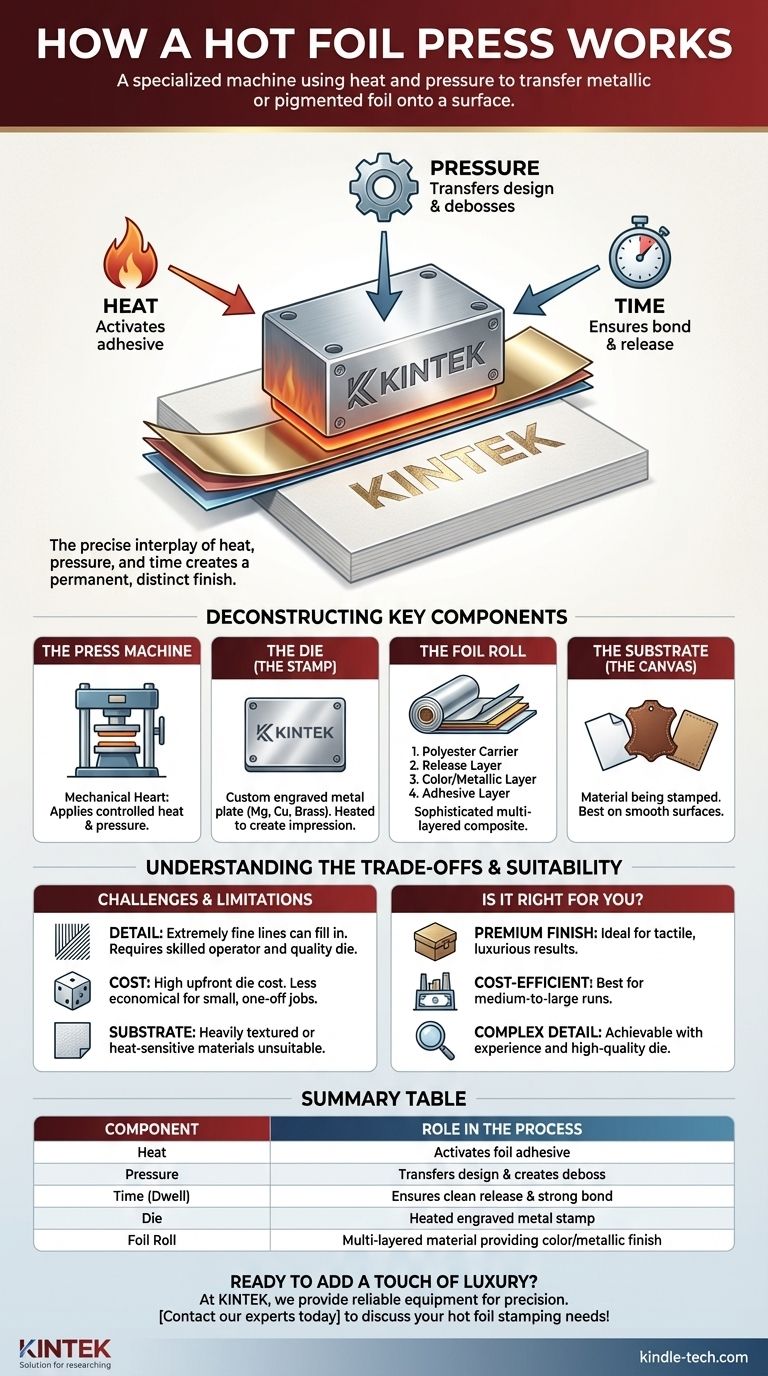

At its core, a hot foil press is a specialized machine that uses a combination of heat and pressure to transfer a thin layer of metallic or pigmented foil onto a surface. The process involves a heated metal die, engraved with a specific design, which presses the foil against the substrate (like paper or cardstock), causing the design to permanently bond to the material with a distinct, slightly indented finish.

The entire process hinges on the precise interplay of three critical variables: heat, which activates the foil's adhesive layer; pressure, which transfers the design and creates the impression; and time, which ensures a clean release and a permanent bond.

The Three Core Elements of Hot Foil Stamping

To truly understand how a hot foil press works, you must understand the three physical forces it manipulates. Getting the balance right is what separates a poor result from a perfect one.

Heat: The Activator

Heat is applied to the metal die, which then makes contact with the foil. The foil itself is a multi-layered material, and its bottom layer is a heat-activated adhesive.

The temperature must be precise. Too little heat will result in an incomplete or patchy transfer, as the adhesive won't fully activate. Too much heat can cause the foil to bubble or "bleed" outside the intended design area, creating a messy, undefined impression.

Pressure: The Transfer Mechanism

The press applies controlled physical force, pushing the heated die and foil into the substrate. This pressure serves two functions.

First, it ensures clean and complete contact between the foil and the surface material, forcing the activated adhesive to bond securely. Second, it creates the characteristic "debossed" or indented effect that gives foil stamping its unique tactile quality.

Time: The Bonding Agent

"Dwell time" refers to the duration the heated die remains pressed against the foil and substrate. This is a critical, though brief, period.

The dwell time must be just long enough for the heat to fully activate the adhesive and for the pressure to create a strong bond. If the die is lifted too quickly, the foil may not adhere properly. If it's held too long, the excess heat can ruin the finish.

Deconstructing the Key Components

The process is a mechanical symphony between several key parts, each with a specific role.

The Press Machine

This is the mechanical heart of the operation. While designs vary (from simple hand-operated models to large pneumatic or hydraulic industrial machines), they all serve to apply controlled, even pressure and regulate the temperature of the die.

The Die (The Stamp)

The die is a custom metal plate—typically made of magnesium, copper, or brass—that has been chemically etched or engraved with your reversed design. It is heated and serves as the stamp that creates the impression. The material of the die often determines the level of detail that can be achieved.

The Foil Roll (The "Ink")

Foil is not simply a thin sheet of metal. It's a sophisticated composite material, typically consisting of four layers:

- Polyester Carrier: A clear, stable top layer that holds everything together.

- Release Layer: A chemical coating that separates from the carrier when heat is applied.

- Color/Metallic Layer: The actual foil finish that you see (e.g., gold, silver, pigment).

- Adhesive Layer: The heat-sensitive glue that bonds the color layer to the substrate.

The Substrate (The Canvas)

This is the material being stamped. While paper and cardstock are most common, hot foil stamping can also be used on leather, book cloth, and certain plastics. The best results are typically achieved on smoother surfaces that can withstand the necessary heat and pressure.

Understanding the Trade-offs

Hot foil stamping creates a premium effect, but it's essential to understand its practical limitations.

Detail and Complexity

Extremely fine lines or small, intricate text can be challenging to reproduce cleanly. If the pressure or heat is even slightly off, these fine details can "fill in," losing their definition. This requires a highly skilled operator and often a more expensive, precisely engraved brass die.

Cost and Setup

The primary upfront cost is the creation of the custom metal die. This makes hot foil stamping less economical for very small, one-off jobs. It is most cost-effective for medium-to-large production runs where the die cost is distributed over many units.

Substrate Limitations

The process is not suitable for all materials. Heavily textured papers can result in an uneven or broken foil transfer. Likewise, materials that cannot withstand temperatures of around 250°F (120°C) without melting or warping cannot be used.

Is Hot Foil Stamping Right for Your Project?

Consider your ultimate goal to determine if this process is the correct choice.

- If your primary focus is a premium, tactile, and luxurious finish: Hot foil stamping is one of the best available methods for achieving this effect.

- If your primary focus is cost-efficiency on a very small run: The setup cost of the custom die may make digital foil or other alternatives more practical.

- If your primary focus is reproducing extremely fine or complex details: It is achievable, but you must work with an experienced print provider and invest in a high-quality die.

By combining heat, pressure, and precision, hot foil stamping offers a unique and impactful finish that digital printing cannot replicate.

Summary Table:

| Component | Role in the Process |

|---|---|

| Heat | Activates the foil's adhesive layer for bonding. |

| Pressure | Transfers the design and creates the debossed effect. |

| Time (Dwell) | Ensures a clean release and a permanent, strong bond. |

| Die | The heated metal stamp engraved with your design. |

| Foil Roll | The multi-layered material that provides the color/metallic finish. |

Ready to add a touch of luxury to your projects?

At KINTEK, we specialize in providing reliable lab equipment and consumables for professionals who demand precision. Whether you're in printing, packaging, or product development, our expertise ensures you get the right tools for perfect results every time.

Let's bring your premium designs to life. Contact our experts today to discuss your specific hot foil stamping needs!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts

- What temp does THC bind with oil? Mastering the Two-Stage Process for Perfect Potency

- How does resistance create heat? Unlock the Science of Efficient Energy Conversion

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating