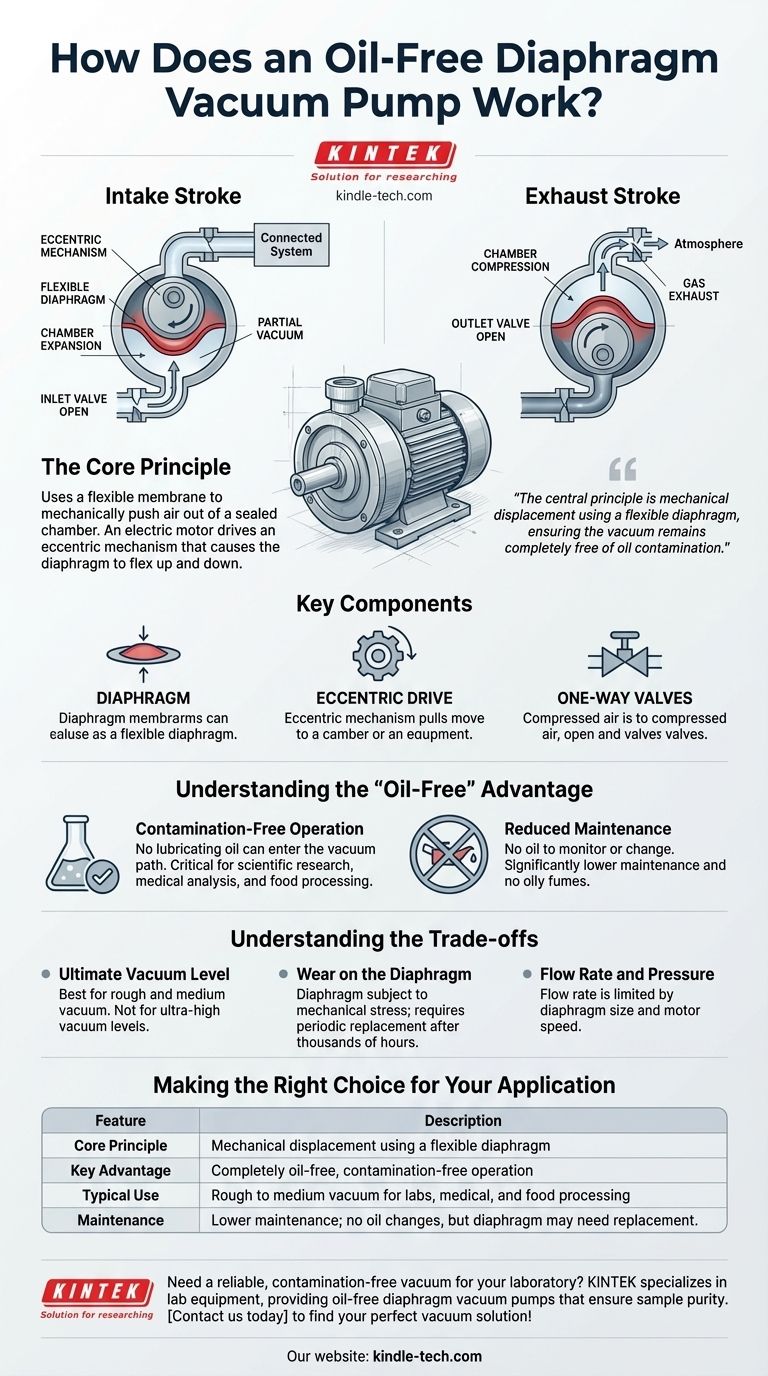

At its core, an oil-free diaphragm vacuum pump works by using a flexible membrane to mechanically push air out of a sealed chamber. An electric motor drives an eccentric mechanism that causes the diaphragm to repeatedly flex up and down, alternately drawing air in through an inlet valve and expelling it through an outlet valve, creating a vacuum without any oil.

The central principle is mechanical displacement using a flexible diaphragm. This design intentionally isolates the pump's mechanical moving parts from the gas path, ensuring the vacuum remains completely free of oil contamination.

How a Diaphragm Pump Creates a Vacuum

The operation is elegant in its simplicity, relying on a few key components working in a precise cycle. Think of it as a mechanical lung that breathes air out of a system.

The Key Components

The pump head contains three critical parts: a flexible diaphragm, an eccentric drive, and a set of one-way valves.

The diaphragm is a durable, flexible membrane that separates the drive mechanism from the pumping chamber. The eccentric, connected to a motor, converts rotational motion into an up-and-down or back-and-forth movement for the diaphragm.

