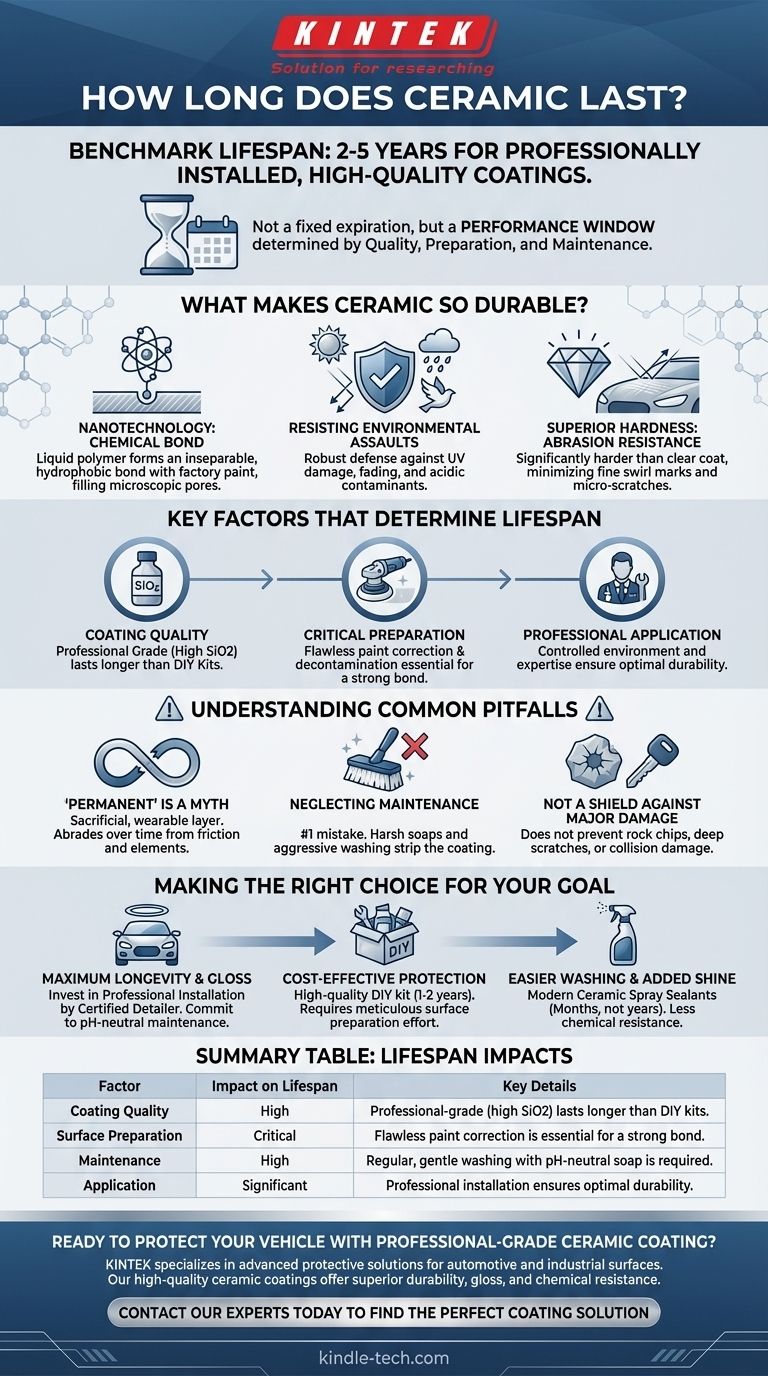

In practice, a professionally installed, high-quality ceramic coating will last between 2 and 5 years. This lifespan is not a guarantee but a benchmark, as some top-tier professional coatings can offer protection for a decade or more. The ultimate durability, however, depends less on the product's claims and more on the quality of the application and the diligence of its care.

A ceramic coating's lifespan is not a fixed expiration date. It is a performance window determined by three key factors: the quality of the coating, the precision of the initial surface preparation, and the consistency of post-application maintenance.

What Makes Ceramic So Durable?

To understand a coating's lifespan, we must first understand what it is. A true ceramic coating isn't just a layer of wax; it's a liquid polymer that forms a powerful chemical bond with a vehicle's factory paint.

The Science of Nanotechnology

At its core, a ceramic coating uses nanotechnology to create an inseparable bond with the surface. It fills the microscopic pores in the clear coat, forming a smooth, extremely hard, and hydrophobic (water-repellent) layer of protection. This is a semi-permanent bond, unlike waxes that simply sit on the surface.

Resisting Environmental Assaults

The intrinsic properties of ceramic materials provide robust defense against common threats. Its oxidation and corrosion resistance helps shield the paint from UV ray damage, which causes fading, and from acidic contaminants like bird droppings and acid rain.

Superior Hardness

Ceramic coatings cure to a hardness level that is significantly greater than a factory clear coat. This high abrasion resistance helps minimize the appearance of fine swirl marks and micro-scratches that occur during routine washing, preserving the paint's flawless finish.

Key Factors That Determine Lifespan

The advertised lifespan of a coating is only achievable under ideal conditions. Several variables have a dramatic impact on real-world performance.

The Quality of the Coating

Not all coatings are created equal. Professional-grade coatings typically contain a higher concentration of Silicon Dioxide (SiO2), the primary active ingredient. This results in a thicker, harder, and more durable layer of protection compared to many consumer-grade "DIY" products.

The Critical Role of Preparation

A ceramic coating will only last if the surface it bonds to is perfect. Proper surface preparation is the most crucial step in the entire process. This involves a multi-stage process of washing, clay bar decontamination, and, most importantly, paint correction (polishing) to remove all imperfections. Any contaminants or scratches sealed under the coating will be there permanently and will compromise the bond's integrity.

Professional vs. DIY Application

A professional installer works in a controlled environment, has specialized tools, and possesses the expertise to perform flawless paint correction. While DIY kits have become more accessible, achieving a professional-level bond that lasts for years is exceptionally difficult without the right skills and environment.

Understanding the Common Pitfalls

Many users are disappointed when their coating fails prematurely. This is almost always due to misconceptions about what a coating is and how it must be treated.

"Permanent" Is a Myth

No coating is truly permanent or indestructible. It is a sacrificial, wearable layer designed to take the damage that your paint would otherwise endure. Over years of exposure to the elements and friction from washing, it will slowly abrade away.

Neglecting Maintenance Is the #1 Mistake

This is the single most common reason for premature failure. A ceramic coating is not a "set it and forget it" solution. Using harsh, high-pH soaps found in automatic car washes or aggressive washing techniques will strip the coating and drastically reduce its lifespan.

It Is Not a Shield Against Major Damage

A ceramic coating is a formidable defense against chemical and environmental hazards. It is not a shield against physical impacts. It will not prevent rock chips, deep scratches from keys, or damage from collisions. For that level of protection, Paint Protection Film (PPF) is required.

Making the Right Choice for Your Goal

To maximize the life of your coating, align your choice and maintenance plan with your ultimate objective.

- If your primary focus is maximum longevity and gloss: Invest in a professional-grade coating installed by a certified detailer and commit to their recommended maintenance schedule using pH-neutral soaps.

- If your primary focus is cost-effective protection: A high-quality DIY kit can provide 1-2 years of excellent durability, but only if you are willing to invest significant time and effort in meticulous surface preparation first.

- If your primary focus is simply easier washing and added shine: Modern ceramic spray sealants offer many of the same hydrophobic properties, but their lifespan is measured in months, not years, and they offer far less chemical resistance.

Ultimately, the lifespan of a ceramic coating is a direct reflection of the care and maintenance it receives.

Summary Table:

| Factor | Impact on Lifespan | Key Details |

|---|---|---|

| Coating Quality | High | Professional-grade (high SiO2) lasts longer than DIY kits. |

| Surface Preparation | Critical | Flawless paint correction is essential for a strong bond. |

| Maintenance | High | Regular, gentle washing with pH-neutral soap is required. |

| Application | Significant | Professional installation ensures optimal durability. |

Ready to protect your vehicle with a professional-grade ceramic coating? At KINTEK, we specialize in advanced protective solutions for automotive and industrial surfaces. Our high-quality ceramic coatings offer superior durability, gloss, and chemical resistance, ensuring your investment is protected for years. Contact our experts today to find the perfect coating solution for your needs!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Hexagonal Boron Nitride HBN Ceramic Ring

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures

- What is the thermal expansion of SiC? Master Its Low CTE for Superior High-Temp Performance

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C