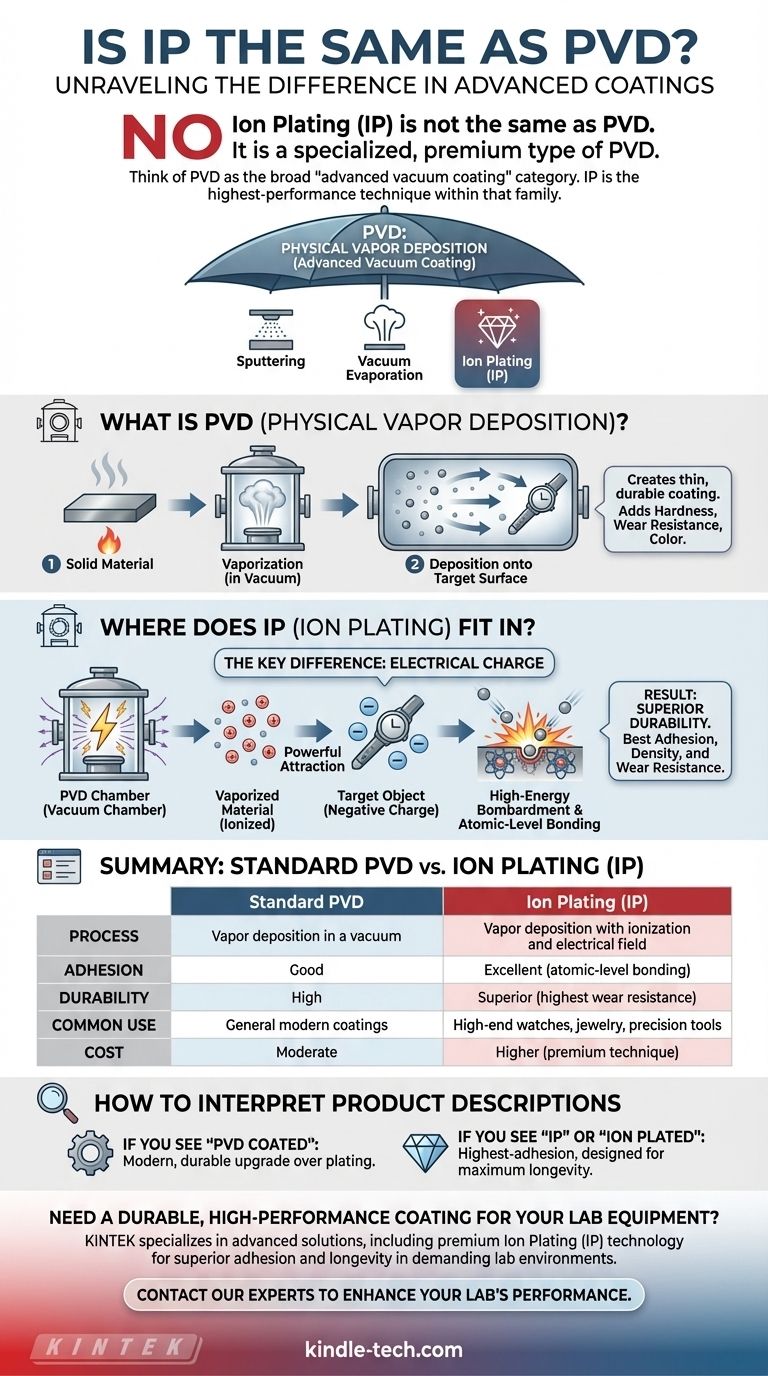

No, Ion Plating (IP) is not the same as PVD. Rather, IP is a specific and advanced type of PVD (Physical Vapor Deposition). PVD is the broad name for a family of modern coating processes, and Ion Plating is widely considered the highest-performance technique within that family.

Think of PVD as the overall category for "advanced vacuum coating." Ion Plating (IP) is a specialized, premium method within that category, distinguished by its use of an electrical charge to create coatings with superior adhesion and durability.

What is PVD (Physical Vapor Deposition)?

The Core Concept

PVD is a process where a solid material is vaporized in a vacuum and deposited onto the surface of a target object. This creates an extremely thin yet highly durable coating.

This process is used to improve the properties of a surface, adding hardness, wear resistance, and color.