The Pumping Cycle: Intake Stroke

When the motor's eccentric pulls the diaphragm down or back, the volume of the chamber above it increases. This expansion creates a partial vacuum—a zone of lower pressure—inside the chamber.

This pressure drop causes the inlet valve to open, allowing gas molecules from the connected system or vessel to be drawn into the pump chamber. The outlet valve remains closed.

The Pumping Cycle: Exhaust Stroke

As the eccentric continues its rotation, it pushes the diaphragm up or forward. This action compresses the gas that was just drawn into the chamber.

The rising pressure forces the inlet valve to shut and the outlet valve to open, expelling the compressed gas into the atmosphere. This cycle repeats rapidly, progressively removing more air from the system to deepen the vacuum.

Understanding the "Oil-Free" Advantage

The term "oil-free" is the most significant feature of this technology and the primary reason for its selection in many sensitive applications.

Contamination-Free Operation

Because the drive mechanism is physically separated from the pumping chamber by the diaphragm, no lubricating oil can enter the vacuum path.

This is non-negotiable for applications in scientific research, medical analysis, and food processing, where even trace amounts of oil vapor would contaminate samples and invalidate results.

Reduced Maintenance

With no oil to monitor, change, or dispose of, diaphragm pumps offer significantly lower maintenance requirements compared to oil-sealed pumps.

This also eliminates the release of oily fumes into the laboratory or production environment, contributing to cleaner air and a safer workspace.

Understanding the Trade-offs

While highly effective, diaphragm pumps are not the solution for every vacuum application. Understanding their limitations is crucial for proper selection.

Ultimate Vacuum Level

Diaphragm pumps are masters of the rough and medium vacuum range. They are not designed to achieve the ultra-high vacuum levels required for applications like particle accelerators or semiconductor manufacturing. For those needs, technologies like turbomolecular or ion pumps are necessary.

Wear on the Diaphragm

The diaphragm is a robust component, but it is subject to mechanical stress and will eventually wear out. Diaphragm replacement is a standard maintenance procedure after thousands of hours of operation, and its lifespan is a key performance metric.

Flow Rate and Pressure

The flow rate (how quickly the pump removes gas) is directly related to the size of the diaphragm and the speed of the motor. Achieving very high flow rates may require larger, more complex multi-stage diaphragm pumps.

Making the Right Choice for Your Application

Selecting the correct vacuum technology depends entirely on your end goal.

- If your primary focus is a clean, contaminant-free vacuum for a lab, medical device, or analytical instrument: An oil-free diaphragm pump is the industry standard and the ideal choice.

- If your primary focus is removing bulk air quickly on a tight budget: A traditional oil-sealed rotary vane pump may be faster, but you must accept the risk and maintenance burden of oil contamination.

- If your primary focus is achieving the deepest possible vacuum (ultra-high vacuum): Your application requires a more advanced technology, and a diaphragm pump will often be used as a preliminary "roughing" pump for the more powerful system.

Ultimately, understanding the simple, reliable mechanism of the diaphragm pump empowers you to choose the right tool for a clean and efficient vacuum.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Mechanical displacement using a flexible diaphragm. |

| Key Advantage | Completely oil-free, contamination-free operation. |

| Typical Use | Rough to medium vacuum for labs, medical, and food processing. |

| Maintenance | Lower maintenance; no oil changes, but diaphragm may need replacement. |

Need a reliable, contamination-free vacuum for your laboratory?

KINTEK specializes in lab equipment and consumables, providing oil-free diaphragm vacuum pumps that ensure the purity of your samples and the integrity of your results. Our pumps are designed for applications where even trace oil contamination is unacceptable.

Contact us today to find the perfect vacuum solution for your sensitive work!

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why use zirconia grinding balls for LLZTO? Protect Purity and Ionic Conductivity

- Why select tungsten carbide grinding balls for chromium & silicon? Maximize Milling Power and Purity

- What is the purpose of using quartz wool as a support material in adsorption bed layers? Enhance Stability & Flow

- What are the overall advantages of using vacuum pumps? Achieve Unmatched Process Control & Efficiency

- Why are high-temperature resistant springs used for Tantalum wire in HFCVD? Achieve Precise Diamond Film Uniformity

- Why are airtight ball mill jars required for argyrodite solid-state electrolytes? Ensuring Safety and Purity

- What is the role of a gas purification unit in the SHS process? Ensure Pristine Metal Dispersion & Film Stability

- What does a quartz tube do? Create a Pure, High-Temp Environment for Critical Processes