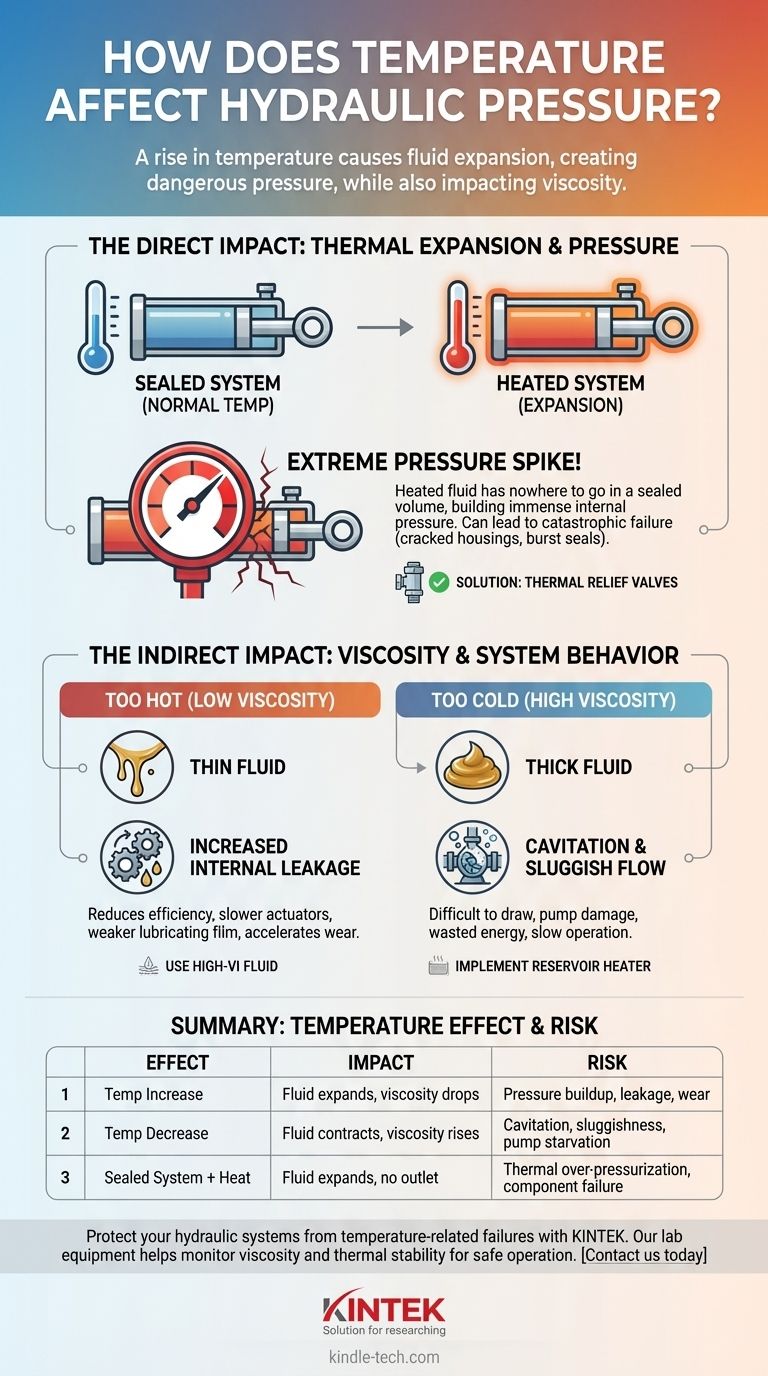

In short, a rise in temperature causes hydraulic fluid to expand, which can create a significant and potentially dangerous increase in pressure within a sealed part of a system. This direct effect is a result of thermal expansion, where the heated fluid has nowhere to go, forcing pressure to build.

Temperature affects hydraulic systems in two critical ways. First, it directly changes pressure in a sealed volume through thermal expansion. Second, and more commonly, it indirectly impacts system performance by altering the fluid's viscosity, which affects flow, efficiency, and component wear.

The Direct Impact: Thermal Expansion and Pressure

The most direct relationship between temperature and pressure in a hydraulic system is governed by the laws of physics. It is simple, powerful, and a critical safety consideration.

How Heat Creates Pressure in a Sealed System

Hydraulic fluid, like most liquids, expands when it gets hotter and contracts when it gets colder. In an open container, this is unnoticeable.

However, a hydraulic circuit can often be a closed, sealed volume. Consider a hydraulic cylinder where both ports are blocked, trapping the fluid inside.

If the ambient temperature rises—for example, if the machine is left in the sun—the trapped fluid will try to expand. Since it has no room to expand into, it will instead build immense internal pressure.

The Force of Thermal Expansion

The pressure increase from thermal expansion can be extreme, easily exceeding the system's normal operating pressure.

