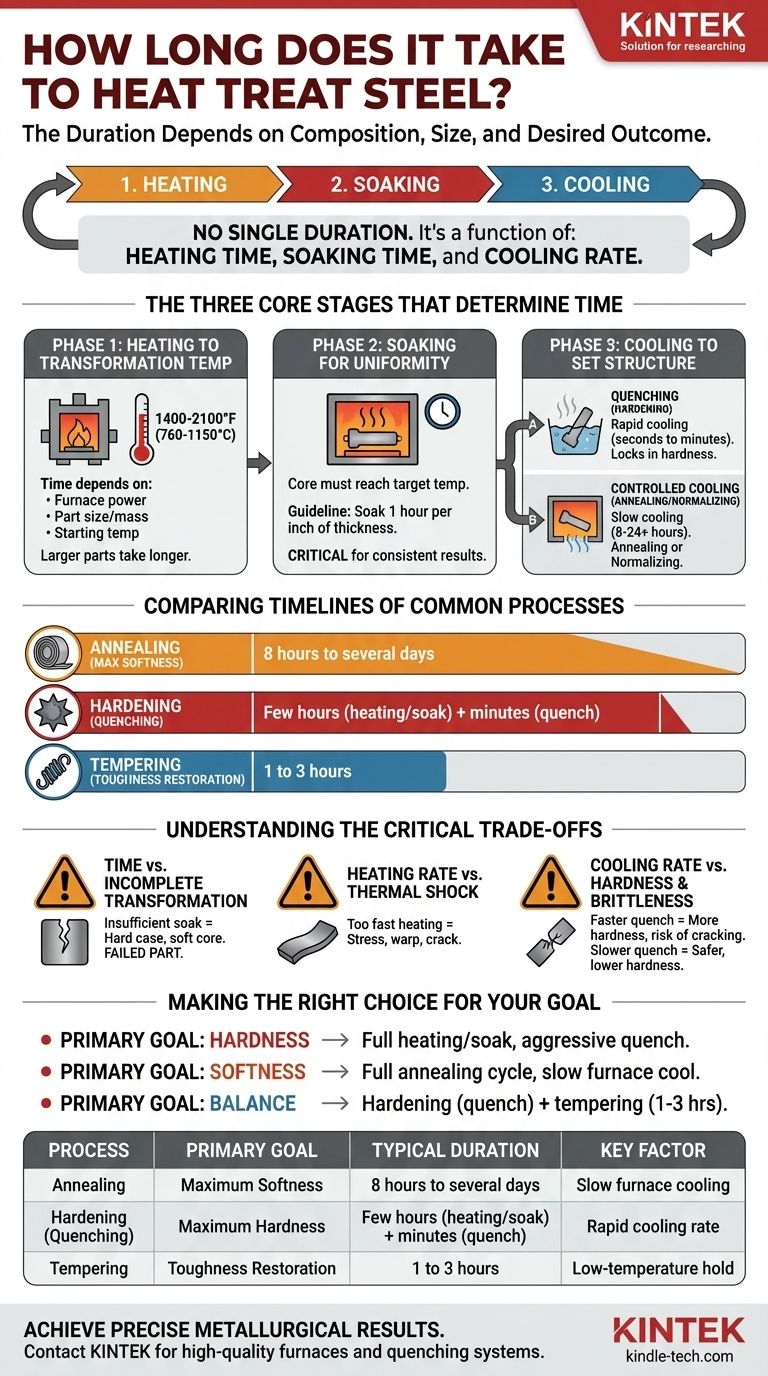

Stating a single duration for heat treating steel is impossible because the time is dictated entirely by the steel's composition, the part's size, and the desired outcome. The total process time can range from a few hours for a small, simple part to several days for a large, complex component undergoing a full annealing cycle. The key variables are the specific temperatures required, the time needed for the steel's internal structure to transform, and the rate at which it must be cooled.

The time required for heat treatment is not a fixed number, but a function of three critical stages: the time to heat to a target temperature, the time to soak at that temperature for full structural transformation, and the time and rate of cooling to lock in the new properties.

The Three Core Stages That Determine Time

Every heat treatment process, regardless of its name, consists of three distinct phases. The duration of each phase is determined by physics and metallurgy, not just a clock.

Phase 1: Heating to Transformation Temperature

The first step is heating the steel to a specific temperature where its crystalline structure can change. This is often the austenitizing temperature, typically between 1400-2100°F (760-1150°C).

The time this takes depends on the furnace's power, the part's size and mass, and its starting temperature. A larger, thicker component naturally takes much longer to heat through than a small, thin one.

Phase 2: Soaking for Uniformity

Once the surface of the steel reaches the target temperature, the core will still be cooler. The soaking phase involves holding the part at that temperature until it is heated uniformly all the way through.

This is the most critical phase for ensuring a consistent result. An incomplete soak means only the outer "shell" of the part transforms, leading to soft spots and unreliable performance. A common industry guideline is to soak for one hour for every inch of thickness at the part's thickest cross-section, but this is only a starting point.

