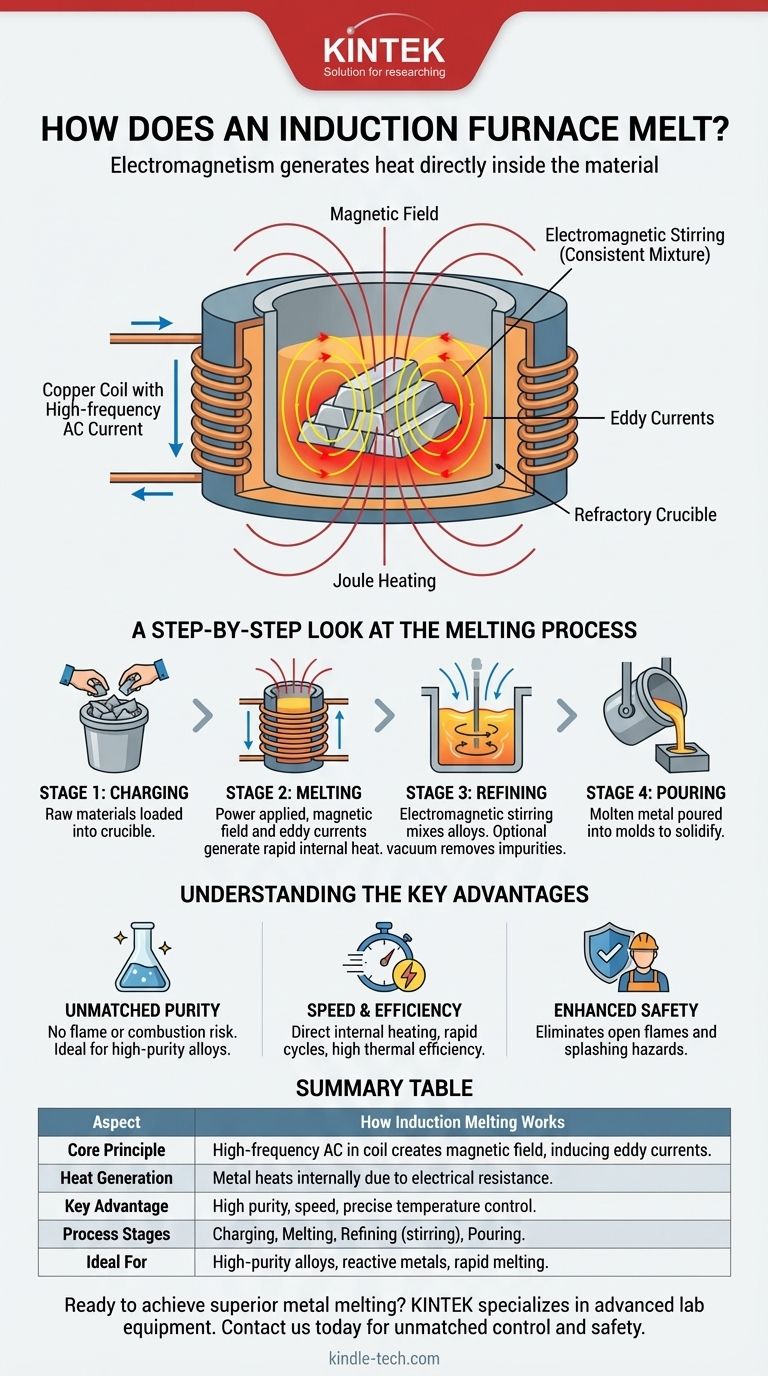

At its core, an induction furnace melts metal without any flame or external heating element. It uses the principles of electromagnetism to generate intense heat directly inside the material itself. A high-frequency alternating current flows through a copper coil, creating a powerful magnetic field that induces electrical "eddy" currents within the metal charge, causing it to heat up rapidly and liquefy due to its own electrical resistance.

The fundamental advantage of induction melting is its precision and purity. By converting electrical energy directly into heat within the target material, it offers a faster, cleaner, and more controllable process than methods relying on external combustion or electric arcs.

The Core Principle: Electromagnetic Induction

An induction furnace operates on the same fundamental physics that powers wireless chargers, but on a massively more powerful scale. The process transforms electrical energy into thermal energy in two key steps.

From Electricity to a Magnetic Field

The system starts with a specialized power supply that converts standard, low-frequency alternating current (AC) into a medium or high-frequency AC. This current is then directed through a water-cooled copper induction coil that lines the furnace's crucible. As the powerful AC flows through this coil, it generates a strong and rapidly reversing magnetic field in the center of the furnace.

Generating Heat with Eddy Currents

This magnetic field penetrates the metal (the "charge") placed inside the crucible. According to Faraday's law of induction, the fluctuating magnetic field induces circular electrical currents within the metal. These are known as eddy currents.

The metal has a natural resistance to the flow of this electricity. This resistance causes immense friction on an atomic level, generating tremendous heat—a principle known as Joule heating. This internal heat generation is what causes the metal to quickly reach its melting point and liquefy, all without direct contact from any heating source.

The Inherent Stirring Effect

A key secondary benefit of this process is a natural electromagnetic stirring of the molten bath. The forces created by the magnetic field and eddy currents cause the liquid metal to circulate, ensuring a consistent temperature and a homogenous mixture of alloys without the need for mechanical stirring.

A Step-by-Step Look at the Melting Process

While the physics are complex, the operational process is straightforward and can be broken down into four distinct stages.

Stage 1: Charging

This is the preparation phase. The raw materials—scrap metal, ingots, or alloying elements—are selected and loaded into the crucible, which is the refractory-lined container sitting inside the induction coil.

Stage 2: Melting

Power is applied to the induction coil. The magnetic field is generated, eddy currents form, and the charge begins to heat from the inside out. The process is remarkably fast, and operators can precisely control the power input to manage the rate of melting.

Stage 3: Refining

Once the metal is liquid, the refining stage begins. The electromagnetic stirring helps mix in any added alloys evenly. In advanced systems like vacuum induction furnaces, this stage is critical for removing dissolved gases and impurities, allowing for the production of extremely high-purity superalloys and reactive metals. Samples can be taken and the composition adjusted without breaking the furnace's vacuum.

Stage 4: Pouring

After the molten metal reaches the desired temperature and chemical composition, the entire furnace assembly is tilted. The liquid metal is poured out of a spout in the crucible and into molds, where it cools and solidifies into its final shape, such as ingots.

Understanding the Trade-offs and Key Advantages

No technology is perfect for every application. Understanding the strengths of induction melting clarifies why it is chosen for specific tasks.

Advantage: Unmatched Purity and Control

Because there is no electric arc, flame, or combustion process, there is no risk of contaminating the melt with carbon or unwanted gases. This makes induction melting the superior method for producing clean steel, high-performance alloys, and materials where precise chemistry is non-negotiable.

Advantage: Speed and Energy Efficiency

Heat is generated directly within the material, not transferred from an external source. This results in very rapid heating cycles and higher thermal efficiency, as less energy is wasted heating the furnace structure or surrounding air.

Advantage: Enhanced Safety

Modern induction furnaces eliminate the hazards of open flames and the splashing associated with older smelting methods. The primary heat is contained entirely within the charge, creating a safer operational environment.

Consideration: The Power Supply

The primary requirement for an induction furnace is a sophisticated power supply capable of converting mains frequency to the necessary medium or high frequency. This represents a significant component of the system's cost and complexity but is essential for its operation.

Making the Right Choice for Your Goal

The decision to use an induction furnace is driven by the final requirements of the material being produced.

- If your primary focus is high-purity alloys or reactive metals: A vacuum induction furnace is the ideal choice for its clean, highly controlled environment that prevents contamination.

- If your primary focus is rapid melting and process efficiency: The direct internal heating of induction offers significant speed advantages and better energy utilization compared to traditional furnaces.

- If your primary focus is improved workplace safety and environmental standards: Induction furnaces provide a cleaner, quieter, and safer melting operation by eliminating combustion byproducts and open flames.

Ultimately, the induction furnace leverages fundamental physics to provide a level of control over material transformation that is simply unattainable with older technologies.

Summary Table:

| Aspect | How Induction Melting Works |

|---|---|

| Core Principle | Uses a high-frequency AC current in a copper coil to create a magnetic field, inducing eddy currents in the metal. |

| Heat Generation | Metal heats internally due to electrical resistance (Joule heating), melting from the inside out. |

| Key Advantage | No flame or external heating element; ensures high purity, speed, and precise temperature control. |

| Process Stages | Charging → Melting → Refining (with stirring) → Pouring. |

| Ideal For | High-purity alloys, reactive metals, and applications requiring rapid, contamination-free melting. |

Ready to achieve superior metal melting with precision and purity? KINTEK specializes in advanced lab equipment, including induction furnaces designed for high-performance applications. Whether you're working with reactive metals, high-purity alloys, or need rapid, energy-efficient melting, our solutions deliver unmatched control and safety. Contact us today to learn how KINTEK can enhance your laboratory's capabilities and meet your specific melting needs!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the hardest metal to melt? Tungsten Leads, But Advanced Materials Go Further

- Will an induction heater heat brass? A Guide to Efficient Non-Ferrous Metal Heating

- What are induction coils used for? Precision Heating for Metal Hardening, Brazing & Forging

- Which metals can be heated using induction? Discover the best metals for efficient induction heating.

- What is the frequency range of an induction furnace? Unlock the Key to Efficient Metal Melting

- What is the primary function of an induction furnace in Al-Fe-Ni alloy melting? Achieve Unmatched Chemical Homogeneity

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What does an induction coil do? Harnessing Electromagnetic Power for Heating and Voltage