For years, ceramic coatings have been the gold standard, but the definition of "better" depends entirely on the type of protection you need. In terms of pure physical defense against impacts like rock chips and scratches, Paint Protection Film (PPF) is a superior technology. However, when it comes to chemical resistance and ease of cleaning, ceramic coatings still hold a vital and distinct advantage.

The question is not which product is better, but which one is the right tool for a specific job. PPF offers unparalleled physical armor, while ceramic coatings provide an exceptional chemical shield. The ultimate protection often involves using them together.

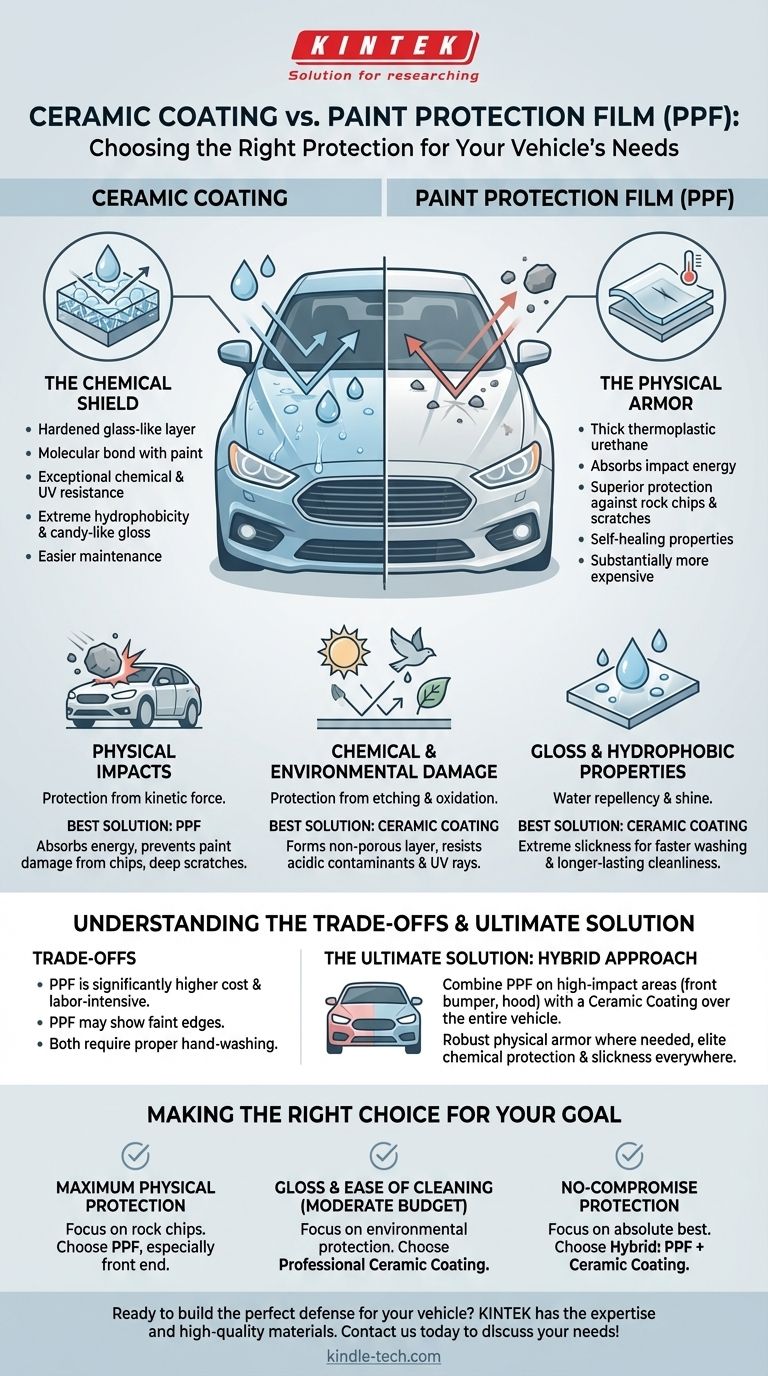

What Defines "Better" in Paint Protection?

To find a solution that's "better" than a ceramic coating, we must first break down the different kinds of protection a vehicle's paint requires. No single product is the master of all of them.

Protection from Physical Impacts

This category includes rock chips, deep scratches, swirl marks from washing, and minor scuffs. This is about defending against kinetic force.

Paint Protection Film (PPF) is the undisputed champion here. It is a thick, transparent, and often self-healing urethane film that physically absorbs the energy from impacts, preventing the paint underneath from being damaged.

Protection from Chemical & Environmental Damage

This covers damage from acidic bird droppings, bug splatter, tree sap, road tar, and harmful UV rays that cause paint to oxidize and fade.

Ceramic coatings excel in this area. A coating forms a molecular bond with your paint, creating a hardened, non-porous layer that is highly resistant to chemical etching and UV degradation.

Gloss and Hydrophobic Properties

"Hydrophobic" refers to a surface's ability to repel water, causing it to bead up and slide off easily. This property makes washing the car significantly faster and helps it stay cleaner for longer.

While both products enhance gloss, ceramic coatings are specifically engineered for extreme hydrophobicity. This slickness is the primary reason coated cars are so effortless to maintain.

A Head-to-Head Comparison: Coating vs. PPF

Think of these two products as specialized members of a team, each with a unique role.

Ceramic Coatings: The Chemical Shield

A ceramic coating is a liquid polymer (typically based on silicon dioxide, or SiO₂) that is professionally applied to a vehicle's exterior. Once cured, it creates a permanent or semi-permanent bond with the paint.

Its core strength is creating a sacrificial, hardened glass-like layer. This shield provides exceptional resistance to chemicals, contaminants, and UV rays, while delivering a deep, candy-like gloss.

Paint Protection Film (PPF): The Physical Armor

PPF is a thermoplastic urethane film, sometimes called a "clear bra." It's best analogized as a heavy-duty, invisible screen protector for your car's paint.

Its defining characteristic is its thickness and ability to absorb impact. Modern, high-quality PPF also has "self-healing" properties, where light scratches and swirl marks disappear with the application of heat from the sun or warm water.

Understanding the Trade-offs

Choosing the right protection involves weighing performance against cost and maintenance realities.

The Cost Factor

This is the most significant difference. A professional ceramic coating is a considerable investment, but PPF is substantially more expensive.

Applying PPF is a highly skilled, labor-intensive process. A full-vehicle PPF installation can easily cost three to five times more than a professional ceramic coating application.

The "Invisible" Reality of PPF

While modern PPF is remarkably clear, it is not truly invisible upon close inspection. You may notice faint edges or seams where the film ends, especially on complex body panels or lighter-colored vehicles.

Maintenance Is Still Required

Neither solution makes your car invincible or maintenance-free. Both require proper hand-washing techniques. Using an automatic car wash with abrasive brushes can still scratch PPF and can clog the pores of a ceramic coating, diminishing its hydrophobic properties.

The Ultimate Solution: Combining PPF and Ceramic Coating

For those seeking the absolute best, no-compromise solution, the answer isn't choosing one over the other—it's using them in tandem.

The Best of Both Worlds

This hybrid approach leverages the unique strengths of each product. PPF is applied to high-impact areas for physical armor, and then a ceramic coating is applied over the entire vehicle, including the PPF.

The coating acts as a protective, hydrophobic top layer for the PPF, shielding it from contaminants and UV damage while making the entire car uniformly easy to wash.

Common Application Strategies

A popular and cost-effective strategy is to apply PPF only to the most vulnerable areas of the car. This typically includes the full front bumper, the hood, front fenders, and side mirrors.

The rest of the car and the newly installed PPF then receive a full ceramic coating application. This delivers robust physical protection where it's needed most and elite chemical protection and slickness everywhere else.

Making the Right Choice for Your Goal

The best paint protection strategy is the one that aligns with your specific goals, driving habits, and budget.

- If your primary focus is maximum protection against rock chips and physical damage: PPF is the superior choice, especially for the front end of your vehicle.

- If your primary focus is exceptional gloss, environmental protection, and ease of cleaning on a moderate budget: A professional-grade ceramic coating offers incredible value and performance.

- If your primary focus is achieving the absolute best, no-compromise protection available: Combining PPF on high-impact areas with a ceramic coating over the entire vehicle is the definitive solution.

Ultimately, understanding the distinct roles of each technology empowers you to build the right defense for your vehicle.

Summary Table:

| Protection Type | Best Solution | Key Benefit |

|---|---|---|

| Physical Impacts (rock chips, scratches) | Paint Protection Film (PPF) | Thick, self-healing film absorbs impact energy. |

| Chemical & Environmental Damage (bird droppings, UV rays) | Ceramic Coating | Hardened, non-porous layer resists etching and fading. |

| Gloss & Ease of Cleaning | Ceramic Coating | Extreme hydrophobicity repels water and contaminants. |

Ready to build the perfect defense for your vehicle? Whether you need the physical armor of PPF, the chemical shield of a ceramic coating, or the ultimate hybrid solution, KINTEK has the expertise and high-quality materials to protect your investment. Our specialized lab equipment and consumables ensure professional-grade results. Contact us today to discuss your specific needs and get a tailored protection plan!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom CVD Diamond Coating for Lab Applications

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

People Also Ask

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- What is the thermal expansion of SiC? Master Its Low CTE for Superior High-Temp Performance

- What are the properties and applications of silicon carbide ceramics? Solve Extreme Engineering Challenges