This phenomenon is responsible for a surprising number of component failures, such as cracked cylinder housings, burst seals, or damaged valves in equipment that is powered off.

Practical Example: A Cylinder in the Sun

Imagine a piece of construction equipment with a hydraulic arm parked overnight. As the sun heats the machine the next morning, the fluid trapped in the cylinders and lines expands.

Without a path to the reservoir, the pressure can rise high enough to permanently damage seals or even fracture a component, all while the machine is completely shut down. This is why thermal relief valves are a crucial safety feature.

The Indirect Impact: How Viscosity Changes System Behavior

More frequently, temperature affects a hydraulic system's behavior by changing the fluid's viscosity—its resistance to flow. This has profound effects on performance and efficiency.

When Fluid Gets Too Hot (Low Viscosity)

As hydraulic fluid heats up, its viscosity drops, and it becomes "thinner." This creates several problems.

It increases internal leakage within components like pumps, motors, and valves. This leakage reduces efficiency, meaning actuators move slower and the system struggles to build and hold pressure under load.

Thinner oil also provides a weaker lubricating film between moving parts, accelerating wear and reducing the operational life of expensive components.

When Fluid Gets Too Cold (High Viscosity)

When the fluid is cold, its viscosity is high, and it becomes "thicker." This is a common issue during cold-weather start-ups.

Thick oil is difficult for the pump to draw from the reservoir, which can lead to a condition called cavitation—the formation and collapse of vapor bubbles that can severely damage a pump in minutes.

High viscosity also increases flow resistance throughout the system, leading to sluggish operation, wasted energy (which turns into unwanted heat), and higher stress on the pump.

The Role of the Viscosity Index (VI)

Hydraulic fluids are rated with a Viscosity Index (VI). A fluid with a higher VI will maintain a more stable viscosity across a wider range of temperatures.

Using a high-VI fluid helps mitigate the negative effects of both hot and cold operation, making system performance more predictable and reliable.

Understanding the Trade-offs and Risks

Ignoring fluid temperature is not an option. It introduces risks to safety, performance, and equipment longevity.

The Danger of Thermal Over-Pressurization

The primary risk is catastrophic failure. A hose that bursts or a cylinder that cracks due to thermal expansion can release high-pressure fluid, creating a serious safety hazard. This risk is highest in systems without proper thermal relief protection.

The Hidden Costs of High Viscosity

Operating with fluid that is too thick is incredibly inefficient. The prime mover (engine or electric motor) must work much harder just to move the fluid, wasting fuel or electricity. The bigger risk, however, is starving the pump, which can lead to premature and costly failure.

The Performance Loss from Low Viscosity

Operating with fluid that is too hot directly translates to poor performance. Cycle times become longer, and the machine may be unable to lift its rated load. This loss of efficiency generates even more heat, creating a vicious cycle of rising temperatures and falling performance.

How to Apply This to Your System

Managing temperature is about ensuring stability. Your strategy will depend on your operating environment and system demands.

- If your primary focus is safety: Ensure the system is protected with correctly installed and set thermal relief valves, especially on any circuit that can trap fluid.

- If your primary focus is performance in hot environments: Invest in an adequately sized heat exchanger (oil cooler) and use a high-VI fluid to maintain optimal viscosity and efficiency.

- If your primary focus is reliability in cold climates: Implement a reservoir heater and a proper warm-up procedure to bring the fluid to its minimum operating temperature before placing the system under load.

Ultimately, controlling fluid temperature is fundamental to controlling the reliability, safety, and performance of any hydraulic system.

Summary Table:

| Temperature Effect | Impact on Hydraulic System | Resulting Risk |

|---|---|---|

| Temperature Increase | Fluid expands, viscosity drops | Pressure buildup, internal leakage, reduced lubrication |

| Temperature Decrease | Fluid contracts, viscosity rises | Cavitation, sluggish operation, pump starvation |

| Sealed System with Heat | Fluid expands with no outlet | Thermal over-pressurization, component failure |

Protect your hydraulic systems from temperature-related failures with KINTEK. Our lab equipment and consumables help you monitor fluid viscosity, test thermal stability, and ensure your hydraulic components operate safely and efficiently. Whether you're in construction, manufacturing, or heavy equipment maintenance, KINTEK provides the tools you need to prevent pressure spikes and extend component life. Contact us today to discuss your specific hydraulic testing and monitoring needs!

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

People Also Ask

- How does a high-efficiency stirring system address the technical challenges of solvent viscosity? Master Pretreatment.

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- How does a laboratory stirrer influence MOF product quality? Master Precision in Non-Solvothermal Synthesis

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- What role does high-speed stirring equipment play in fungal pre-cultures? Optimize Your Solid-State Fermentation