To be direct, PVD coating is exceptionally scratch-resistant and one of the most durable finishes available today. While not completely scratch-proof, it vastly outperforms traditional coatings and can maintain its appearance for a decade or more with basic care. It resists the wear and tear of daily use far better than non-coated or traditionally plated materials.

The core value of PVD is not total invincibility, but rather a superior level of hardness and adhesion that provides remarkable, long-term resistance to the scuffs and abrasions that would quickly degrade lesser finishes.

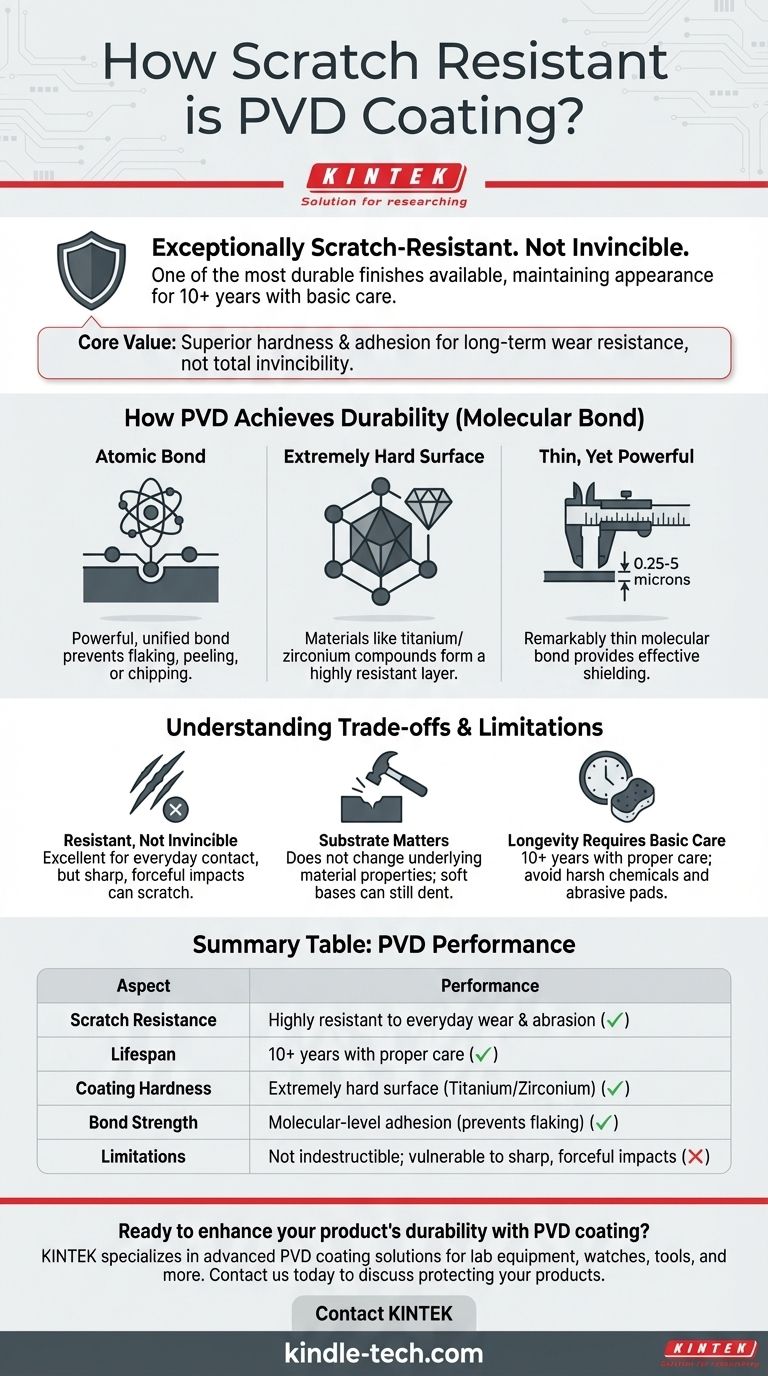

How PVD Achieves Its Durability

Physical Vapor Deposition (PVD) isn't a simple layer of paint. It is a high-tech vacuum deposition process where a solid material is vaporized and then bonded to the surface of a product at a molecular level. This fundamental difference is the source of its strength.

A Bond at the Atomic Level

The PVD process creates a powerful, unified bond between the coating and the base material (the substrate). This means the finish is highly unlikely to flake, peel, or chip the way a painted or electroplated surface can.

An Extremely Hard Surface

The materials used for PVD coatings, often compounds of titanium or zirconium, are inherently very hard. This creates a surface layer that is highly resistant to being breached by minor impacts and abrasive forces.

Thin, Yet Powerful

A PVD coating is remarkably thin, typically between 0.25 and 5 microns. Despite this, its molecular bond and inherent hardness provide a protective layer that effectively shields the material underneath from wear.

Understanding the Trade-offs and Limitations

To make an informed decision, you must understand what PVD can and cannot do. Its reputation for toughness is well-earned, but it is not indestructible.

Resistant, Not Invincible

PVD is excellent at resisting scratches from everyday contact. However, a forceful, sharp impact from another hard object can still scratch or gouge the coating. It can, as the reference material notes, "pick up a scratch or two over the years."

The Substrate Still Matters

PVD adds surface hardness, but it does not change the properties of the underlying material. If a PVD coating is applied to a soft metal like aluminum, a significant impact can still dent the item—and the coating will dent along with it.

Longevity Requires Basic Care

A PVD finish can easily last for 10 years or more, but its lifespan depends on its environment. Avoiding harsh chemical cleaners and highly abrasive scouring pads will ensure the finish maintains its integrity and appearance.

How to Apply This to Your Decision

Your choice depends entirely on your goal for the product. PVD is a premium finish that offers a clear performance advantage in the right applications.

- If your primary focus is everyday resilience for items like watches or faucets: PVD is an outstanding choice that will keep the product looking new for years, far outlasting traditional options.

- If your primary focus is color durability on high-contact items: PVD is the superior method for applying colors like black, bronze, or gold that would quickly wear off with other coating methods.

- If your primary focus is protecting tools from extreme, heavy-impact abuse: While PVD adds significant protection, remember that it is still a coating and can be breached by severe force.

Ultimately, choosing a PVD-coated product is an investment in superior longevity and resilience against the wear and tear of daily life.

Summary Table:

| Aspect | PVD Coating Performance |

|---|---|

| Scratch Resistance | Highly resistant to everyday wear and abrasion |

| Lifespan | 10+ years with proper care |

| Coating Hardness | Extremely hard surface from titanium/zirconium compounds |

| Bond Strength | Molecular-level adhesion prevents flaking and peeling |

| Limitations | Not indestructible; can be damaged by sharp, forceful impacts |

Ready to enhance your product's durability with PVD coating?

At KINTEK, we specialize in advanced lab equipment and consumables, including PVD coating solutions that deliver superior scratch resistance and longevity. Whether you're manufacturing watches, tools, or decorative hardware, our expertise ensures a finish that stands up to daily wear while maintaining its appearance for years.

Contact us today to discuss how our PVD coating services can protect your products and add value for your customers.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition