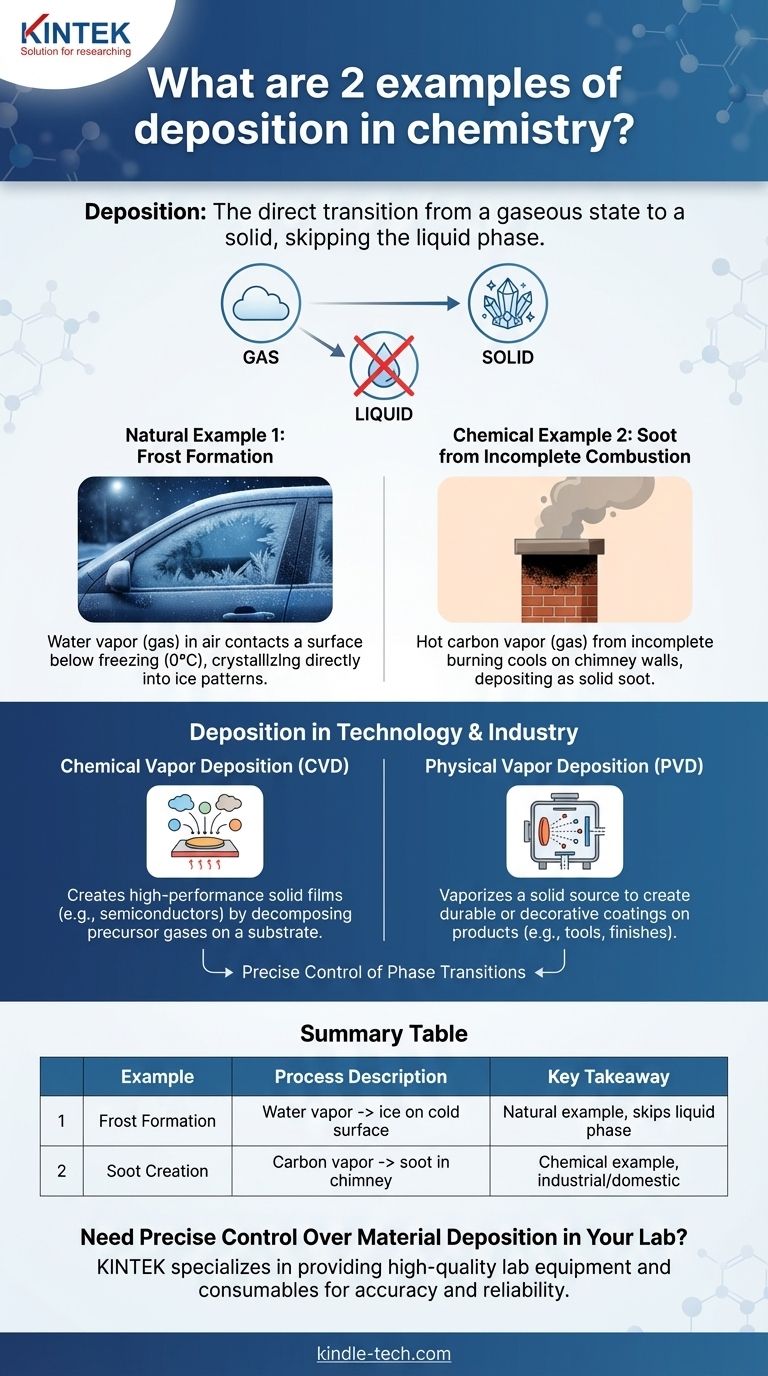

Two clear examples of deposition are the formation of frost on a cold window and the creation of soot in a chimney. In both cases, a substance in a gaseous state turns directly into a solid, completely skipping the intermediate liquid phase. This occurs when gas molecules rapidly lose energy upon contacting a cold surface, causing them to lock into a solid structure.

Deposition is a fundamental phase transition where matter changes directly from a gas to a solid. It is the reverse process of sublimation and is governed by specific conditions of temperature and pressure, playing a crucial role in both natural weather patterns and advanced industrial manufacturing.

What is Deposition? A Deeper Look

The Gas-to-Solid Transition

Deposition is a thermodynamic process. It stands in contrast to the more familiar process of condensation, where a gas turns into a liquid (like water droplets on a cold glass).

