In the pharmaceutical industry, mixers are not a single class of equipment but a diverse range of specialized tools, each designed for a specific purpose. They are broadly categorized based on the physical state of the materials being mixed—solids, liquids, or semi-solids—and the physical mechanism they use, such as tumbling, convection, or high-shear force. The selection depends entirely on the ingredients' properties and the desired characteristics of the final product.

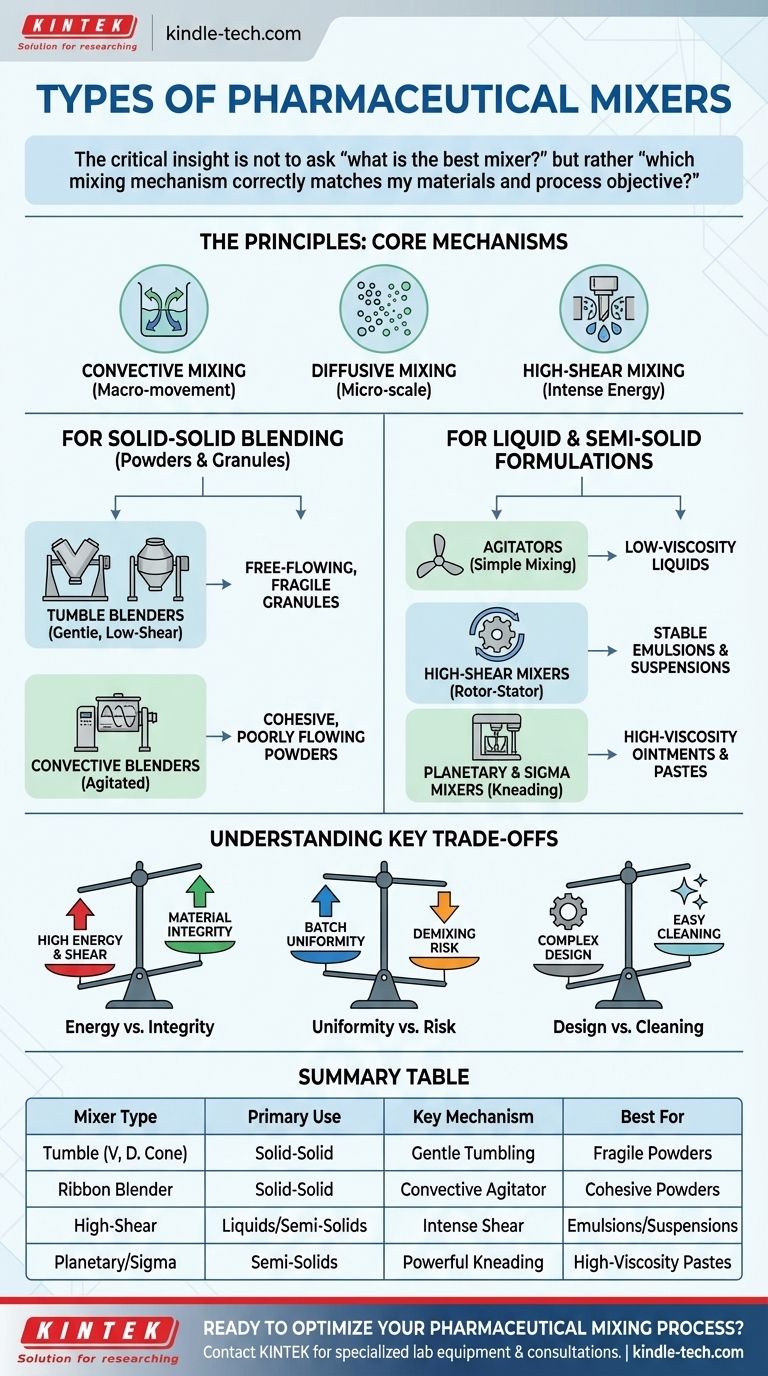

The most critical insight is not to ask "what is the best mixer?" but rather "which mixing mechanism correctly matches my materials and process objective?" The choice between a gentle tumble blender for fragile granules and a high-shear mixer for a stable emulsion is fundamental to achieving product quality and efficacy.

The Principles: How Pharmaceutical Mixers Work

Before comparing specific models, it is essential to understand the core mechanisms that drive the mixing process. The effectiveness of any mixer is determined by its ability to employ one or more of these principles.

Convective Mixing

This is the macro-movement of large groups of particles from one location to another within the mixer. It is achieved by paddles, blades, or the rotation of the entire vessel, leading to rapid bulk blending.

Diffusive Mixing

Also known as shear mixing, this occurs at a smaller scale. It involves the movement of individual particles over one another, which is crucial for achieving a high degree of uniformity, especially in powder blends.

High-Shear Mixing

This mechanism involves intense mechanical energy to break down particles, droplets, or agglomerates. A rotor moving at high speed within a stationary stator creates hydraulic shear, which is essential for creating stable emulsions, suspensions, and fine dispersions.

Common Types of Pharmaceutical Mixers

Mixers are best understood by grouping them according to the type of formulation they are designed to produce.

For Solid-Solid Blending (Powders and Granules)

These are used for creating uniform mixtures of dry powders, which is a foundational step for manufacturing tablets and capsules.

-

Tumble Blenders: These mixers have a stationary drive that rotates the entire vessel, causing the material to cascade and intermix. They are known for low-shear, gentle blending, making them ideal for free-flowing, dense, or fragile granules.

- V-Blender: Consists of two joined cylinders. As it rotates, the batch is repeatedly split and combined, promoting diffusive mixing.

- Double Cone Blender: A simple design that is easy to clean and offers gentle mixing as material flows from one cone to the other.

- Octagonal Blender: As its name implies, its octagonal shape provides more surfaces than a V-blender, allowing it to handle larger volumes of material in a smaller physical footprint.

-

Convective Blenders (Agitator Blenders): These mixers have a stationary shell and a moving internal agitator (like a ribbon or paddle) that moves the material. They are more effective than tumble blenders for cohesive or poorly flowing powders.

- Ribbon Blender: A horizontal U-shaped trough contains a double helical ribbon that moves material both radially and laterally. It is highly efficient for powder blending.

For Liquid and Semi-Solid Formulations

These mixers are designed to handle everything from low-viscosity solutions to high-viscosity ointments and pastes.

-

Agitators: These are the most common type for liquid-liquid mixing or dissolving solids into liquids. Simple propellers or turbines are mounted on a shaft within a tank to create a vortex and ensure bulk movement.

-

High-Shear Mixers (Rotor-Stator): Essential for creating emulsions and suspensions. A high-speed rotor generates intense mechanical and hydraulic shear, breaking down droplets and particles to create a stable, homogenous mixture.

-

Planetary & Sigma Blade Mixers: Used for the most challenging applications: high-viscosity semi-solids like ointments, creams, and wet granulations. Powerful blades move through the material with a planetary motion or in a "sigma" shape to knead and fold the thick mass, ensuring complete dispersion.

Understanding the Key Trade-offs

Selecting a mixer involves balancing efficiency, product quality, and operational constraints. No single design is superior in all aspects.

Mixing Energy vs. Material Integrity

High-shear mixers are fast and effective for homogenization but can generate significant heat and damage fragile or heat-sensitive active pharmaceutical ingredients (APIs). Tumble blenders are extremely gentle but may be ineffective for cohesive powders or require longer mixing times.

Batch Uniformity vs. Demixing Risk

While convective blenders (like Ribbon Blenders) are fast, they can create shear that causes segregation (demixing) of particles with different sizes or densities. Tumble blenders often provide a more uniform final blend for these types of materials, though they may take longer.

Ease of Cleaning and Validation

Simpler designs with smooth surfaces, like Double Cone and V-blenders, are far easier to clean and validate. This is a critical consideration in pharmaceutical manufacturing to prevent cross-contamination. Complex agitators in Ribbon or Planetary mixers have more contact parts and can be challenging to clean thoroughly.

Making the Right Choice for Your Application

Your final decision must be guided by the specific goals of your formulation process.

- If your primary focus is gentle blending of free-flowing, friable powders: A Tumble Blender (V-Blender, Double Cone) is the standard choice to ensure uniformity without particle damage.

- If your primary focus is creating a stable, fine-droplet emulsion or suspension: A High-Shear Rotor-Stator Mixer is non-negotiable to achieve the required particle size reduction.

- If your primary focus is mixing highly viscous pastes, ointments, or wet masses: A Planetary or Sigma Blade Mixer is necessary to provide the powerful kneading action required.

- If your primary focus is blending powders that are cohesive or have poor flow: A Ribbon Blender provides the necessary forced movement to ensure a homogenous mixture.

Ultimately, successful pharmaceutical manufacturing hinges on selecting the equipment that applies the right physical forces to your specific materials.

Summary Table:

| Mixer Type | Primary Use | Key Mechanism | Best For |

|---|---|---|---|

| Tumble Blenders (V, Double Cone) | Solid-Solid Blending | Gentle tumbling, diffusive mixing | Free-flowing, fragile powders & granules |

| Ribbon Blender | Solid-Solid Blending | Convective mixing with an agitator | Cohesive or poorly flowing powders |

| High-Shear Mixer | Liquids & Semi-Solids | Intense rotor-stator shear | Creating stable emulsions & suspensions |

| Planetary/Sigma Mixer | Semi-Solids | Powerful kneading & folding action | High-viscosity creams, ointments, pastes |

Ready to Optimize Your Pharmaceutical Mixing Process?

Choosing the correct mixer is critical to your product's quality, efficacy, and compliance. The experts at KINTEK are here to help you navigate these essential decisions.

We provide specialized lab equipment and consumables to meet your precise pharmaceutical needs. Whether you are developing a new solid dosage form, a stable emulsion, or a high-viscosity cream, we can connect you with the ideal mixing technology for your application.

Let us help you achieve perfect homogeneity and scale-up success.

Contact KINTEK today for a personalized consultation and discover how our solutions can enhance your laboratory's efficiency and output.

Visual Guide

Related Products

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the necessity of using an industrial-grade high-shear homogenizer for biomass washing? Ensure Process Efficiency

- What function do magnetic stirrers and high-shear homogenizers serve? Optimize Core-Shell PCM Synthesis

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation

- Why are high-shear mixing or ultrasonic homogenizers necessary for MMT nanocomposites? Unlock True Nano-Reinforcement

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?