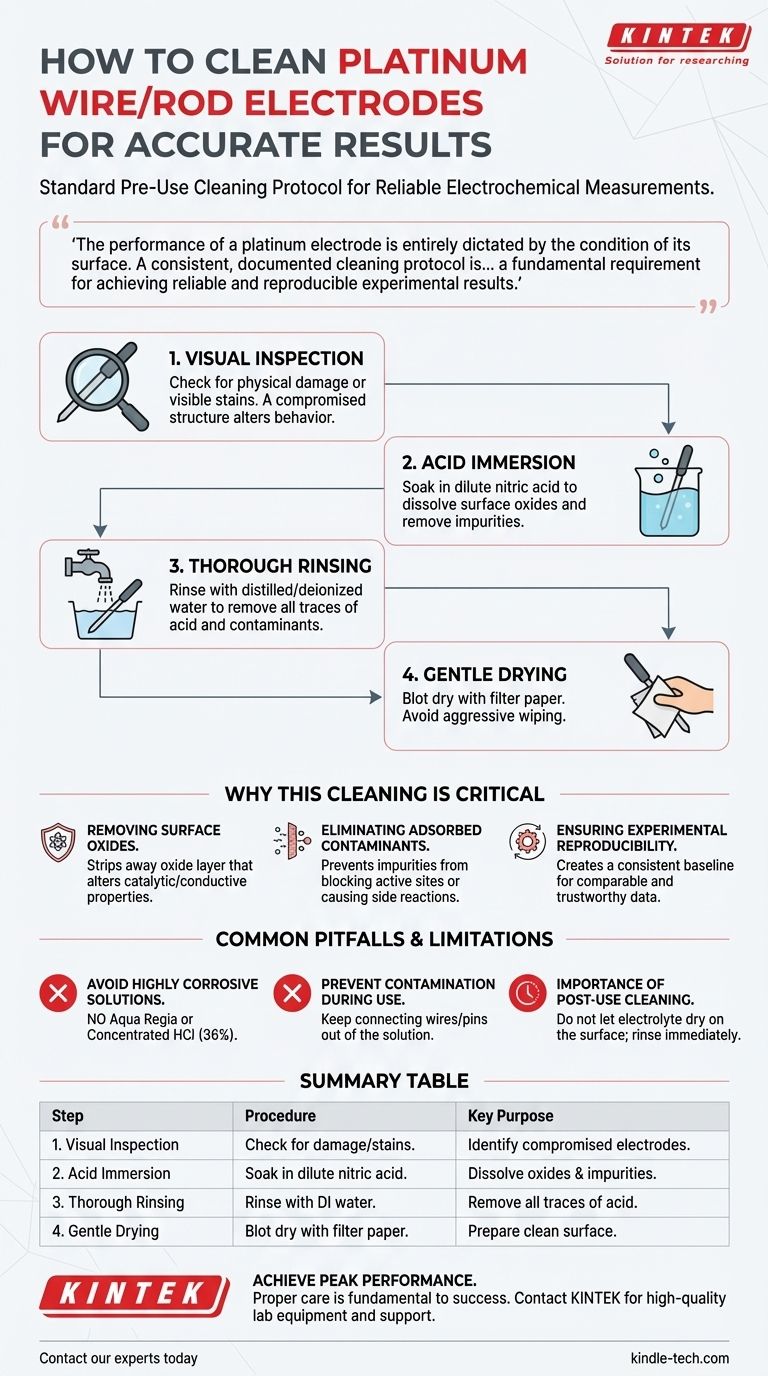

To ensure accurate electrochemical measurements, a platinum wire or rod electrode must be cleaned before use to remove surface oxides and contaminants. The standard procedure is to immerse the electrode in a dilute acid solution, such as nitric acid, followed by a thorough rinse with distilled or deionized water. This simple but critical process restores the electrode's active surface.

The performance of a platinum electrode is entirely dictated by the condition of its surface. A consistent, documented cleaning protocol is not merely a preparatory step; it is a fundamental requirement for achieving reliable and reproducible experimental results.

The Standard Pre-Use Cleaning Protocol

A clean electrode surface is the baseline for any valid electrochemical experiment. Following a systematic procedure prevents errors and ensures your data is a true reflection of the chemical system, not of surface contamination.

Step 1: Visual Inspection

Before any chemical treatment, always visually inspect the electrode. Look for any signs of physical damage, bending, or significant, visible stains. A compromised physical structure can alter electrochemical behavior just as much as chemical impurities.

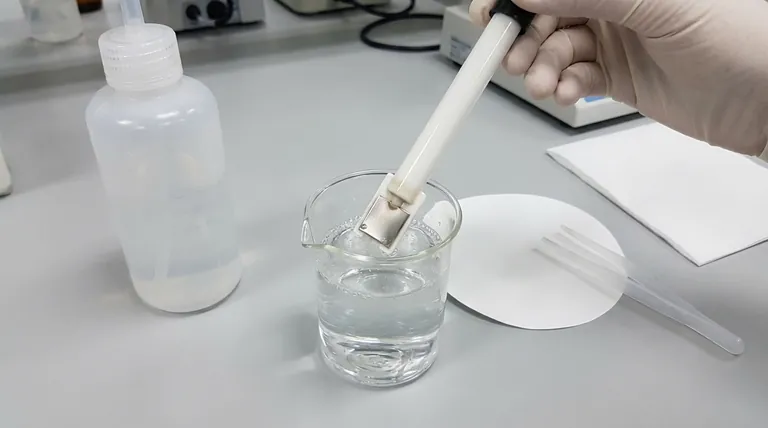

Step 2: Acid Immersion

The primary cleaning step involves soaking the platinum portion of the electrode in a dilute acid. Dilute nitric acid is a common and effective choice. This acid bath serves to dissolve surface oxides and remove many metallic and organic impurities that may have adsorbed onto the surface.

Step 3: Thorough Rinsing

This step is as critical as the acid wash. After removing the electrode from the acid, rinse it thoroughly with high-purity water, such as distilled or deionized water. The goal is to remove all traces of the cleaning acid and any contaminants that were lifted from the surface. Inadequate rinsing will simply replace one contaminant with another.

Step 4: Gentle Drying

After the final rinse, gently dry the electrode. For most applications, this can be done by carefully blotting the surface with a piece of filter paper. Avoid aggressive wiping, which could re-contaminate the surface or alter its roughness.

Why This Cleaning is Critical

Failing to properly clean a platinum electrode introduces significant variables into your experiment, undermining the validity of your results. The entire premise of electrochemistry relies on a well-defined interface between the electrode and the electrolyte.

Removing Surface Oxides

Platinum can form a thin layer of platinum oxide on its surface when exposed to air or certain electrochemical conditions. This oxide layer has different catalytic and conductive properties than pure platinum, which will alter the measured results. The acid wash effectively strips this layer away.

Eliminating Adsorbed Contaminants

The surface of platinum is highly active and can adsorb various molecules from the atmosphere or previous experiments. These impurities can block active sites, participate in side reactions, or poison the catalytic process you intend to study, leading to inaccurate data.

Ensuring Experimental Reproducibility

By starting every experiment with an electrode prepared in the exact same way, you create a consistent baseline. This practice is the foundation of reproducibility, allowing you to confidently compare results from different trials and ensuring that observed changes are due to your experimental variables, not a fluctuating electrode condition.

Common Pitfalls and Limitations

Proper care extends beyond pre-use cleaning. Understanding the electrode's limitations and handling it correctly are essential for its longevity and performance.

Avoid Highly Corrosive Solutions

Never expose a platinum electrode to substances that will attack the metal itself. Aqua regia and concentrated hydrochloric acid (36%) are extremely corrosive to platinum and will permanently damage the electrode. Always verify chemical compatibility before use.

Prevent Contamination During Use

Handle the electrode carefully to ensure that only the platinum wire or mesh comes into contact with the electrolyte. Allowing the connecting wires, pins, or clamps to touch the solution can introduce metallic ions and ruin your experiment.

The Importance of Post-Use Cleaning

Do not let electrolyte dry on the electrode surface after an experiment. Immediately after use, remove the electrode from the cell, rinse it with deionized water, and dry it. This prevents the crystallization of salts and buildup of stubborn residues, making the next pre-use cleaning far more effective.

Making the Right Choice for Your Goal

Implementing a disciplined care regimen is essential for anyone performing serious electrochemical work.

- If your primary focus is routine analysis: Always perform the standard dilute acid soak and deionized water rinse before each set of experiments to establish a consistent analytical baseline.

- If you suspect significant contamination from a previous run: Consider a longer soak time or an ultrasonic cleaning step with deionized water after the acid wash to dislodge more stubborn residues.

- For long-term storage and integrity: Ensure the electrode is cleaned and dried immediately after its final use, then store it in a dedicated, clean container to protect it from physical damage and atmospheric contaminants.

Ultimately, treating your electrode with methodical care is the first and most important step toward generating trustworthy and publishable electrochemical data.

Summary Table:

| Step | Procedure | Key Purpose |

|---|---|---|

| 1. Visual Inspection | Check for physical damage or stains. | Identify compromised electrodes before use. |

| 2. Acid Immersion | Soak in dilute nitric acid. | Dissolve surface oxides and remove impurities. |

| 3. Thorough Rinsing | Rinse with distilled/deionized water. | Remove all traces of acid and contaminants. |

| 4. Gentle Drying | Blot dry with filter paper. | Prepare a clean, dry surface for experiments. |

Achieve peak performance and longevity for your lab's electrochemical equipment.

Proper electrode care is fundamental to experimental success. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools and expert support your laboratory needs for precise electrochemical analysis.

Contact our experts today to discuss your specific requirements and ensure your lab is equipped for accurate, reproducible results.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Gold Electrochemical Sheet Electrode Gold Electrode

- Gold Disc Electrode

People Also Ask

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What are the key performance characteristics and applications of platinum sheets? Unmatched Reliability for Demanding Applications

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data