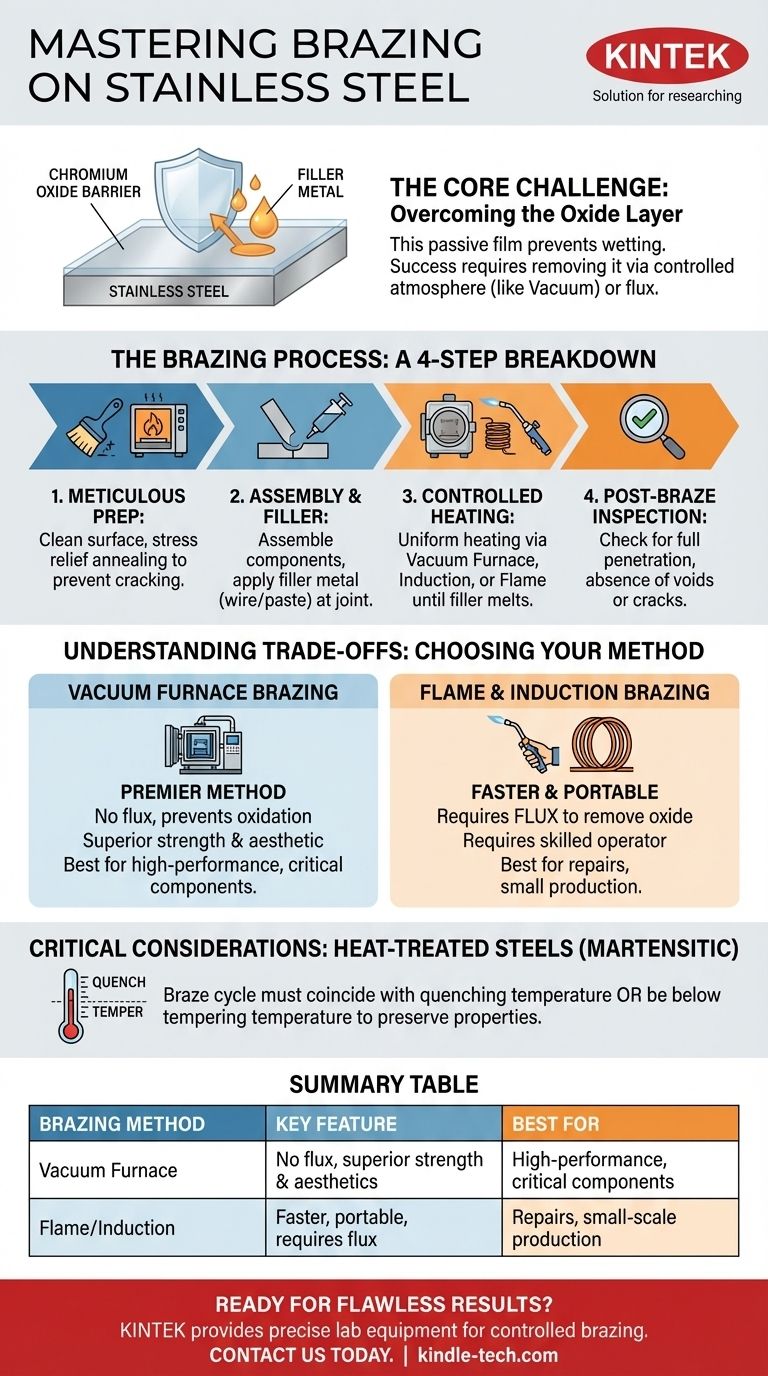

To braze stainless steel successfully, you must first meticulously prepare the surface to remove its naturally occurring oxide film. The process then requires a controlled heating method—such as a vacuum furnace, flame, or induction—to melt a filler metal that flows into the joint, creating a strong, permanent bond upon cooling. The key is managing the atmosphere during heating to prevent the oxide layer from re-forming.

The fundamental challenge in brazing stainless steel is not the steel itself, but the invisible, passive layer of chromium oxide on its surface. Your entire process must be designed around either removing this layer and preventing its return, or using a chemical flux to displace it during heating.

The Core Challenge: Overcoming the Oxide Layer

Brazing works by creating a metallurgical bond between a filler metal and the base materials. For this to happen, the liquid filler metal must be able to "wet" the surface of the steel, meaning it must flow and spread evenly across it.

Why Stainless Steel Resists Brazing

The very property that makes stainless steel "stainless"—its passive chromium oxide film—is the primary barrier to successful brazing. This tough, transparent layer forms instantly when the steel is exposed to air.

This oxide film prevents the molten filler metal from making direct contact with the underlying steel, inhibiting proper wetting and bonding.

The Principle of Atmosphere Control

To achieve a strong brazed joint, you must overcome this oxide barrier. This is accomplished by controlling the atmosphere around the part during the high-temperature brazing cycle.

The most effective method is vacuum brazing, where a high vacuum removes oxygen from the environment. At high temperatures, the vacuum helps break down the existing oxide layer and prevents a new one from forming, allowing the filler metal to wet the pure steel surface.

A Breakdown of the Brazing Process

A successful outcome depends on a systematic and controlled approach. Each step is critical for ensuring the final integrity of the joint.

Step 1: Meticulous Preparation

Before heating, the workpiece must be perfectly clean. More importantly, to prevent cracking, it should undergo stress relief annealing, especially if it has been heavily machined or formed. This reduces internal stresses that can be released during the thermal cycle.

Step 2: Assembly and Filler Metal Application

The components are assembled into their final configuration. The brazing filler metal, chosen for its compatibility with stainless steel, is placed at or near the joint in the form of wire, paste, or foil.

Step 3: Controlled Heating and Brazing

The assembly is heated uniformly to the brazing temperature. Uniform heating is critical to minimize thermal stress and prevent distortion or cracking.

The chosen heating method—vacuum furnace, induction coil, or flame—is applied until the filler metal melts and is drawn into the joint by capillary action.

Step 4: Post-Braze Inspection

After cooling, the brazed joint is inspected for completeness and integrity. Technicians look for full penetration of the filler metal and the absence of voids or cracks.

Understanding the Trade-offs: Choosing Your Method

The heating method you choose has a significant impact on the cost, speed, and quality of the final joint.

Vacuum Furnace Brazing

This is the premier method for high-performance applications. By performing the process in a high vacuum, it eliminates the need for chemical fluxes and prevents oxidation.

The result is an exceptionally strong, clean, and aesthetically pleasing joint with superior mechanical properties. However, it requires significant capital investment and is a batch process, making it less suitable for single-piece work.

Flame and Induction Brazing

These methods are faster and more portable, making them suitable for repairs or smaller production runs. They are less expensive upfront than a vacuum furnace.

However, both methods typically require a chemical flux to dissolve the oxide layer. This flux can be corrosive and must be completely removed after brazing. These methods also demand a high level of operator skill to achieve uniform heating and avoid overheating the part.

Critical Considerations for Heat-Treated Steels

Working with certain grades of stainless steel, particularly martensitic grades, adds another layer of complexity. The brazing process must be integrated with the material's heat treatment requirements.

Martensitic Steels and Heat Treatment

For martensitic stainless steel, the brazing temperature must be carefully selected.

You can either design the brazing cycle to coincide with the material's quenching temperature, effectively combining the two processes. Alternatively, you must braze at a temperature lower than the tempering temperature to avoid softening the steel and losing its desired mechanical properties.

Making the Right Choice for Your Goal

Your application's requirements will dictate the most appropriate brazing strategy.

- If your primary focus is maximum joint strength, cleanliness, and reliability: Vacuum furnace brazing is the definitive choice for critical components.

- If your primary focus is rapid, small-scale production or field repair: Flame or induction brazing with the correct flux is a viable option, provided you have a skilled operator.

- If you are working with heat-treated martensitic steels: You must design the thermal cycle around the material's specific heat treatment temperatures to preserve its integrity.

Properly addressing the unique properties of stainless steel is the key to creating a brazed joint that is as strong and reliable as the parent metal itself.

Summary Table:

| Brazing Method | Key Feature | Best For |

|---|---|---|

| Vacuum Furnace | No flux, superior strength & aesthetics | High-performance, critical components |

| Flame/Induction | Faster, portable, requires flux | Repairs, small-scale production |

Ready to achieve flawless brazing results on your stainless steel components?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for controlled brazing processes. Whether you're working with vacuum furnaces or flux-based methods, our expertise ensures you get strong, reliable joints every time.

Contact us today to discuss your specific brazing challenges and discover how KINTEK can support your laboratory's success.

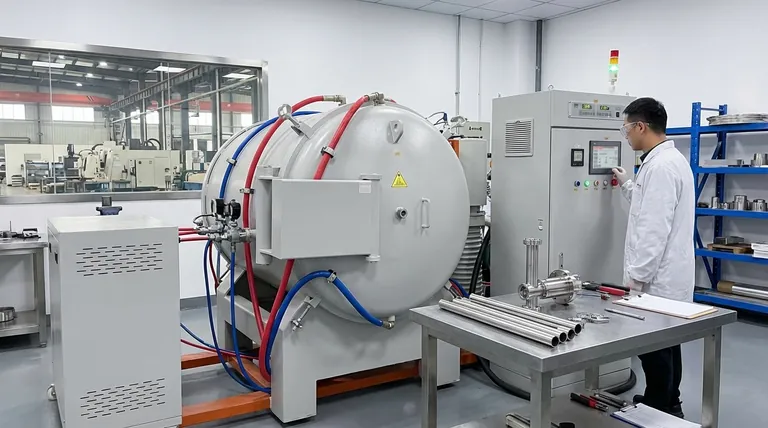

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the temperature stability of graphite? Unlocking Extreme Heat Resistance in the Right Environment

- What is sputter coating? A High-Performance Thin Film Deposition Process

- What is the difference between pyrolysis and incineration? Material Recovery vs. Energy Recovery

- Does THC evaporate over time? The Truth About Potency Loss and Preservation

- Why argon gas is used in sputtering? Achieve Pure, Cost-Effective Thin Film Deposition

- What is film uniformity? The Key to Consistent Device Performance and Yield

- What is a batch type furnace? Achieve Perfect Process Control for Sensitive Applications

- What is the charcoal yield in fast pyrolysis? A Low-Yield Feature for Maximum Bio-Oil