Yes, a primary advantage of vacuum heat treatment is the significant reduction—and often complete elimination—of scaling and decarburization. By conducting the heating process in a near-vacuum, the atmospheric gases like oxygen and carbon dioxide that cause these undesirable surface reactions are removed. This ensures the material's surface integrity is preserved throughout the thermal cycle.

The core value of vacuum heat treatment is its ability to create a chemically inert environment. By removing the atmosphere, you prevent the unwanted chemical reactions of scaling and decarburization from ever occurring, resulting in cleaner, higher-quality parts that require less post-processing.

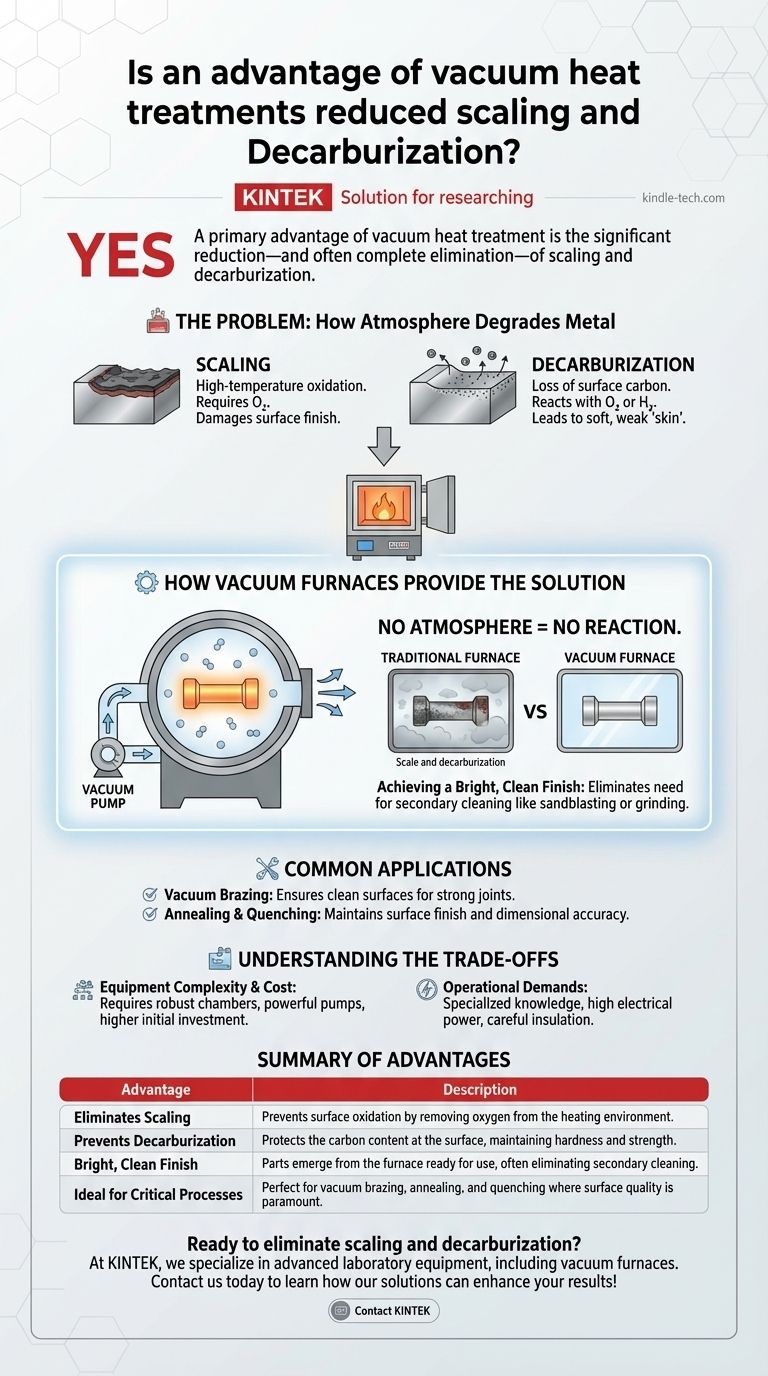

The Problem: How Atmosphere Degrades Metal at High Temperatures

To understand the benefit of a vacuum, we must first understand the problem it solves. When steel and other alloys are heated, they become highly reactive with the gases in the surrounding air.

What is Scaling?

Scaling is simply high-temperature oxidation. It is the formation of a dark, flaky layer of metallic oxides on the surface of a part.

This reaction requires oxygen. The hotter the temperature and the longer the exposure, the thicker the scale becomes, damaging the surface finish and altering the part's dimensions.

What is Decarburization?

Decarburization is the loss of carbon content from the surface layer of steel. This is a critical issue because carbon is the primary element that gives steel its hardness and strength.

This process occurs when carbon atoms near the surface react with gases like oxygen or hydrogen in the furnace atmosphere. The result is a soft, weak outer "skin" on a component that should be hard, leading to premature wear or failure.

How Vacuum Furnaces Provide the Solution

A vacuum furnace directly addresses these issues by removing the root cause: the reactive atmosphere. This approach offers distinct advantages over traditional methods that must carefully control a mixture of gases.

Removing the Reactants

The fundamental principle is simple: no atmosphere, no reaction. By pumping the air out of the heating chamber, the concentration of oxygen and other reactive gases becomes too low to cause significant scaling or decarburization.

The workpiece is heated in a controlled, inert environment, ensuring that the only changes occurring are the intended metallurgical transformations within the material itself.

Achieving a Bright, Clean Finish

The direct result of preventing these surface reactions is a bright, clean part straight out of the furnace.

This is a major benefit, as it often eliminates the need for secondary cleaning operations like sandblasting, chemical pickling, or grinding that are required to remove scale from parts treated in atmosphere furnaces.

Common Applications

This pristine surface finish makes vacuum treatment ideal for a range of processes. It is particularly valuable for vacuum brazing, where perfectly clean surfaces are essential for the brazing alloy to flow and form a strong joint.

It is also the preferred method for processes like annealing and quenching when maintaining the final surface finish and dimensional accuracy is critical.

Understanding the Trade-offs

While vacuum furnaces offer superior results in surface quality, they are not the default solution for every application. It's important to recognize the associated complexities.

Equipment Complexity and Cost

Vacuum furnaces are mechanically complex systems. They require robust chambers to withstand atmospheric pressure, as well as powerful pumping systems to create and maintain the vacuum.

This complexity leads to a higher initial investment cost compared to many traditional atmosphere furnaces.

Operational Demands

Operating a vacuum furnace requires specialized knowledge. The equipment demands significant electrical power, not only for heating but also for the vacuum pumps.

As noted in furnace design, these systems often require low-voltage, high-current power supplies and careful attention to electrical insulation to function safely and effectively under vacuum conditions.

Making the Right Choice for Your Goal

Selecting the correct heat treatment method depends entirely on your project's specific requirements for quality, cost, and volume.

- If your primary focus is the highest possible surface quality: Vacuum heat treatment is the definitive choice, eliminating the risk of scaling and decarburization.

- If your primary focus is processing high-volume, less critical components: A traditional, continuous-belt atmosphere furnace may be more cost-effective.

- If your primary focus is minimizing post-treatment labor: The clean finish from vacuum treatment can significantly reduce or eliminate costly secondary cleaning steps.

Ultimately, choosing vacuum heat treatment is a decision to control the process environment completely, ensuring the final part meets its design intent without compromise.

Summary Table:

| Advantage | Description |

|---|---|

| Eliminates Scaling | Prevents surface oxidation by removing oxygen from the heating environment. |

| Prevents Decarburization | Protects the carbon content at the surface, maintaining hardness and strength. |

| Bright, Clean Finish | Parts emerge from the furnace ready for use, often eliminating secondary cleaning. |

| Ideal for Critical Processes | Perfect for vacuum brazing, annealing, and quenching where surface quality is paramount. |

Ready to eliminate scaling and decarburization from your heat treatment process?

At KINTEK, we specialize in providing advanced laboratory equipment, including vacuum furnaces, designed to meet the stringent demands of modern labs. Our solutions ensure your metal parts achieve a pristine, high-quality finish without costly post-processing.

Contact us today to learn how our vacuum heat treatment equipment can enhance your results and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are annealing applications in industry? Enhance Material Workability and Reliability

- How does temperature affect sintering? Master the Thermal Sweet Spot for Dense, Strong Parts

- What temperature is copper brazing in Celsius? Get the Right Heat for Strong Joints

- Why is a vacuum drying oven necessary for treating WTaVTiZrx powder? Achieve High-Density, Defect-Free Laser Cladding

- Why are high-purity argon and vacuum necessary for 14Cr ODS steel? Essential Protection for Mechanical Alloying

- What type of environment does a high-vacuum bell jar furnace provide? Precision for Plasma Nano-Coatings

- Which type of metals can be melted using tilting furnace? Your Guide to Ferrous, Non-Ferrous & Precious Metals

- What is the process of carburizing? Achieve Superior Surface Hardening with Precision