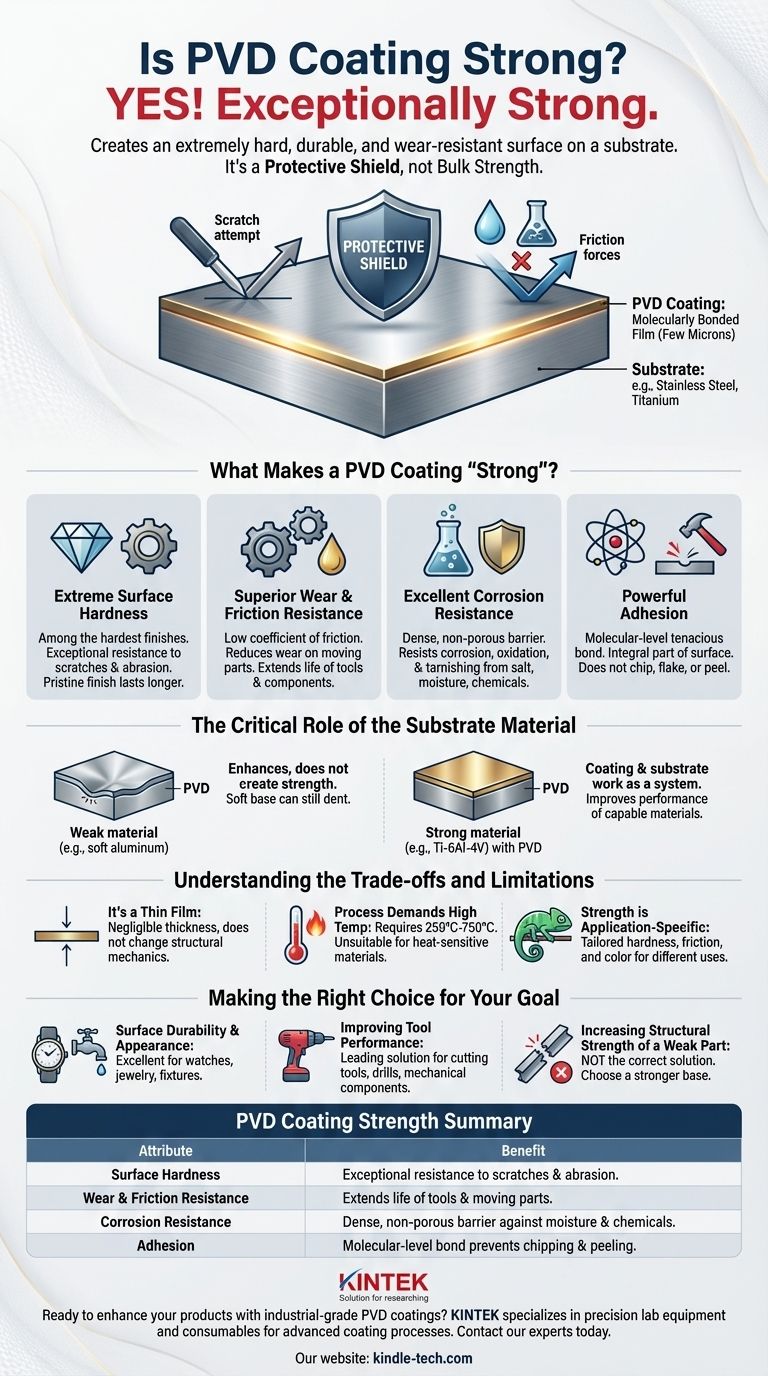

Yes, PVD coating is exceptionally strong. More accurately, it creates an extremely hard, durable, and wear-resistant surface on a substrate material. Rather than adding bulk strength, Physical Vapor Deposition (PVD) forms a thin, molecularly bonded film that acts as a protective shield, drastically improving the surface properties of the underlying object.

PVD does not make a weak object structurally stronger. Instead, it provides a super-hard surface layer that offers unparalleled resistance to scratching, wear, and corrosion, making the surface of the object incredibly durable.

What Makes a PVD Coating "Strong"?

The term "strong" in the context of PVD refers to a specific set of surface characteristics. The process deposits a thin film, typically just a few microns thick, that fundamentally enhances the substrate.

Extreme Surface Hardness

PVD coatings are among the hardest finishes available. This hardness is what provides exceptional resistance to scratches and abrasion, keeping the product's finish looking pristine far longer than traditional methods like painting or plating.

Superior Wear and Friction Resistance

The process can be tailored to create surfaces with a very low coefficient of friction. This reduces the force of wear on moving parts, extending the life of components like cutting tools, engine parts, and mechanical joints.

Excellent Corrosion Resistance

The deposited film is dense and non-porous, forming an inert barrier between the substrate and the environment. This makes PVD-coated items highly resistant to corrosion, oxidation, and tarnishing caused by salt, moisture, and other chemicals.

Powerful Adhesion

PVD is a vacuum deposition process that forms a tenacious bond at the molecular level. Unlike paints or electroplating that can chip, flake, or peel, a PVD coating becomes an integral part of the surface itself.

The Critical Role of the Substrate Material

A PVD coating's performance is fundamentally linked to the material it is applied to. The coating and the substrate work together as a system.

The Coating and Substrate Work as a Team

Think of PVD as a high-performance shield. A shield is most effective when wielded by a strong warrior. Similarly, a PVD coating performs best when applied to a durable substrate like stainless steel, titanium, or other alloys.

PVD Enhances, It Does Not Create Strength

The coating will not prevent a weak or soft base material from denting or deforming. For instance, a hard PVD coating on soft aluminum will still allow the part to dent easily, though the surface itself may not scratch.

Example: Titanium Alloy Enhancement

When a Titanium Nitride (TiN) PVD coating is applied to a Ti-6Al-4V alloy—a strong material in its own right—it measurably improves fatigue limits and endurance. The coating enhances the performance of an already capable material.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Thin Film, Not Bulk Material

PVD adds negligible thickness or weight and does not change the part's structural mechanics. It will not stop a component from bending or breaking if the underlying part is overloaded.

Process Demands High Temperature

The PVD process requires high temperatures, often between 250°C and 750°C. This makes it unsuitable for heat-sensitive materials like most plastics or low-melt-temperature alloys.

Strength is Application-Specific

There is no single "PVD strength." The hardness, friction, and color are all controlled by adjusting the coating material and process parameters. A coating designed for a decorative faucet will have different properties than one designed for an industrial cutting tool.

Making the Right Choice for Your Goal

To determine if PVD is right for you, consider your primary objective.

- If your primary focus is surface durability and appearance: PVD is an excellent choice for preventing scratches, wear, and corrosion on products like watches, jewelry, and architectural fixtures.

- If your primary focus is improving tool performance: PVD is a leading solution for extending the life and efficiency of cutting tools, drills, and mechanical components by increasing hardness and reducing friction.

- If your primary focus is increasing the structural strength of a weak part: PVD is not the correct solution. You must first choose a stronger base material for your component.

Ultimately, PVD provides unparalleled surface protection, making it a definitive choice when applied to the right material for the right job.

Summary Table:

| PVD Coating Strength Attribute | Benefit |

|---|---|

| Surface Hardness | Exceptional resistance to scratches and abrasion. |

| Wear & Friction Resistance | Extends the life of tools and moving parts. |

| Corrosion Resistance | Dense, non-porous barrier against moisture and chemicals. |

| Adhesion | Molecular-level bond prevents chipping and peeling. |

Ready to enhance your products with industrial-grade PVD coatings?

KINTEK specializes in precision lab equipment and consumables for advanced coating processes. Whether you're developing cutting tools, durable components, or high-end consumer goods, our solutions can help you achieve superior surface hardness and longevity.

Contact our experts today to discuss how we can support your laboratory's coating and material enhancement needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings