At its core, a hammer mill operates on a simple principle of brute-force impact. Material is fed into a steel chamber where a set of rotating hammers, spinning at high speed on a central rotor, strike the material repeatedly. This intense collision shatters the material, breaking it down until it is small enough to pass through a perforated screen at the bottom of the chamber.

A hammer mill achieves particle size reduction not through cutting or crushing, but through a rapid series of impacts. The final particle size is ultimately determined not by the hammers themselves, but by the size of the openings in an interchangeable screen.

The Step-by-Step Grinding Process

Understanding how a hammer mill works involves visualizing a four-stage process that happens almost instantaneously within the grinding chamber.

Step 1: Material Feeding

The process begins when the raw material is introduced into the mill, typically through an infeed chute at the top. Gravity causes the material to fall directly into the path of the rotating hammers.

Step 2: Initial Impact and Shattering

As the material enters the grinding chamber, it is immediately struck by hammers moving at extremely high speeds. This first impact is responsible for the initial fracture, shattering the material in mid-air.

Step 3: Secondary Reduction

The force of the impact propels the broken particles against the inner wall of the grinding chamber. This collision causes further reduction in size. The material continues to be struck by the hammers and collide with the chamber wall and other particles until it is pulverized.

Step 4: Sizing and Discharge

The ground material is continuously forced against a perforated screen that forms part of the chamber wall. Particles that have been reduced to a size smaller than the screen's holes can pass through and are discharged as the final product. Larger particles remain in the chamber for further impacts.

Key Components and Their Function

The efficiency and output of a hammer mill are dictated by the interplay of its primary components.

The Rotor and Hammers

This is the heart of the machine. The rotor is a spinning shaft to which the hammers are attached. The hammers are typically free-swinging and often four-way reversible, meaning they can be rotated to present a new striking face as they wear down, significantly extending their operational life.

The Grinding Chamber

This is the heavy-duty steel casing that encloses the rotor and hammers. For processing tough or abrasive materials, these chambers are often fitted with replaceable internal wear plates to protect the main housing from damage.

The Perforated Screen

The screen acts as the classifier, controlling the final output. It is an interchangeable part with holes of a specific size. A wide selection of screens allows operators to produce the exact desired finished particle size for a given application.

Understanding the Trade-offs and Variables

A hammer mill is a powerful tool, but its performance depends on matching its configuration to the material being processed.

The Screen Dictates the Output

The single most important factor for controlling the final particle size is the screen. A smaller hole size results in a finer grind but typically reduces the throughput (the rate of production).

Hammer Type and Speed Matter

The shape, number, and speed of the hammers influence the grinding action. Blunt hammers provide more of a shattering impact, ideal for crystalline materials, while sharper-edged hammers can help with more fibrous materials.

Material Characteristics are Crucial

The effectiveness of a hammer mill is highly dependent on the input material. It excels at processing dry, brittle, and non-abrasive materials. Sticky, oily, or highly abrasive materials can pose challenges, causing screen blockages or rapid component wear.

Making the Right Choice for Your Goal

To optimize a hammer mill for your specific needs, focus on the component that has the most influence over your desired outcome.

- If your primary focus is achieving a precise particle size: Your most critical choice is the perforated screen, as it directly controls the maximum size of the finished product.

- If your primary focus is processing abrasive materials: Ensure the mill is equipped with hardened, replaceable wear plates and uses durable, reversible hammers to manage maintenance costs.

- If your primary focus is maximizing throughput: You must select the largest screen size that meets your product requirements and carefully balance the material feed rate with the mill's motor power.

Ultimately, the hammer mill is a remarkably versatile and effective machine for high-impact particle size reduction.

Summary Table:

| Component | Function |

|---|---|

| Rotor & Hammers | Spinning shaft with attached hammers that strike and shatter material. |

| Grinding Chamber | Enclosed steel casing where impact and reduction occur. |

| Perforated Screen | Interchangeable screen that controls final particle size by allowing only small particles to pass. |

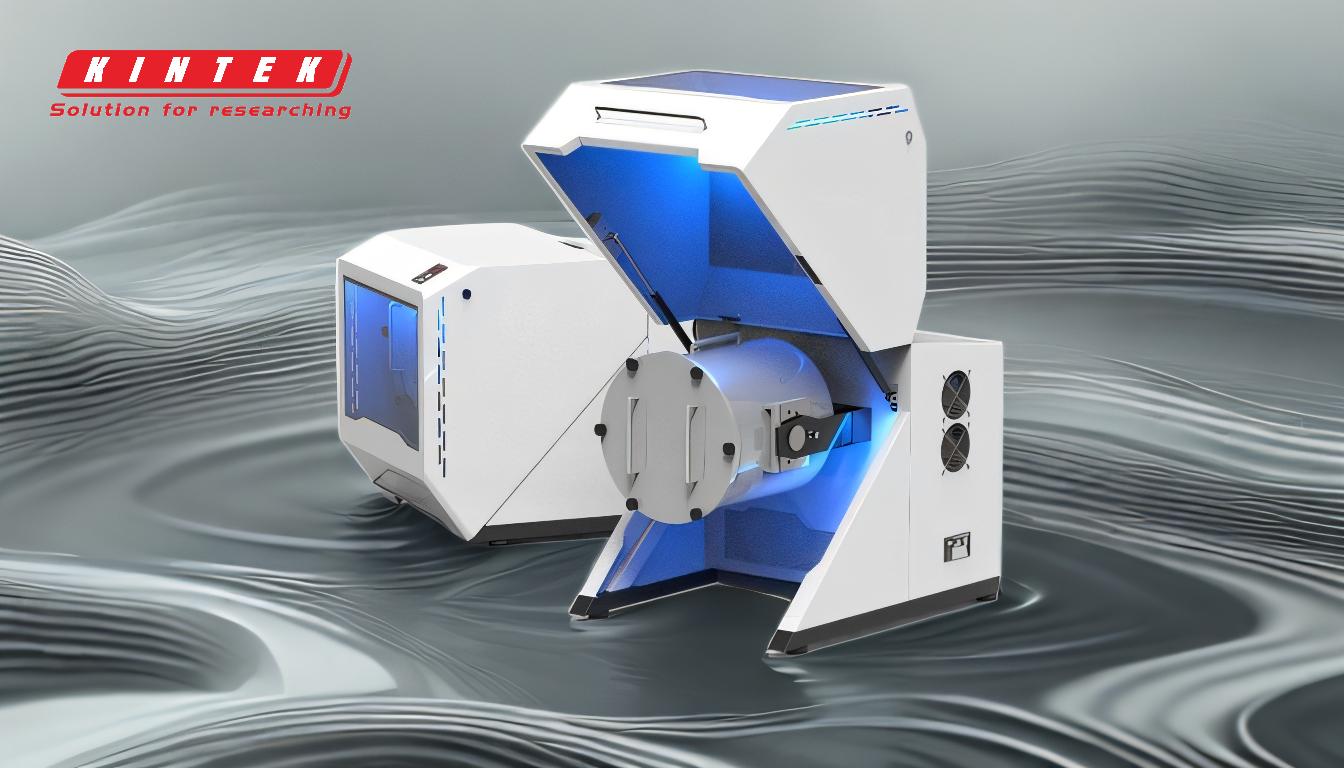

Ready to optimize your particle size reduction process? KINTEK specializes in high-quality lab equipment, including hammer mills designed for efficiency and durability. Whether your goal is precise particle sizing, handling abrasive materials, or maximizing throughput, our experts can help you select the perfect solution for your laboratory's unique needs. Contact us today to discuss your application and discover the KINTEK advantage!

Related Products

- Laboratory Sealed Hammer Crusher for Efficient Sample Preparation

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- How does particle size affect XRF? Achieve Accurate and Repeatable Elemental Analysis

- Why is crushing and grinding a sample necessary? Ensure Accurate & Reliable Material Analysis

- How does a Hammermill shredder work? Pulverize Materials with High-Impact Force

- What does pulverized material mean? Unlock Faster Reactions and Uniform Blends

- What is the purpose of a pulverizer? Unlock Material Potential with Fine Grinding