In short, batch furnaces are best used for processes requiring high flexibility, precision control, and the ability to handle diverse loads with varying thermal profiles. They excel in applications from specialized metal heat treatment to precise laboratory research, where the process requirements change from one load to the next.

The core advantage of a batch furnace is not high-volume output, but rather its unparalleled process adaptability. You choose a batch furnace when the specific requirements of each individual load—its temperature, duration, and atmosphere—are more critical than the speed of production.

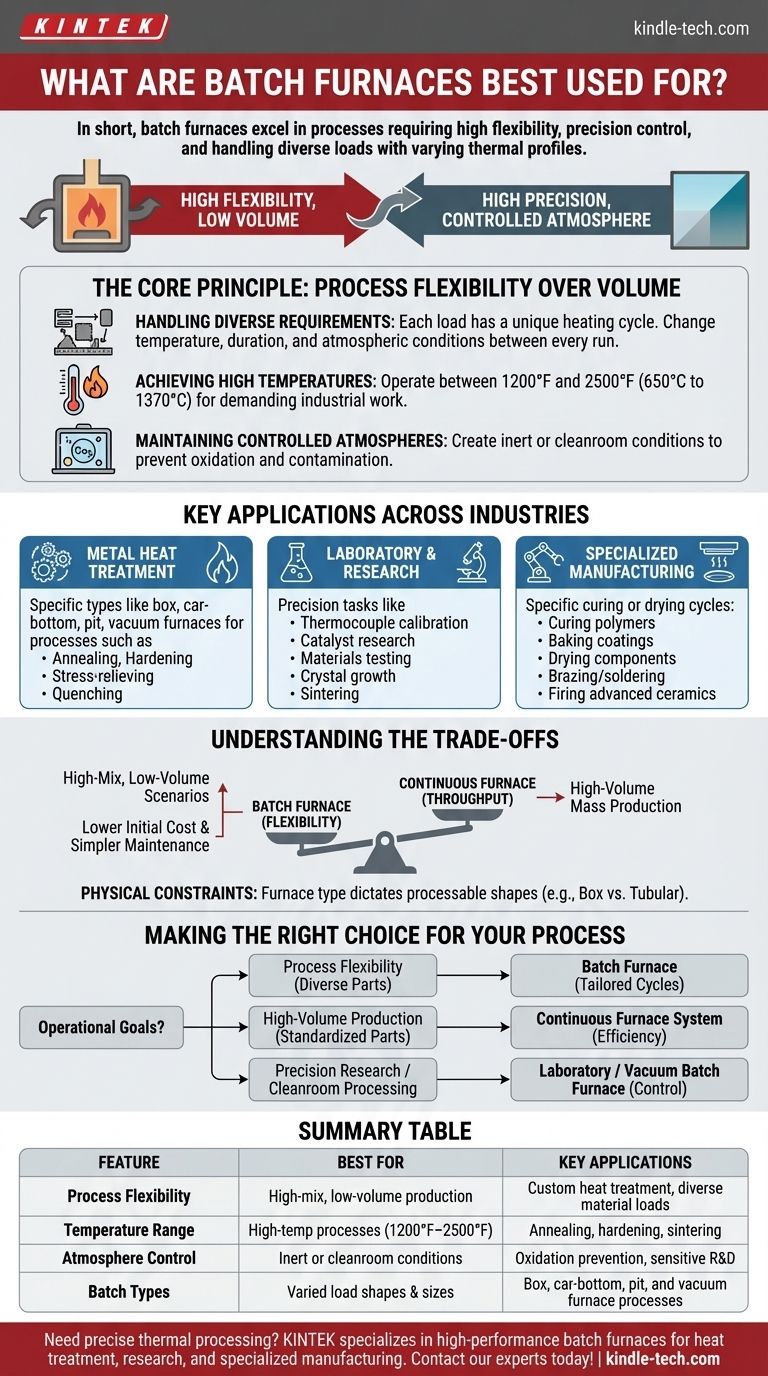

The Core Principle: Process Flexibility Over Volume

The defining characteristic of a batch furnace is its ability to process materials one distinct load, or "batch," at a time. This fundamental design choice creates a system optimized for control and customization rather than continuous throughput.

Handling Diverse Requirements

Each batch can be subjected to a unique heating cycle. You can change the temperature, duration, and atmospheric conditions between every single run. This is essential for facilities that handle a wide variety of parts or research protocols.

Achieving High Temperatures

Batch furnaces are engineered to reach the high temperatures necessary for demanding industrial work. They commonly operate between 1200°F and 2500°F (650°C to 1370°C), making them suitable for treating a wide range of metals and materials.

Maintaining Controlled Atmospheres

Many advanced processes cannot be performed in ambient air. Batch furnaces are particularly well-suited for creating inert atmospheres or cleanroom-level conditions, preventing oxidation and contamination during sensitive heating cycles.

Key Applications Across Industries

The flexibility of batch furnaces makes them essential tools in several distinct sectors. Their application is determined by the need for precise thermal control over a specific, contained load.

Metal Heat Treatment

This is a primary application for industrial batch furnaces. They are used for a variety of processes that alter the physical and chemical properties of metals.

Specific furnace types like box, car-bottom, pit, and vacuum furnaces are used for treatments such as annealing, hardening, stress-relieving, and quenching.

Laboratory and Research Settings

In scientific and R&D environments, precision is paramount. Laboratory chamber and tube furnaces are used for a vast array of small-scale, highly controlled tasks.

These include thermocouple calibration, catalyst research, materials testing, crystal growth, and sintering new material compositions.

Specialized Manufacturing Processes

Beyond metallurgy and research, batch furnaces are vital for manufacturing processes that require specific, timed curing or drying cycles.

Common applications include curing polymers, baking coatings, drying components, brazing/soldering, and firing advanced ceramics.

Understanding the Trade-offs

Choosing a batch furnace involves a clear understanding of its strengths and limitations compared to other heating systems.

Flexibility vs. Throughput

The most significant trade-off is volume. Batch processing is inherently slower for mass production than a continuous furnace, which moves products through on a conveyor. Batch furnaces are for high-mix, low-volume scenarios.

Cost and Complexity

Generally, batch furnaces are less complex mechanically than large continuous systems. This often translates to a lower initial investment and simpler, less expensive long-term maintenance.

Physical and Shape Constraints

The type of batch furnace dictates what it can process. A box furnace is highly versatile for various shapes, while a tubular furnace is specifically designed for elongated items like shafts, strips, or tubes.

Making the Right Choice for Your Process

Selecting the correct heating technology depends entirely on your operational goals.

- If your primary focus is process flexibility for diverse parts: A batch furnace is the ideal choice, allowing you to tailor each heating cycle to the specific load.

- If your primary focus is high-volume production of standardized parts: A continuous furnace system will provide the efficiency and throughput you need.

- If your primary focus is precision research or cleanroom-grade processing: A laboratory or vacuum batch furnace offers the necessary control over temperature and atmosphere.

Ultimately, a batch furnace is the definitive tool for when the integrity of the process outweighs the speed of production.

Summary Table:

| Feature | Best For | Key Applications |

|---|---|---|

| Process Flexibility | High-mix, low-volume production | Custom heat treatment, diverse material loads |

| Temperature Range | High-temp processes (1200°F–2500°F) | Annealing, hardening, sintering |

| Atmosphere Control | Inert or cleanroom conditions | Oxidation prevention, sensitive R&D |

| Batch Types | Varied load shapes & sizes | Box, car-bottom, pit, and vacuum furnace processes |

Need precise thermal processing for your diverse lab or production needs? KINTEK specializes in high-performance batch furnaces designed for unmatched flexibility and control in heat treatment, research, and specialized manufacturing. Our equipment ensures exact temperature and atmosphere management for your most critical applications. Contact our experts today to find the perfect batch furnace solution for your unique requirements!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.