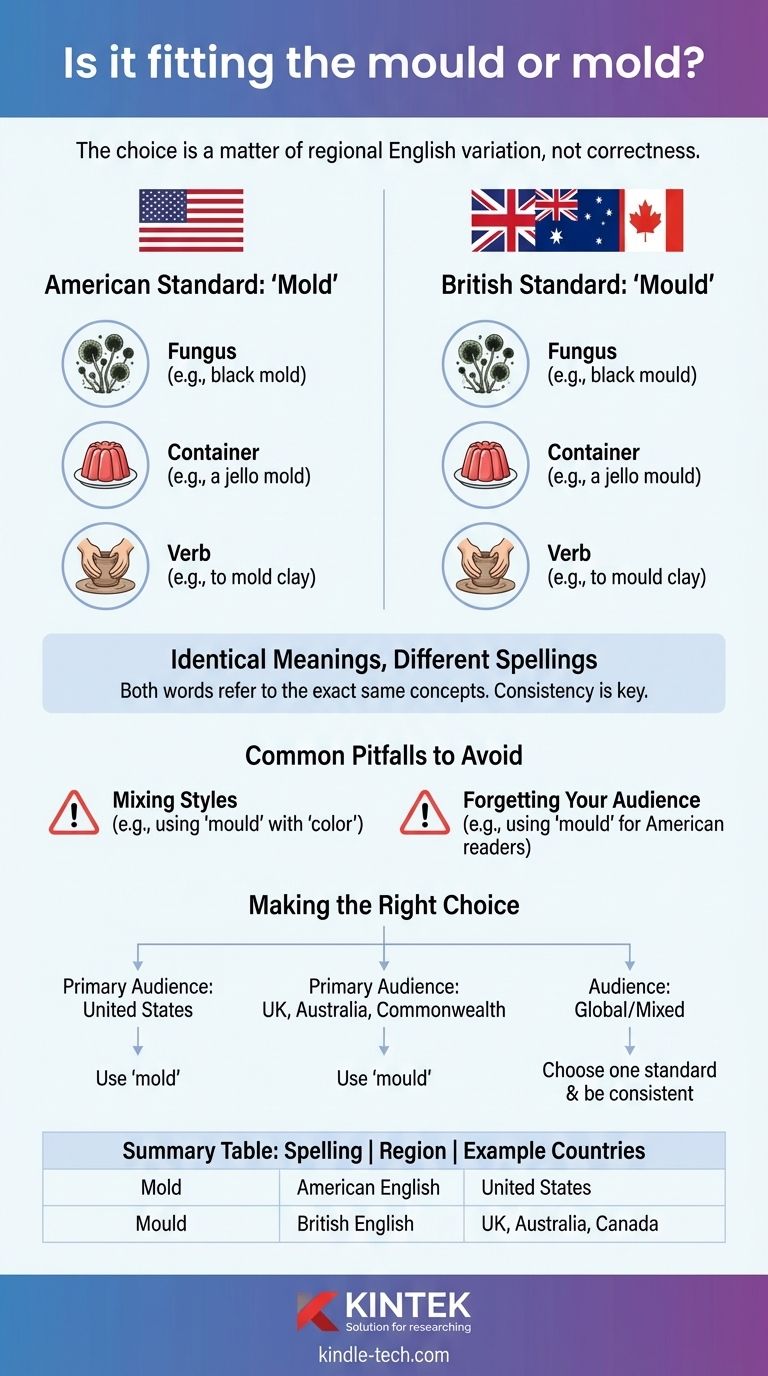

The choice between 'mould' and 'mold' is a simple matter of regional English variation. The correct spelling depends entirely on your intended audience. In American English, the standard spelling is mold, while in British English, it is mould.

The core issue isn't which spelling is "correct," but which is appropriate for your reader. Both words mean the exact same thing; the only difference is geographic convention. The key to professional writing is choosing one and maintaining consistency.

The Geographic Divide: American vs. British English

The difference between these two spellings is a clear example of the systematic variations between the two dominant forms of the English language.

The American Standard: 'Mold'

In the United States, mold is the only standard spelling. This applies to all definitions of the word.

This includes the fungus (black mold), the container used for shaping (a jello mold), and the verb meaning to shape (to mold the clay).

The British Standard: 'Mould'

Throughout the United Kingdom, Australia, New Zealand, and other Commonwealth countries that follow British convention, mould is the correct spelling.

Just like its American counterpart, this spelling is used for all the word's meanings, from the biological to the industrial.

Identical Meanings, Different Spellings

It is critical to understand that the meaning does not change with the spelling. Both words refer to the same concepts.

For example, "shaping the future" could be described as "molding the future" in an American publication or "moulding the future" in a British one. Both are correct in their respective contexts.

Common Pitfalls to Avoid

While the rule is simple, inconsistency can undermine the professionalism of your writing. The choice of 'mold' or 'mould' is part of a larger pattern of spelling differences.

The Risk of Mixing Styles

Using 'mould' (British) in the same document as 'color' (American) or 'organize' (American) creates a jarring and inconsistent experience for the reader.

This inconsistency can appear unprofessional and suggest a lack of attention to detail.

Forgetting Your Audience

The most common mistake is failing to consider the primary audience. Using 'mould' for a predominantly American readership can be just as distracting as using 'mold' for a British one.

Always tailor your language and spelling to the people you are trying to reach.

Making the Right Choice for Your Document

Your decision should be based on a clear and consistent editorial strategy.

- If your primary audience is in the United States: Always use 'mold' to maintain consistency with American English conventions.

- If your primary audience is in the UK, Australia, or another Commonwealth nation: Use 'mould' to align with standard British English.

- If your audience is global or mixed: Choose one standard (either American or British) and apply it consistently across your entire document for all relevant words (e.g., color/colour, center/centre).

By understanding this simple distinction, you ensure your writing is clear, consistent, and appropriate for your reader.

Summary Table:

| Spelling | Region | Example Countries |

|---|---|---|

| Mold | American English | United States |

| Mould | British English | UK, Australia, Canada |

Need help ensuring your technical documents are perfectly tailored for your target audience? At KINTEK, we understand the importance of precision and consistency in professional communication, just as we do in our high-quality lab equipment and consumables. Whether you're serving a local lab or a global research community, clarity is key. Contact us today to discuss how our solutions can support your laboratory's specific needs with the same attention to detail you apply to your writing.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Assemble Square Lab Press Mold for Laboratory Applications

- Cylindrical Press Mold with Scale for Lab

- Carbide Lab Press Mold for Laboratory Applications

People Also Ask

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- What are the primary functions of graphite molds in NiCr powder metallurgy? Optimize Your Composite Material Density

- What is the physical role of graphite molds in vacuum hot pressing? Optimize Cu-Al2O3 Composite Densification

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?