In modern industry, additive manufacturing is no longer just a tool for novelty prototypes. It has become a critical production technology used to create lightweight aerospace components, patient-specific medical implants, and highly complex tooling. By building objects layer-by-layer directly from a digital file, industries are fundamentally rethinking how parts are designed, tested, and manufactured at scale.

The core value of additive manufacturing (AM) in an industrial context is not simply 3D printing an object. It is the ability to unlock geometric complexity, enabling the creation of parts that are stronger, lighter, and more functional than what is possible with traditional manufacturing methods.

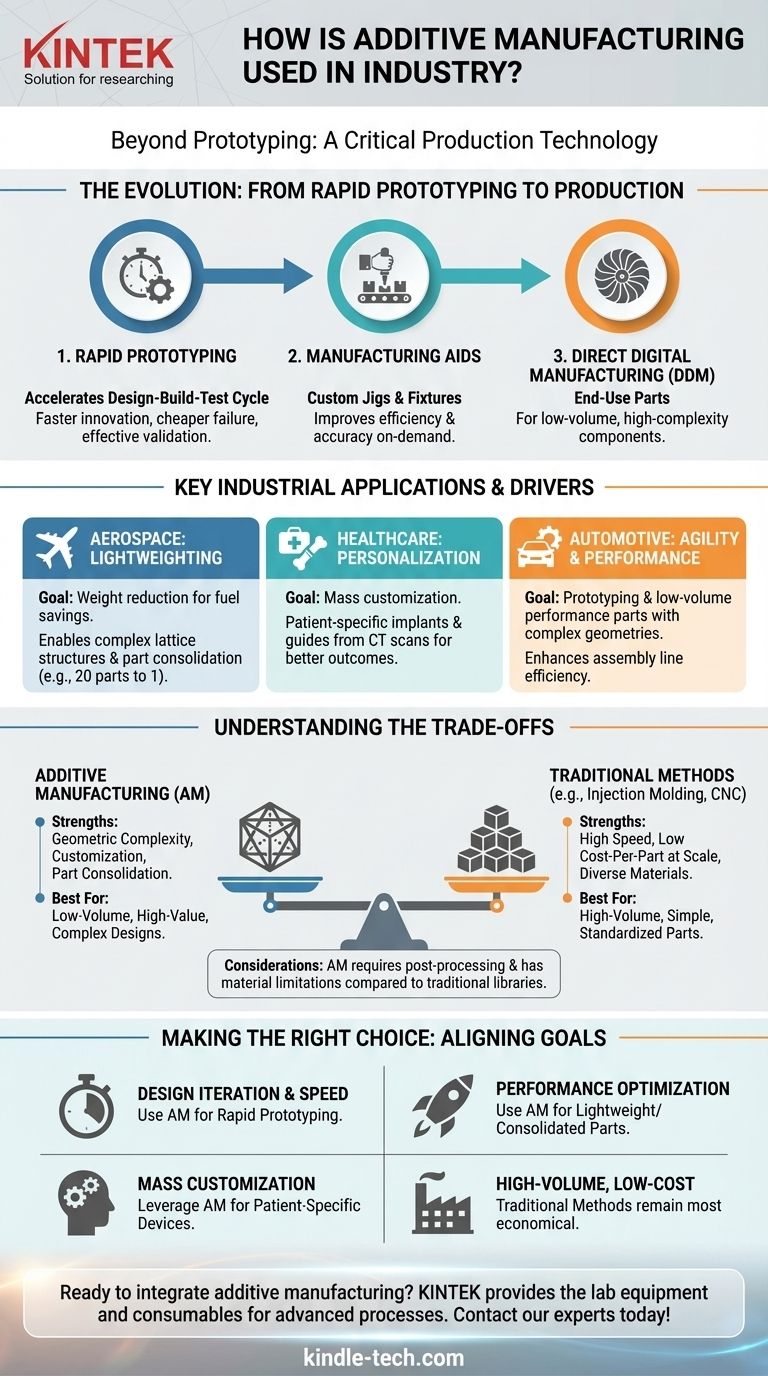

From Rapid Prototyping to Production

Additive manufacturing, often called 3D printing, began its industrial journey in one key area but has since evolved into a full-scale production method.

The Foundation: Rapid Prototyping

Initially, the primary use of AM was rapid prototyping. It gave engineers the power to hold a physical version of their digital design in hours instead of weeks.

This dramatically accelerates the design-build-test cycle. It allows for faster innovation, cheaper failure, and more effective product validation before committing to expensive mass-production tooling.

The Evolution: Manufacturing Aids

A major, high-value application for AM is the creation of jigs, fixtures, and other manufacturing aids. These are custom tools used on an assembly line to hold a part in place for machining, inspection, or assembly.

Traditionally, creating these tools was slow and expensive. With AM, a factory can print a custom, lightweight, and ergonomic fixture on-demand, directly improving the efficiency and accuracy of its existing manufacturing processes.

The Goal: Direct Digital Manufacturing (DDM)

The ultimate goal, now a reality in many sectors, is Direct Digital Manufacturing (DDM). This involves using AM to produce the final, end-use parts that go into a product.

DDM is most valuable for low-volume production runs, highly customized parts, or components whose complex designs provide a significant performance advantage.

Key Industrial Applications and Their Drivers

Different industries leverage AM to solve very different core problems. The technology's flexibility is its greatest strength.

Aerospace: The Pursuit of Lightweighting

The aerospace industry uses metal AM processes like sintering to achieve one primary goal: weight reduction. In an aircraft, every kilogram saved translates to significant fuel savings and increased payload capacity over the vehicle's lifetime.

AM allows engineers to design parts with complex internal lattice structures that maintain strength while removing unnecessary mass. It also enables part consolidation, where an assembly of 20 different components can be redesigned and printed as a single, lighter, and more reliable part.

Healthcare: The Demand for Personalization

In medicine, "one size fits all" is rarely optimal. AM enables mass customization at an unprecedented scale, particularly for surgical implants and guides.

Doctors can use a patient's CT scan to design and print a knee implant, cranial plate, or dental crown that is a perfect match for their unique anatomy. This improves patient outcomes, reduces surgery time, and minimizes complications.

Automotive: Agility and Performance

The automotive industry uses AM across the entire product lifecycle. It is heavily used for prototyping new vehicle designs and components.

For performance and luxury vehicles, AM is used to produce low-volume, end-use parts with complex geometries that improve airflow or reduce weight. It is also essential for creating custom jigs and fixtures that make vehicle assembly lines more agile and efficient.

Understanding the Trade-offs

Additive manufacturing is a powerful tool, but it is not a universal replacement for traditional methods. Understanding its limitations is key to using it effectively.

The Challenge of Scale and Speed

For producing thousands of simple, identical parts, traditional methods like injection molding or CNC machining are still significantly faster and cheaper per part. AM struggles to compete on pure volume and speed for high-run production.

Material Properties and Post-Processing

While the range of AM materials is growing, it is still more limited than the vast library of metals and plastics available for traditional manufacturing.

Furthermore, many additively manufactured parts, especially metal ones, require post-processing steps like heat treatment, surface polishing, or machining to achieve the final desired properties and tolerances. These steps add time and cost to the process.

The Cost-per-Part Equation

The business case for AM rarely hinges on being the cheapest option for a simple part. The value must be derived from a performance gain that cannot be achieved otherwise.

This includes benefits like improved fuel efficiency from a lighter part, better patient outcomes from a custom implant, or faster product development from rapid prototyping.

Making the Right Choice for Your Goal

Applying additive manufacturing effectively requires aligning the technology's strengths with your specific industrial objective.

- If your primary focus is design iteration and speed-to-market: Use AM for rapid prototyping to validate form, fit, and function quickly.

- If your primary focus is performance optimization: Use AM to create lightweight or consolidated parts that are impossible with traditional methods, especially in aerospace or high-performance sectors.

- If your primary focus is mass customization: Leverage AM for patient-specific medical devices or low-volume custom products where personalization is the key value driver.

- If your primary focus is high-volume, low-cost production: Traditional manufacturing methods remain the most economical choice for simple, standardized parts.

Ultimately, additive manufacturing is a strategic capability that, when applied to the right problem, redefines what is possible in engineering and production.

Summary Table:

| Application | Industry | Key Driver |

|---|---|---|

| Lightweight Components | Aerospace | Weight Reduction & Fuel Efficiency |

| Patient-Specific Implants | Healthcare | Mass Customization & Improved Outcomes |

| Rapid Prototyping & Jigs | Automotive | Speed-to-Market & Assembly Efficiency |

| Direct Digital Manufacturing (DDM) | Multiple | Low-Volume, High-Complexity Production |

Ready to integrate additive manufacturing into your workflow? KINTEK specializes in providing the lab equipment and consumables needed for advanced manufacturing processes, from material testing to quality control. Whether you're in aerospace, medical, or automotive, our solutions help you achieve precision and efficiency. Contact our experts today to discuss how we can support your innovative projects!

Visual Guide

Related Products

- Assemble Lab Cylindrical Press Mold

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Three-dimensional electromagnetic sieving instrument

- Infrared Heating Quantitative Flat Plate Press Mold

People Also Ask

- What role does a high-strength stainless steel die play in sulfide battery molding? Key to High-Density Electrolytes

- What is the purpose of using a mold for pellet pressing when preparing catalyst test samples? Ensure Data Consistency

- What role do high-strength graphite molds play during vacuum hot pressing? Enhance Precision in CuAlMn Composites

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture