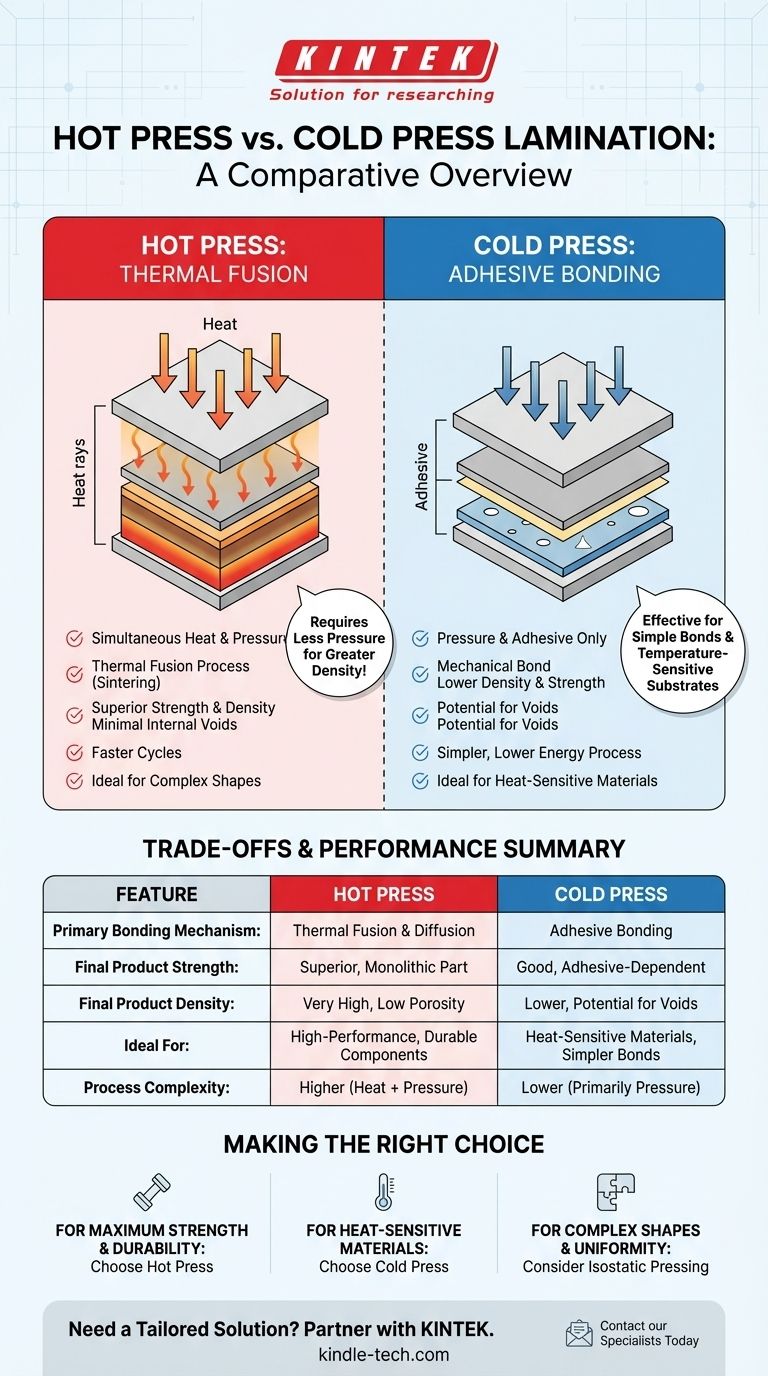

In most industrial applications, hot press lamination produces a stronger, more durable, and higher-density product than cold press methods. The simultaneous application of heat and pressure fundamentally changes the materials, fusing them into a single, unified component rather than simply bonding them with an adhesive.

Hot pressing is not just about gluing materials together; it is a thermal fusion process. It uses controlled heat and pressure to create a superior bond and a denser final product, whereas cold pressing relies primarily on pressure and adhesives.

The Hot Pressing Process: A Deeper Look

Hot pressing is an advanced manufacturing technique where materials are compacted and bonded using both high temperature and significant pressure at the same time. This dual action is the source of its primary advantages.

Simultaneous Heat and Pressure

Unlike cold pressing, which applies pressure at ambient temperature, hot pressing heats the components during compaction. Specialized dies, often made of graphite, are used to effectively distribute this heat throughout the material.

This process essentially makes the material more plastic or malleable. As a result, it requires significantly less force—sometimes as little as one-tenth the pressure of cold pressing—to achieve the desired shape and density.

Fusing Materials at a Microscopic Level

The heat in the hot press process doesn't just soften the material; it promotes mass transfer and diffusion between the layers. This creates a permanent mechanical and electrical connection that is far stronger than a simple adhesive bond.

The result is a sintered body with a fine-grain structure that often approaches the material's theoretical maximum density.

Key Advantages of Hot Pressing

The benefits of hot pressing are directly tied to its use of heat, which unlocks superior material properties and process efficiencies.

Superior Strength and Density

By simultaneously heating and pressurizing, hot pressing minimizes internal voids and creates a highly dense, non-porous final product. This results in components with excellent mechanical properties, including greater strength, rigidity, and resistance to delamination.

Enhanced Process Control and Efficiency

Modern hot press machines offer precise control over temperature and pressure. This allows for rapid heating cycles and consistent temperature distribution, ensuring every part is manufactured to the same high standard.

The process also reduces the required sintering time and temperature compared to other methods, which helps inhibit undesirable grain growth and preserves the material's fine internal structure.

Versatility for Complex Products

Because the material is in a thermoplastic state during pressing, it flows more easily into complex molds. This makes hot pressing ideal for producing intricately shaped or accurately sized products that would be difficult or impossible to achieve with cold pressing alone.

Understanding the Trade-offs: Hot Press vs. Cold Press

Choosing between hot and cold pressing requires understanding the fundamental trade-offs between ultimate performance and process simplicity.

Performance vs. Process Simplicity

Hot pressing is an engineered process designed for high-performance outcomes. It creates a fused, monolithic part with superior strength. This complexity, however, often requires more sophisticated and energy-intensive equipment.

Cold pressing is a simpler mechanical or adhesive process. It's faster for many applications and generally requires less capital investment and energy. Its primary limitation is that the bond is typically adhesive-based, not fused.

Uniformity and Pressure

While hot pressing excels at creating dense parts, certain advanced cold press techniques like isostatic pressing are unmatched for achieving uniform density. Isostatic pressing applies pressure equally from all directions, eliminating the die-wall friction that can cause density variations in other methods.

However, for a given density, hot pressing's use of heat dramatically lowers the required compaction pressure, reducing stress on the equipment and the material itself.

Material Compatibility

The most obvious trade-off is material compatibility. Hot pressing is only suitable for materials that can withstand the high temperatures involved without degrading. For heat-sensitive substrates or components, cold pressing is the only viable option.

Making the Right Choice for Your Goal

The "better" method depends entirely on the performance requirements of the final product and the nature of the materials being used.

- If your primary focus is maximum strength, durability, and density: Hot pressing is the superior choice for its ability to fuse materials into a single, robust part.

- If your primary focus is bonding heat-sensitive materials or cost-effective simplicity: Cold pressing is the more practical and efficient solution.

- If your primary focus is creating complex shapes with the most uniform density possible: Advanced methods like isostatic pressing (which can be hot or cold) should be considered.

Ultimately, your decision should be guided by a clear understanding of your material's properties and the specific application's demands.

Summary Table:

| Feature | Hot Press Lamination | Cold Press Lamination |

|---|---|---|

| Primary Bonding Mechanism | Thermal fusion & diffusion | Adhesive bonding |

| Final Product Strength | Superior, monolithic part | Good, adhesive-dependent |

| Final Product Density | Very high, low porosity | Lower, potential for voids |

| Ideal For | High-performance, durable components | Heat-sensitive materials, simpler bonds |

| Process Complexity | Higher (heat + pressure control) | Lower (primarily pressure) |

Need a Lamination Solution Tailored to Your Materials and Performance Goals?

Choosing the right pressing method is critical to your product's success. The experts at KINTEK can help you navigate the trade-offs between hot and cold press lamination to achieve the perfect balance of strength, durability, and cost-effectiveness for your specific application.

As your partner in laboratory equipment and consumables, we provide the insights and technology to ensure your materials perform as expected.

Contact our specialists today for a personalized consultation and discover the ideal pressing solution for your lab's needs.

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- How does a programmable hot press contribute to the manufacturing of NiO-YSZ anode supports for fuel cells?

- Why is it necessary to integrate a heating device with a laboratory hydraulic press for cold sintering of BZY20?

- How does 40 MPa uniaxial pressure promote TaC densification? Enhance Tantalum Carbide Performance with Hot Pressing

- Do you need silicone paper for heat press? The Essential Guide to Protective Sheets

- What is the core function of a laboratory hot press in PEO electrolytes? Mastering Solvent-Free Densification

- What is the temperature and pressure of hot pressing? Tailoring Parameters for Your Material

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- What role does a benchtop hot press play in densifying composite cathodes? Achieve <10% Porosity with Thermo-Mechanical Flow