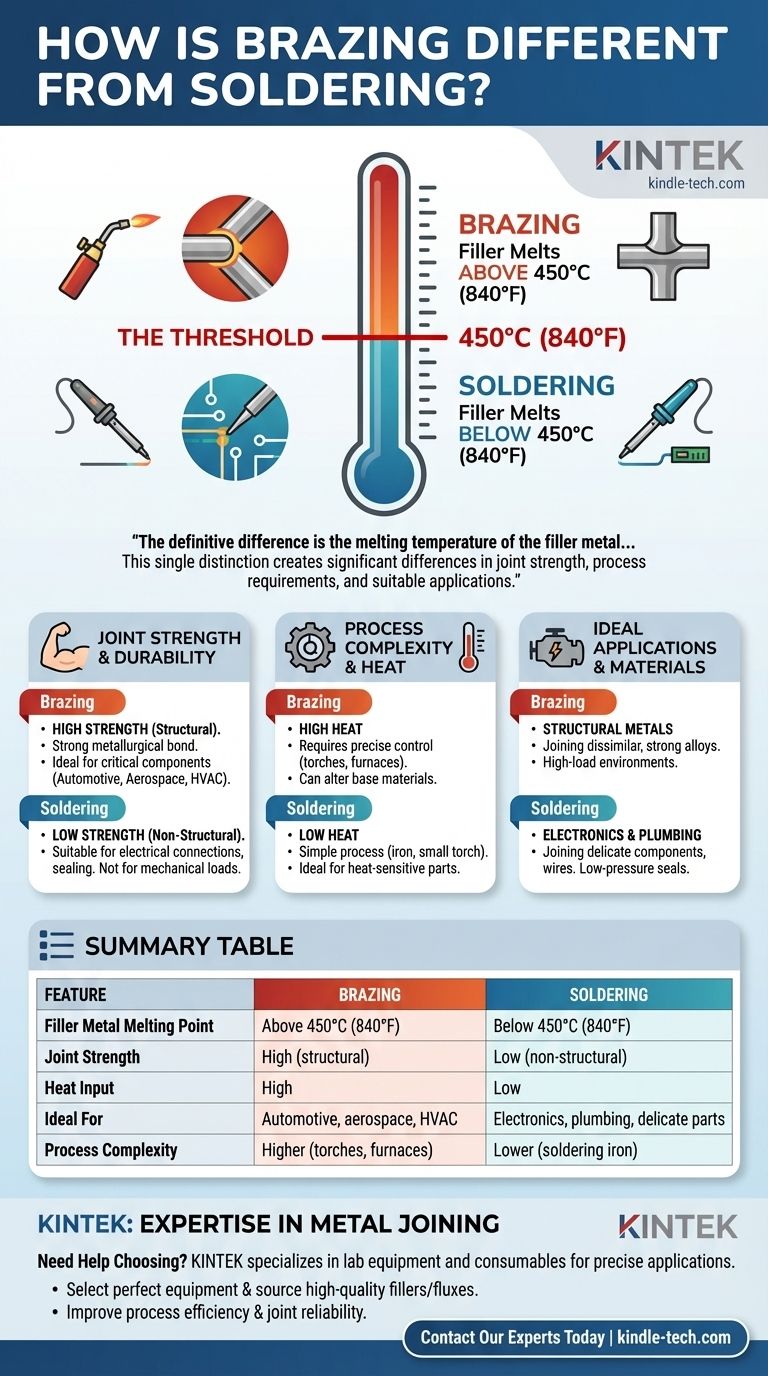

At its core, the definitive difference between brazing and soldering is the melting temperature of the filler metal used to join two components. Brazing uses filler metals that melt above 450°C (840°F), while soldering uses filler metals that melt below this threshold. This single distinction in temperature creates significant differences in joint strength, process requirements, and suitable applications.

The choice between brazing and soldering is fundamentally a trade-off. Brazing provides superior joint strength at the cost of higher heat and process complexity, while soldering offers a lower-temperature, simpler process ideal for heat-sensitive or non-structural applications.

The Defining Difference: Temperature

The 450°C (840°F) line isn't arbitrary; it's the internationally recognized standard that separates the two processes. Understanding this threshold is the first step to choosing the correct method.

The 450°C (840°F) Threshold

This specific temperature is the formal dividing line. Any process using a filler metal that liquifies below this point is technically soldering, and any process above it is brazing.

Critically, in both methods, the base materials being joined do not melt. The filler metal melts, is drawn into the joint through capillary action, and then solidifies to form the bond.

How Filler Metal Dictates Temperature

The melting point is determined by the filler metal's composition. Brazing fillers are typically strong alloys of brass, bronze, aluminum, or silver.

Soldering fillers, or "solder," are typically alloys of tin, often combined with silver, copper, or bismuth, which have much lower melting points.

Practical Implications of the Temperature Gap

The difference in heat required for brazing versus soldering has a direct impact on the final product's performance, cost, and appearance.

Joint Strength and Durability

Brazing creates a significantly stronger joint. The higher temperatures promote better wetting and metallurgical diffusion between the filler and base metals, creating a bond that can be as strong as the materials being joined.

This high strength makes brazing the preferred method for critical components in the automotive, aerospace, and HVAC industries.

Soldered joints are weaker. They are perfectly suitable for creating electrical connections or sealing non-structural joints (like in plumbing), but they are not designed to bear significant mechanical loads.

Process Complexity and Equipment

Brazing's high heat demands more precise control. It often requires torches, induction coils, or controlled-atmosphere furnaces (like vacuum brazing) to ensure uniform heating and prevent oxidation.

Soldering is generally simpler. It can often be done with a basic soldering iron or a small torch, making it more accessible and less expensive for many applications.

Impact on Base Materials

The high heat of brazing can alter the properties of the base materials. It can anneal (soften) hardened metals or damage sensitive electronic components, requiring careful process control.

Soldering's low heat input makes it the only choice for applications like assembling circuit boards, where high temperatures would instantly destroy the components.

Understanding the Trade-offs

Choosing the stronger method is not always the right answer. An objective analysis reveals clear situations where each process excels.

Why Not Always Choose Brazing for Strength?

The primary drawback of brazing is its high heat input. This can cause distortion or warping in thin parts and can ruin the heat treatment of certain alloys. The process is also slower and typically more expensive than soldering.

When Soldering is the Superior Choice

Soldering is the ideal choice when the primary goal is electrical conductivity or a low-pressure seal, and mechanical strength is not a concern. Its simplicity, low cost, and gentle heat make it perfect for electronics, delicate part assembly, and many plumbing repairs.

Appearance and Post-Processing

Advanced techniques like vacuum brazing produce exceptionally clean, bright joints that are free from oxidation and require no post-process cleaning. This creates high part-to-part consistency.

Soldered joints often require the use of a chemical flux to ensure the solder flows correctly, which can leave behind residue that must be cleaned off.

Making the Right Choice for Your Application

Your final decision must be driven by the specific demands of your project.

- If your primary focus is maximum joint strength and reliability under load: Brazing is the only suitable choice, providing a robust, permanent metallurgical bond.

- If your primary focus is joining heat-sensitive components like electronics: Soldering is the essential method due to its low-temperature application.

- If your primary focus is cost-effectiveness and simplicity for non-structural seals: Soldering provides an excellent balance of utility and ease of use.

By understanding that this choice hinges on the relationship between temperature and strength, you can confidently select the right process to achieve your engineering goal.

Summary Table:

| Feature | Brazing | Soldering |

|---|---|---|

| Filler Metal Melting Point | Above 450°C (840°F) | Below 450°C (840°F) |

| Joint Strength | High (structural) | Low (non-structural) |

| Heat Input | High | Low |

| Ideal For | Automotive, aerospace, HVAC | Electronics, plumbing, delicate parts |

| Process Complexity | Higher (torches, furnaces) | Lower (soldering iron) |

Need Help Choosing the Right Joining Process for Your Lab?

KINTEK specializes in lab equipment and consumables, providing the right tools for precise metal joining applications. Whether you require the high-strength capabilities of brazing or the delicate touch of soldering, our expertise ensures you get optimal results.

We can help you:

- Select the perfect equipment for your specific joining needs

- Source high-quality filler metals and fluxes

- Improve your process efficiency and joint reliability

Let's discuss your project requirements. Contact our experts today for personalized solutions that enhance your laboratory's capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints