Yes, molybdenum is considered a good thermal conductor. This property, combined with its exceptionally high melting point and strength at elevated temperatures, makes it a valuable material for specialized industrial applications where heat management under extreme conditions is critical.

The true value of molybdenum is not that it's the best thermal conductor, but that it maintains its structural integrity and good conductivity at temperatures that would cause common conductors like copper or aluminum to fail.

The Role of Molybdenum in High-Temperature Environments

Molybdenum's unique combination of properties makes it a key player in a specific class of materials known as refractory metals. Understanding this context is crucial to appreciating its thermal performance.

A Profile of a Refractory Metal

Molybdenum is a metallic element prized for its resistance to heat and wear. As a refractory metal, its defining characteristic is an extremely high melting point of 2610°C (4730°F).

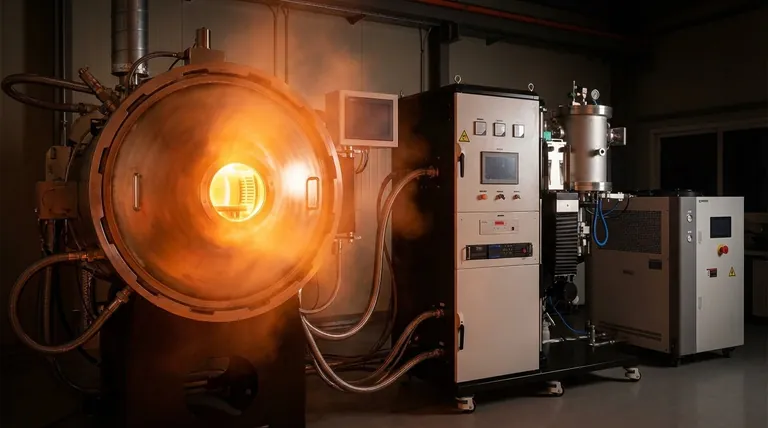

This allows it to be used in demanding environments like vacuum furnaces, where it can operate at temperatures up to 1700°C (3100°F).

Conductivity Where It Counts

While metals like copper are superior thermal conductors at room temperature, their utility plummets as they approach their much lower melting points.

Molybdenum's "good" thermal conductivity is significant because it is present at these extreme operational temperatures, allowing for effective and uniform heat transfer in applications like metal hardening and brazing processes.

Applications Driven by Combined Strengths

Molybdenum is rarely chosen for its conductivity alone. It is selected for its entire profile: high-temperature strength, resistance to deformation, and good thermal and electrical conductivity.

This combination makes it ideal for furnace heating elements, heat shields, and structural furnace components that must remain stable while managing intense heat.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging a material's limitations to ensure it is used correctly.

The Brittleness Threshold

While robust at high temperatures, molybdenum can become brittle when pushed beyond its operational limits (around 1700°C). This defines a clear ceiling for its use in structural applications.

Performance vs. Common Conductors

In applications below a few hundred degrees, molybdenum offers no thermal advantage over common materials. Copper and aluminum are far more effective and cost-efficient conductors for low-to-moderate temperature systems.

Its Primary Role as an Alloy

It's important to note that most molybdenum is not used in its pure form. It is most commonly employed as an alloying element, where it is added to steel to increase strength, hardness, and corrosion resistance at high temperatures.

Making the Right Choice for Your Application

Your material choice should be driven entirely by the operational demands of your project.

- If your primary focus is high-temperature stability and strength with good heat transfer: Molybdenum is an excellent choice for components operating above 1000°C.

- If your primary focus is maximum thermal conductivity at ambient or moderate temperatures: Materials like copper or aluminum are the superior and more economical options.

Ultimately, selecting molybdenum is a decision to prioritize performance and stability in extreme heat over peak conductivity at room temperature.

Summary Table:

| Property | Value / Description |

|---|---|

| Thermal Conductivity | Good, especially at high temperatures |

| Melting Point | 2610°C (4730°F) |

| Key Strength | Maintains conductivity and strength above 1000°C |

| Primary Use | High-temperature furnace elements, heat shields, and alloying |

| Comparison | Outperforms copper/aluminum in extreme heat environments |

Need a reliable thermal solution for extreme temperatures? KINTEK specializes in high-performance lab equipment and consumables, including molybdenum components designed for superior heat management. Our expertise ensures your laboratory operates efficiently and safely, even under the most demanding conditions. Contact us today to discuss how our solutions can meet your high-temperature application needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

People Also Ask

- Why use SiC heating elements for Li2ZrO3-MgO synthesis at 1300°C? Achieve Precise Thermal Stability

- What are the advantages of using tungsten? Achieve Unmatched Performance in Extreme Environments

- What is a sintered element? A Guide to Engineered Porosity and Complex Shapes

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C

- Why does my heating element keep going out? Stop the cycle of failure with these expert solutions.

- How does the combination of thermocouples and temperature control systems affect the study of reduction kinetics?

- What is the operating principle of a resistance wire heater? Insights into Joule Heating and Precise Thermal Control

- Why tungsten is not used in heating devices? The Critical Role of Oxidation Resistance