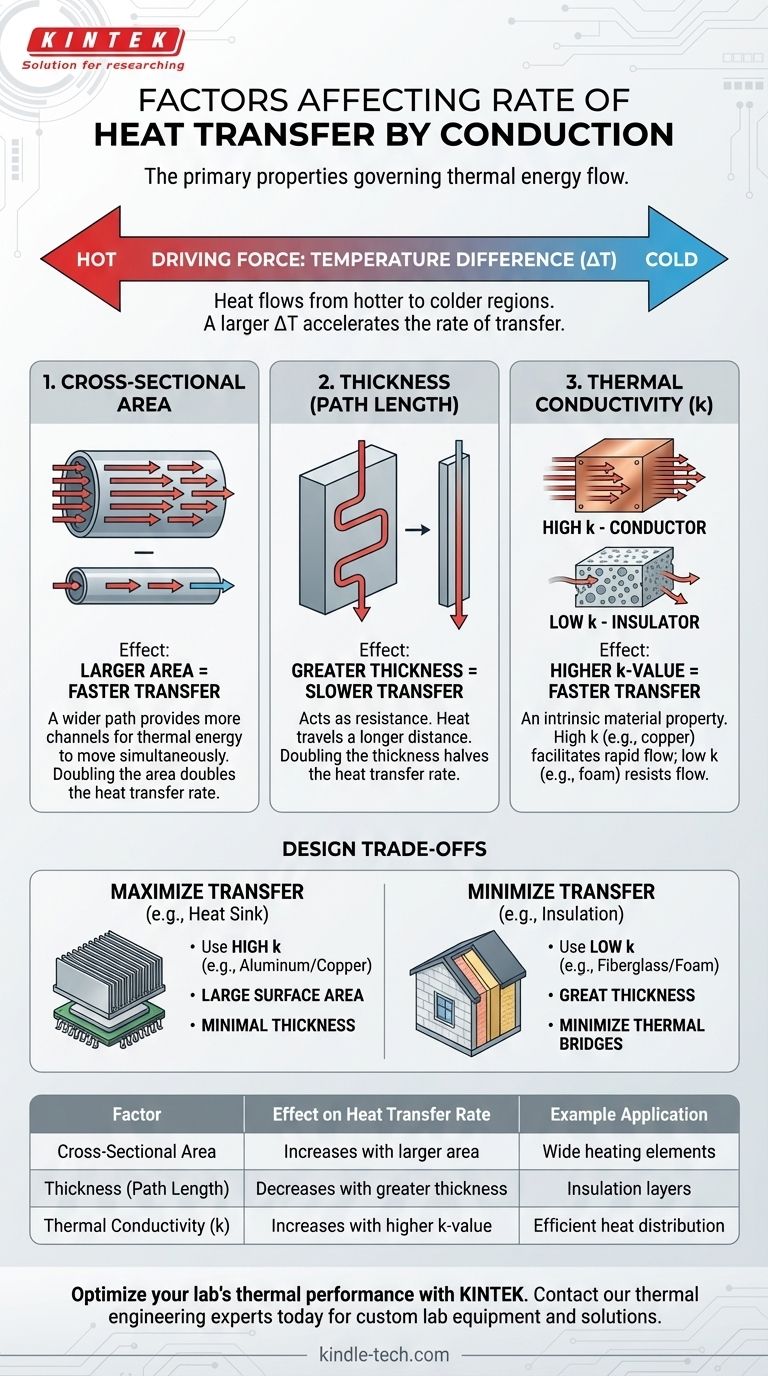

In practice, the rate of heat transfer by conduction is governed by three primary physical and material properties: the cross-sectional area available for heat flow, the thickness or length of the material the heat must travel through, and the material's intrinsic thermal conductivity. A fourth factor, the temperature difference across the material, acts as the fundamental driving force for the entire process.

The core principle is this: heat transfer is a rate of flow. This flow is driven by a temperature difference and is either facilitated or resisted by the geometry (area and thickness) and the inherent properties (thermal conductivity) of the material it passes through.

The Core Principle: The Driving Force of Heat Transfer

Before examining the three material factors, we must acknowledge the engine of conduction: the temperature difference. Without it, no heat transfer occurs.

The Role of Temperature Difference (ΔT)

Think of temperature difference as the "pressure" that pushes thermal energy from a hotter region to a colder one. A larger difference in temperature creates a steeper gradient, resulting in a faster rate of heat transfer.

If two objects are at the same temperature (thermal equilibrium), there is no net flow of heat between them, regardless of the material's properties.

The Three Factors That Modulate Heat Flow

Once a temperature difference exists, the following three factors determine how quickly that heat will flow through the material.

Factor 1: Cross-Sectional Area

The cross-sectional area is the surface area through which the heat is traveling, perpendicular to the direction of flow.

A larger area provides more parallel paths for thermal energy to move. Think of it like a highway: a five-lane highway can handle significantly more traffic (heat) than a single-lane road in the same amount of time.

Therefore, doubling the area doubles the rate of heat transfer, assuming all other factors remain constant.

Factor 2: Thickness (Path Length)

The thickness of the material is the distance the heat must travel from the hot side to the cold side.

This distance acts as resistance. The farther the heat has to travel, the slower the rate of transfer. A thicker wall provides more insulation than a thin one.

Consequently, doubling the thickness of the material halves the rate of heat transfer, as you have doubled the resistance path.

Factor 3: Thermal Conductivity (k)

Thermal conductivity (k) is an intrinsic property of a material that measures its ability to conduct heat.

Materials with high thermal conductivity, like copper and aluminum, are conductors. They transfer heat quickly and efficiently. Materials with low thermal conductivity, like wood, foam, or air, are insulators. They resist the flow of heat.

A material with a high k-value is like a smooth, wide superhighway for heat, while a material with a low k-value is like a bumpy, narrow dirt path.

Understanding the Trade-offs in Design

Understanding these factors allows you to intentionally design systems that either promote or prevent heat transfer.

Maximizing Heat Transfer (e.g., a Heat Sink)

To pull heat away from a component like a computer processor, you would design a heat sink to maximize the rate of conduction.

This means using a material with high thermal conductivity (like aluminum or copper), designing for a large surface area (the reason for all the fins), and ensuring the path length from the heat source to the fins is as short as possible.

Minimizing Heat Transfer (e.g., Insulation)

To keep a house warm in the winter, you need to minimize heat loss through the walls.

This requires using materials with low thermal conductivity (fiberglass or foam insulation), designing for a great thickness (thick layers of insulation), and minimizing any areas of direct connection, or "thermal bridges," that would provide a path for heat to escape.

Making the Right Choice for Your Goal

Your engineering or design goal determines how you manipulate these three factors.

- If your primary focus is rapid cooling or heating: Use a material with high thermal conductivity (like metal) and design for a large cross-sectional area and minimal thickness.

- If your primary focus is thermal insulation: Use a material with low thermal conductivity (like foam, fiberglass, or a vacuum) and design it to be as thick as practical for the application.

Mastering these factors gives you direct control over the flow of thermal energy in any system you design.

Summary Table:

| Factor | Effect on Heat Transfer Rate | Example Application |

|---|---|---|

| Cross-Sectional Area | Increases with larger area | Wide heating elements for uniform heating |

| Thickness (Path Length) | Decreases with greater thickness | Insulation layers to prevent heat loss |

| Thermal Conductivity (k) | Increases with higher k-value | Copper parts for efficient heat distribution |

Optimize your lab's thermal performance with KINTEK.

Whether you need a furnace that heats uniformly, a reactor that maintains precise temperatures, or custom equipment designed for maximum energy efficiency, our expertise in thermal dynamics ensures your lab operates at peak performance. We provide durable, reliable lab equipment and consumables tailored to your specific research needs.

Contact our thermal engineering experts today to discuss how we can help you achieve superior control over heat transfer in your laboratory.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a muffle furnace in the environment? Achieve Clean, Contaminant-Free Heating

- What is the heat capacity of a muffle furnace? Understanding Thermal Mass for Optimal Performance

- How does a muffle oven work? Achieve Pure, Contamination-Free Heating for Your Lab

- What is the difference between an oven and a muffle? Choose the Right Heating Tool for Your Lab

- What is the difference between a muffle furnace and a drying oven? Choose the Right Thermal Tool