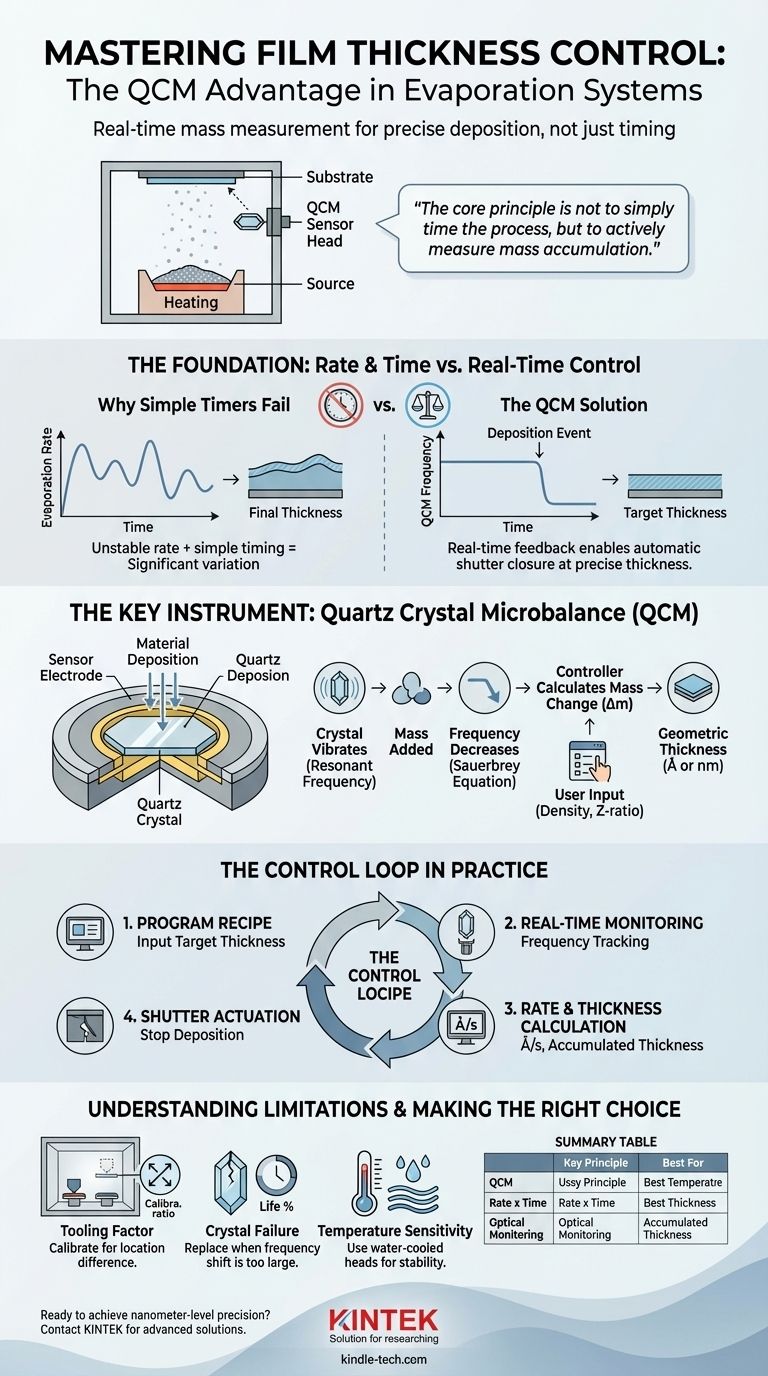

In an evaporation system, film thickness is primarily controlled by using a Quartz Crystal Microbalance (QCM) to monitor the material deposition rate in real-time. This device measures the mass accumulating on a sensor crystal, allowing the system's controller to calculate the current thickness and automatically close a shutter to stop the deposition process once the desired thickness is achieved.

The core principle is not to simply time the process, but to actively measure mass accumulation. By monitoring the changing frequency of a quartz crystal as material deposits onto it, you can achieve precise, real-time control over the final film thickness.

The Foundation: Rate and Time

The most basic concept for controlling thickness is a simple relationship: Thickness = Deposition Rate × Time. However, relying on this alone is often insufficient for achieving precise and repeatable results.

The Instability of Evaporation Rate

The rate at which material evaporates from a source is not perfectly constant. It can fluctuate due to several factors, including thermal instabilities in the heating element, depletion of the source material, and changes in pressure within the vacuum chamber.

Why Simple Timers Fail

Because the rate is variable, simply opening a shutter for a pre-calculated amount of time leads to significant variations in final film thickness. To achieve precision, you must measure the rate and accumulated thickness as the process happens.

The Key Instrument: The Quartz Crystal Microbalance (QCM)

The QCM is the workhorse for thickness control in nearly all modern thermal and e-beam evaporation systems. It provides the real-time feedback necessary for precise control.