Instead of condensing, the gas molecules bypass the liquid state entirely. This direct jump from a high-energy gas phase to a low-energy, ordered solid phase is what defines deposition.

The Role of Thermal Energy

This transition happens when a gas cools rapidly below its freezing point. The molecules lose thermal energy so quickly that they do not have time to form the loosely bonded structure of a liquid.

Instead, they immediately arrange themselves into a fixed, crystalline lattice, characteristic of a solid. Pressure also plays a key role, but a significant drop in temperature is the most common trigger.

Sublimation: The Reverse Process

To fully grasp deposition, it is helpful to understand its opposite: sublimation. This is the process where a solid turns directly into a gas, again skipping the liquid phase.

A common example of sublimation is dry ice (solid carbon dioxide) turning into a cloud of CO2 gas at room temperature. Deposition and sublimation are two sides of the same coin, representing the direct exchange between the solid and gas states.

Analyzing the Examples

Example 1: The Formation of Frost

Frost is a perfect natural example of deposition. It is not frozen dew.

When the temperature of a surface, like a car windshield or a blade of grass, drops below the freezing point of water (0°C or 32°F), deposition can occur. Water vapor (a gas) in the surrounding air comes into direct contact with this cold surface.

The water vapor molecules instantly lose their energy and crystallize into ice. The intricate, feathery patterns of frost are the direct result of these ice crystals forming from a gas.

Example 2: Soot from Incomplete Combustion

Soot formation is a chemical example of deposition. During the incomplete burning of hydrocarbons, like wood or fossil fuels, tiny carbon particles are created and carried in hot gas.

As these hot gases travel up a chimney or exhaust pipe, they cool down upon contact with the cooler surfaces. The carbon vapor deposits directly onto these surfaces as a black, powdery solid we know as soot, without ever becoming liquid carbon.

Deposition in Technology and Industry

Chemical Vapor Deposition (CVD)

In the technology sector, deposition is a highly controlled and essential process. Chemical Vapor Deposition (CVD) is a technique used to create ultra-pure, high-performance solid films.

In CVD, precursor gases are introduced into a reaction chamber. These gases decompose on a heated substrate, causing a solid material to deposit and form a thin, uniform layer. This process is critical for manufacturing semiconductors, optical coatings, and synthetic diamonds.

Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD) is another industrial technique that relies on this principle. A solid source material is vaporized in a vacuum chamber, often by bombarding it with ions (a process called sputtering).

This vapor then travels and deposits onto the surface of a product, creating a durable and often decorative coating. PVD is used for putting hard coatings on cutting tools, wear-resistant films on engine parts, and metallic finishes on plastics.

Key Takeaways for Different Contexts

- If your primary focus is understanding natural phenomena: Recognize deposition as the process that forms frost and snow, where water vapor in the air crystallizes directly into ice without first becoming rain or dew.

- If your primary focus is chemistry and manufacturing: View deposition as a powerful technique (like CVD and PVD) for building materials layer by layer, enabling the creation of advanced electronics and durable coatings.

Ultimately, deposition is the direct pathway from the disordered chaos of a gas to the ordered structure of a solid.

Summary Table:

| Example | Process Description | Key Takeaway |

|---|---|---|

| Frost Formation | Water vapor in air turns directly into ice crystals on a cold surface. | A natural example of deposition, skipping the liquid phase. |

| Soot Creation | Carbon vapor from incomplete combustion deposits as solid soot in a chimney. | A chemical example common in industrial and domestic settings. |

Need Precise Control Over Material Deposition in Your Lab?

From fundamental research to advanced manufacturing processes like CVD and PVD, precise control over phase transitions is critical. KINTEK specializes in providing high-quality lab equipment and consumables that ensure accuracy and reliability in your experiments.

Contact our experts today to find the perfect solution for your laboratory's deposition and material science needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is a natural sintering? Uncover the Geological Process That Forms Ore Deposits

- What is the difference between heating and sintering? Master Material Transformation for Manufacturing

- What is the problem in heat treatment process? The High Cost of Preventing Surface Defects

- How does a magnetic stirrer influence the efficiency of the sulfuric acid leaching process for zinc ash? Expert Insights

- How is a constant temperature drying oven utilized in the determination of pulp yield? Ensure Precision in Biomass Data

- Why is precise temperature control critical for ferritization products? Ensure material stability and performance.

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What is the maximum pressure for a filter press? Choosing the Right PSI for Your Process