Phase 3: Cooling to Set the Structure

This is where the desired properties are locked in. The rate of cooling is often more important than the duration itself, but the two are linked. The cooling method dictates the final microstructure and, therefore, the steel's hardness and toughness.

- Quenching (Hardening): Involves extremely rapid cooling in a medium like water, oil, or forced air. This process can take mere seconds to minutes.

- Controlled Cooling (Annealing/Normalizing): Involves much slower cooling. This can mean shutting off the furnace and letting it cool over 8-24+ hours (annealing) or simply letting the part cool in still air (normalizing).

Comparing Timelines of Common Processes

The combination of the three stages results in vastly different total times for different treatments.

Annealing (Maximum Softness)

The goal of annealing is to make steel as soft and ductile as possible. This requires the slowest process. After a thorough soak, the furnace is very slowly cooled over many hours or even days to ensure the softest possible structure forms.

- Typical Duration: 8 hours to several days.

Hardening (Quenching)

Hardening aims to create maximum hardness by trapping the steel in its hardest possible state. This involves heating, soaking, and then an immediate, aggressive quench.

- Typical Duration: The heating and soaking might take a few hours, but the critical cooling phase is over in minutes.

Tempering (Toughness Restoration)

Hardened steel is extremely brittle. Tempering is a secondary process performed after quenching to restore some toughness. The part is re-heated to a much lower temperature (e.g., 400-1100°F or 205-595°C) and held for a set time.

- Typical Duration: 1 to 3 hours at the tempering temperature is common for most tools and components.

Understanding the Critical Trade-offs

Rushing the heat treatment process is a primary cause of failed parts. Understanding the compromises is essential.

Time vs. Incomplete Transformation

The most common mistake is an insufficient soak time. If the core of the part does not fully transform, it will not harden properly during the quench. This leaves a hard case with a soft, weak core, making the part unfit for its intended purpose.

Heating Rate vs. Thermal Shock

Heating a complex part with thick and thin sections too quickly creates immense internal stress. The thin sections expand faster than the thick ones, which can cause the part to warp or even crack before it ever reaches the soaking temperature.

Cooling Rate vs. Hardness & Brittleness

This is the fundamental trade-off in hardening steel. A faster quench yields greater hardness but also increases internal stress and the risk of cracking. A slower quench is safer and reduces brittleness but results in lower overall hardness. The correct quench speed is specific to the steel alloy being used.

Making the Right Choice for Your Goal

Your desired outcome is the ultimate factor that determines the necessary process and its duration.

- If your primary focus is creating the hardest possible part: You will need a full heating and soaking cycle followed by the most aggressive quench the specific steel can survive without cracking.

- If your primary focus is maximum softness and machinability: You must commit to a full annealing cycle, which requires a very long, slow cool-down period inside the furnace.

- If your primary focus is a balance of hardness and toughness: Your process will involve hardening (quenching) followed immediately by a precise tempering cycle of 1-3 hours to relieve brittleness.

Ultimately, the correct duration for heat treatment is the time required to achieve the exact metallurgical structure your application demands.

Summary Table:

| Process | Primary Goal | Typical Duration | Key Factor |

|---|---|---|---|

| Annealing | Maximum Softness | 8 hours to several days | Slow furnace cooling |

| Hardening (Quenching) | Maximum Hardness | Few hours (heating/soak) + minutes (quench) | Rapid cooling rate |

| Tempering | Toughness Restoration | 1 to 3 hours | Low-temperature hold |

Achieve precise metallurgical results for your steel components. The right heat treatment process is critical for performance, and having reliable equipment is the first step. KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-quality furnaces and quenching systems designed for accurate temperature control and uniform heating. Contact us today to discuss how our solutions can enhance your heat treatment outcomes and ensure consistent, high-quality results for your specific applications.

Get in touch with our experts to find the perfect heat treatment equipment for your lab.

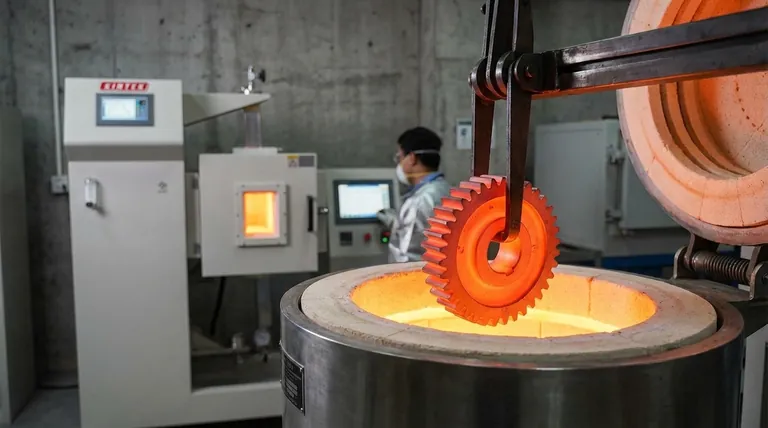

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results