How a QCM Works

A QCM sensor head contains a thin, disc-shaped quartz crystal sandwiched between two electrodes. An oscillator circuit drives the crystal to vibrate at its natural resonant frequency.

As material from the evaporation source coats the crystal, the added mass slows down this vibration, causing a measurable decrease in frequency.

From Frequency Shift to Mass

This relationship between mass and frequency is highly linear and is described by the Sauerbrey equation. A dedicated film thickness controller continuously measures this frequency shift (Δf) and uses it to calculate the change in mass (Δm) on the crystal surface.

Converting Mass to Geometric Thickness

The controller then uses two user-defined parameters—the density of the material being deposited and its acoustic impedance factor (Z-ratio)—to convert the calculated mass per unit area into a geometric thickness, typically displayed in Angstroms (Å) or nanometers (nm).

The Control Loop in Practice

A typical deposition process follows a closed-loop control sequence to achieve the target thickness.

1. Programming the Recipe

The user inputs the target thickness and the material's density and Z-ratio into the film thickness controller. This "programs" the system for the desired outcome.

2. Real-Time Monitoring

Once the source is heated and the shutter opens, deposition begins on both the substrate and the QCM sensor crystal. The controller immediately starts tracking the decrease in the crystal's frequency.

3. Rate and Thickness Calculation

From the frequency data, the controller calculates the instantaneous deposition rate (e.g., in Å/second) and the total accumulated thickness. This information is displayed for the operator.

4. Shutter Actuation

When the controller's calculated thickness matches the user's target thickness, it sends a signal to an actuator that instantly closes the shutter. This stops any more material from reaching the substrate, terminating the deposition at the precise moment.

Understanding the Trade-offs and Limitations

While the QCM is a powerful tool, achieving true accuracy requires understanding its limitations and proper calibration.

The "Tooling Factor"

A QCM measures the film thickness at its specific location inside the chamber, which is almost never the same as the substrate's location. The amount of material received can differ due to the geometry of the chamber.

A tooling factor is a calibration ratio that corrects for this discrepancy. It is determined by depositing a film, measuring the thickness on the QCM, and then independently measuring the actual thickness on the substrate (e.g., with a profilometer). This ratio is then programmed into the controller for all future runs.

QCM Crystal Failure

The quartz crystal has a finite life. As material builds up, the frequency shift becomes too large, and the oscillation can become unstable or stop entirely. At this point, the crystal must be replaced. Most controllers track "crystal life" as a percentage to signal when replacement is needed.

Temperature Sensitivity

The resonant frequency of quartz is also sensitive to temperature changes. A sudden increase in heat from the evaporation source can cause the frequency to drift, leading to an inaccurate thickness reading. High-quality QCM sensor heads are water-cooled to maintain a stable temperature and ensure accurate measurements.

Making the Right Choice for Your Goal

Your strategy for thickness control depends on your application's required precision and the materials you are using.

- If your primary focus is repeatable metal deposition: A properly calibrated QCM with a stable tooling factor is the industry standard and provides excellent, reliable control.

- If your primary focus is high-precision optical coatings: Consider a system that combines a QCM for stable rate control with an in-situ optical monitor that measures the film's reflective or transmissive properties to terminate the layer.

- If your primary focus is R&D or process development: Always start by establishing a reliable tooling factor. Use a QCM for real-time control, but verify your results with an external (ex-situ) measurement tool like a profilometer or ellipsometer.

Mastering thickness control is fundamental to transforming the art of thin-film deposition into a precise and repeatable science.

Summary Table:

| Method | Key Principle | Best For |

|---|---|---|

| Quartz Crystal Microbalance (QCM) | Real-time mass measurement via frequency shift of a quartz crystal. | Reliable, repeatable metal deposition; general thin-film processes. |

| Rate × Time (Manual) | Simple calculation based on assumed constant evaporation rate. | Basic applications where high precision is not critical. |

| Optical Monitoring | In-situ measurement of film's optical properties (reflectance/transmittance). | High-precision optical coatings where performance is critical. |

Ready to achieve nanometer-level precision in your lab?

KINTEK specializes in high-quality lab equipment, including evaporation systems with advanced QCM thickness control. Our solutions ensure the repeatability and accuracy your research or production demands.

Contact us today to discuss your specific thin-film deposition needs and let our experts help you select the perfect system.

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Automatic Laboratory Heat Press Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

People Also Ask

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What is a calendering machine? Transform Material Surfaces with Precision

- What is the role of a laboratory crushing and sieving system in microalgae pyrolysis? Enhance Your Yield Efficiency

- How does a grinding mill work? A Guide to Crushing, Grinding, and Pulverizing

- What is the principle of calendering? Enhance Fabric Surface with Heat and Pressure