material is used for furnace heating? Select the Right Element for Your Process

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere