In short, lower temperatures are the primary driver for deposition. This physical process, where a substance transitions directly from a gas to a solid without passing through a liquid phase, is fundamentally an energy-shedding event. For gas molecules to lock themselves into a rigid crystal structure, they must release their kinetic energy, and a cold environment or surface provides the necessary conditions for this to happen.

Deposition is a direct consequence of creating a supersaturated gas, a condition achieved when the temperature drops low enough for gas molecules to lose their energy and lock into a solid structure. The colder the surface, the more readily this transformation occurs.

The Fundamental Role of Molecular Energy

To understand deposition, we must first consider what temperature truly represents at the molecular level. It is a measure of the average kinetic energy—or motion—of molecules.

How Temperature Governs Molecular Motion

In a gas, molecules possess high kinetic energy. They move rapidly and randomly, bouncing off each other without sticking together.

As temperature decreases, this kinetic energy is removed. The molecules slow down significantly.

Reaching a State of Stability

Forming a solid is an exothermic process, meaning it releases energy. A solid is a lower-energy, more stable state than a gas.

For fast-moving gas molecules to settle into this stable, solid structure, they must shed their excess kinetic energy as heat. A cold environment or surface acts as an energy sink, making it easy for molecules to release this energy and "stick" to the surface and each other.

The Science of Supersaturation

While low temperature is the catalyst, the specific mechanism that triggers deposition is called supersaturation. This occurs when a volume of space holds more vapor of a substance than it theoretically can at that temperature.

The Concept of Saturation

Think of air as a sponge. At a given temperature, it can "hold" a specific maximum amount of water vapor. When it holds this maximum amount, it is considered saturated.

Warm air can hold significantly more water vapor than cold air. Its saturation point is much higher.

How Cooling Creates Supersaturation

When a parcel of gas is cooled, its ability to hold vapor decreases dramatically. However, the actual amount of vapor in the gas hasn't changed yet.

This creates a state of supersaturation, where the gas is holding far more vapor than it should be able to at its new, lower temperature. The system is now unstable and must shed the excess vapor.

The Critical Role of a Cold Surface

This is where deposition happens. When this supersaturated gas comes into contact with a surface that is below its "frost point" or deposition temperature, the molecules that strike the surface lose their energy almost instantly.

They do not have enough energy to remain as a gas or even become a liquid; instead, they lock directly into a solid crystal lattice. This is precisely how frost forms on a cold window pane overnight.

Understanding the Key Variables

Temperature is the primary driver, but it doesn't act in isolation. A complete understanding requires acknowledging other critical factors that influence the process.

The Influence of Pressure

Deposition is a function of both temperature and pressure. On a substance's phase diagram, deposition occurs at pressures and temperatures below the triple point—the unique point where solid, liquid, and gas phases can coexist. Changing the pressure can change the temperature at which deposition will occur.

The Rate of Deposition

While a lower temperature is necessary for deposition to occur, the rate at which it happens also depends on factors like the concentration of the vapor and the flow of the gas. A higher concentration of the substance in the gas phase can lead to a faster deposition rate, assuming the temperature conditions are met.

The Nature of the Substrate

The surface onto which the material deposits is called the substrate. Its characteristics, such as texture and material composition, can influence how easily the first crystals (nucleation sites) form, which in turn affects the structure and quality of the final solid layer.

Making the Right Choice for Your Goal

Understanding this relationship allows you to control or predict the process based on your objective.

- If your primary focus is to promote deposition (e.g., thin-film manufacturing, freeze-drying): The goal is to create a significant temperature difference by introducing a surface that is substantially colder than the surrounding gas.

- If your primary focus is to prevent deposition (e.g., stopping frost on equipment or aircraft wings): The strategy is to ensure that critical surface temperatures remain above the frost point of the ambient air.

- If you are analyzing a natural phenomenon (e.g., snow formation in clouds): Remember that deposition is a system-level event, driven by the dynamic interplay between falling temperatures, pressure changes, and the concentration of water vapor.

Ultimately, temperature is the most powerful and direct lever for controlling the deposition process.

Summary Table:

| Factor | Effect on Deposition |

|---|---|

| Temperature | Lower temperatures increase deposition by reducing molecular energy. |

| Pressure | Influences the deposition temperature threshold (occurs below the triple point). |

| Vapor Concentration | Higher concentration can accelerate the deposition rate. |

| Substrate Surface | Affects nucleation and the quality of the deposited solid layer. |

Ready to Control Your Deposition Process with Precision?

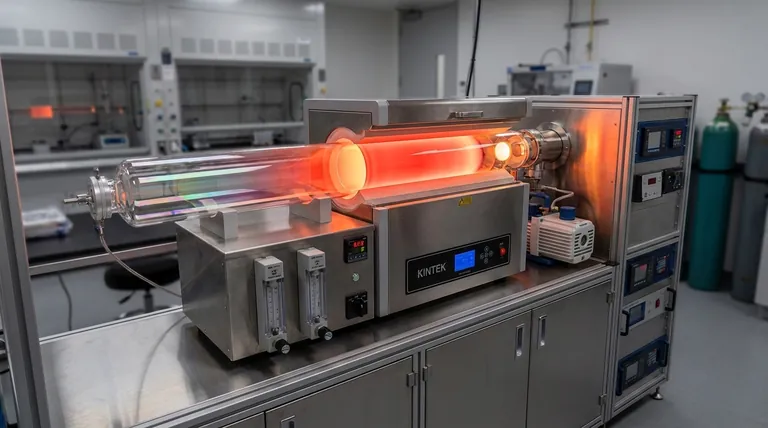

KINTEK specializes in advanced lab equipment, including temperature-controlled systems designed for precise thin-film deposition and material synthesis. Whether you're in research or manufacturing, our solutions ensure optimal conditions for gas-to-solid transformations.

Contact us today using the form below to discuss how we can enhance your laboratory's capabilities.

#ContactForm

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the process of vapor deposition? A Guide to CVD and PVD Thin-Film Coating

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is the epitaxy method of graphene? A Guide to High-Quality, Large-Area Growth

- Do all CVD diamonds have post growth treatment? Uncovering the Industry Standard for Gem Quality

- What advantages does CVD equipment offer for depositing Pt on TiO2? Atomic Precision for Superior Performance

- What is the method of deposition of thin films? Choose the Right PVD or CVD Technique for Your Lab

- What is chemical vapor deposition process for thin film? The Ultimate Guide to High-Performance Coatings

- What is the Chemical Vapour Deposition (CVD) method for growing diamonds? Discover Precision Carbon Synthesis