A Family of Processes

PVD is not a single technique but an umbrella term that covers several methods. The most common types include sputtering, vacuum evaporation, and Ion Plating (IP).

Each method vaporizes and deposits the material differently, resulting in coatings with varying characteristics.

Where Does IP (Ion Plating) Fit In?

The Key Difference: An Electrical Charge

Ion Plating is a more advanced form of PVD. It enhances the standard process by introducing an electrical field.

This field ionizes the vaporized coating material, giving the particles a positive electrical charge. The object being coated is given a negative charge, creating a powerful attraction.

The Impact of Ionization

This electrical attraction causes the coating particles to accelerate and strike the target object with very high energy.

This high-energy bombardment embeds the coating material into the surface at an atomic level, rather than just layering it on top. This creates an exceptionally strong bond.

The Result: Superior Durability

Because of this intense bonding process, IP is the most durable of the common PVD techniques. It produces a coating with the best adhesion, density, and wear resistance.

Understanding the Practical Trade-offs

"PVD" as a General Label

When a product is simply marked as having a "PVD coating," it often refers to a more standard method like sputtering. This is still a very good, modern coating that is far superior to older methods like electroplating.

However, the term alone doesn't specify the exact level of durability.

"IP" as a Mark of Quality

Manufacturers often specify "Ion Plating" or "IP" when they want to highlight the premium nature and superior longevity of the finish.

You will frequently see this distinction made for high-end watches, premium jewelry, and precision tools where long-term wear is a primary concern.

The Cost Factor

The IP process is more complex and energy-intensive than other PVD methods. This makes it a more expensive technique, which is why it is typically reserved for higher-quality products.

How to Interpret Product Descriptions

When evaluating a product's finish, understanding this hierarchy is key.

- If you see "PVD Coated": This signifies a modern, durable vacuum coating that is a significant upgrade over traditional plating.

- If you see "IP" or "Ion Plated": This indicates one of the most durable and highest-adhesion PVD techniques available, designed for maximum longevity.

Recognizing the difference between the general PVD category and the specific IP process empowers you to better judge the true quality of a finish.

Summary Table:

| Feature | Standard PVD | Ion Plating (IP) |

|---|---|---|

| Process | Vapor deposition in a vacuum | Vapor deposition with ionization and electrical field |

| Adhesion | Good | Excellent (atomic-level bonding) |

| Durability | High | Superior (highest wear resistance) |

| Common Use | General modern coatings | High-end watches, jewelry, precision tools |

| Cost | Moderate | Higher (premium technique) |

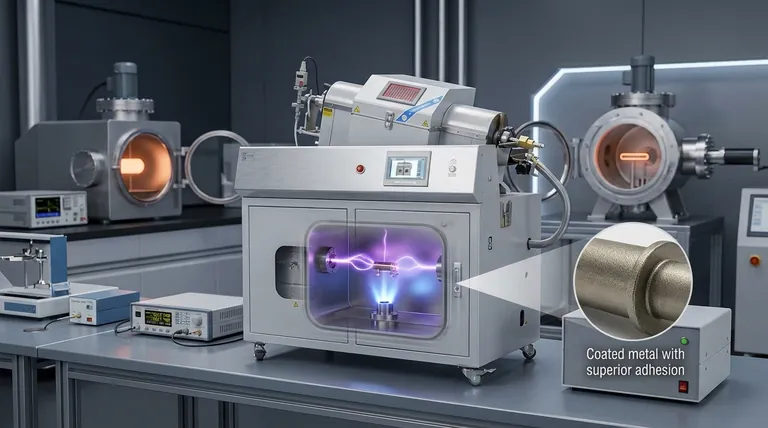

Need a Durable, High-Performance Coating for Your Lab Equipment or Components?

At KINTEK, we specialize in advanced coating solutions, including premium Ion Plating (IP) technology. Our expertise ensures your laboratory equipment and consumables benefit from superior adhesion, wear resistance, and longevity—critical for maintaining precision and reliability in demanding environments.

Let us help you select the ideal coating process for your specific application. Contact our experts today to discuss your project requirements and discover how KINTEK's solutions can enhance your lab's performance.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- How many types of sputtering are there? A Guide to DC, RF, and Advanced Techniques

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained