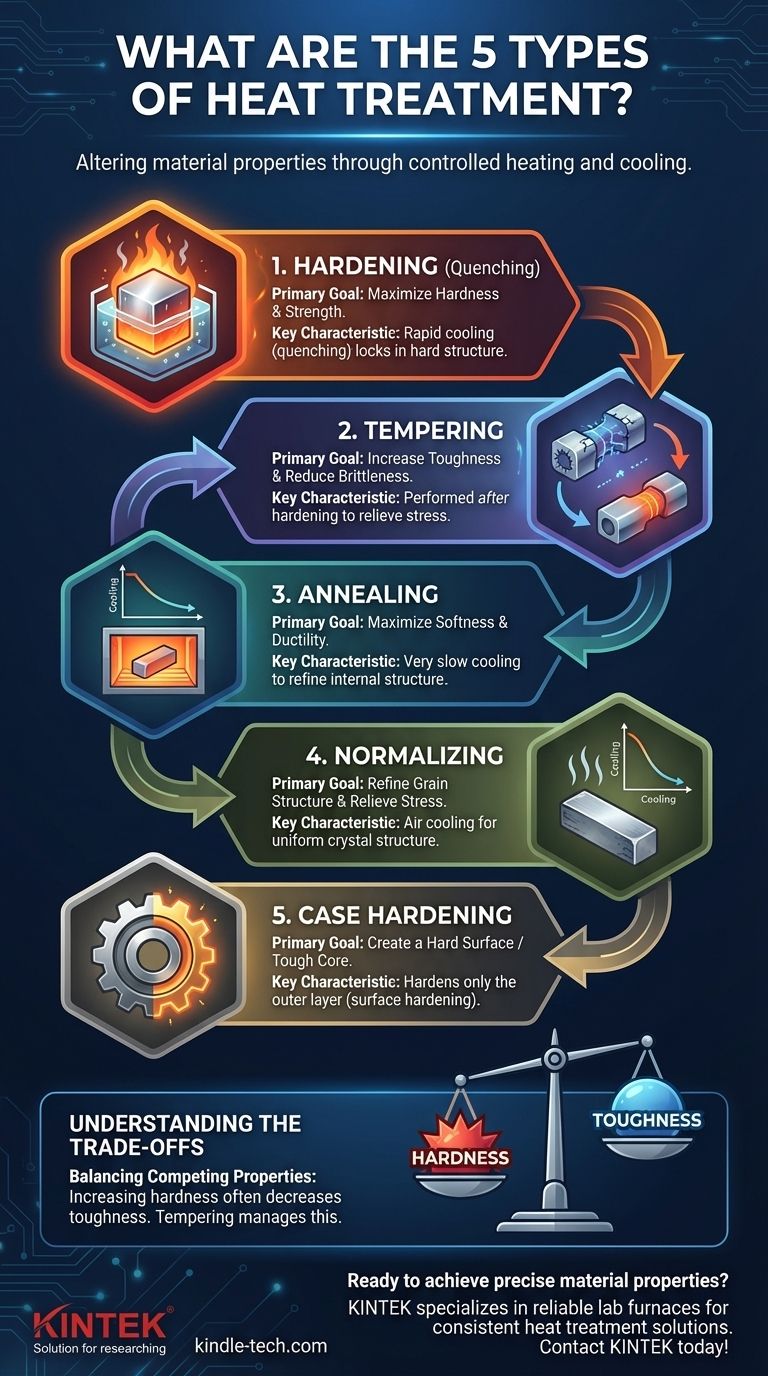

Ultimately, there are five fundamental types of heat treatment processes. While many specific techniques exist, they all fall into the primary categories of hardening, tempering, annealing, normalizing, and case hardening. Each process involves a carefully controlled cycle of heating and cooling designed to manipulate a metal's internal structure to achieve a desired mechanical property.

The core purpose of any heat treatment is to intentionally alter a material's physical properties. By controlling temperature and cooling rates, you can change the microscopic crystal structure of a metal, making it harder, softer, tougher, or more resistant to wear.

Why We Use Heat Treatment

The primary goal of heat treatment is to change a material's mechanical characteristics to better suit a specific application. This is a critical step in manufacturing, especially for steel parts.

Improving Material Properties

Heat treatment can increase a material's strength, hardness, and wear resistance. This is essential for components like cutting tools, bearings, and gears that must withstand significant stress and friction.

Enhancing Workability

Conversely, some processes make materials softer and more ductile. This relieves internal stresses created during manufacturing, making the part easier to machine, form, or weld without cracking.

Increasing Toughness

A key benefit is improving a material's toughness, which is its ability to absorb energy and resist fracturing. This is often a balancing act, as increasing hardness can sometimes make a material more brittle.

The Five Foundational Heat Treatment Processes

Each of the five main processes uses a unique heating and cooling profile to produce a specific outcome.

1. Hardening

Hardening, also known as quenching, is designed to maximize a metal's hardness and strength. The process involves heating steel to a critical temperature where its crystal structure changes, then cooling it very rapidly by plunging it into a medium like water, oil, or air.

This rapid cooling, or quenching, locks the hard crystal structure in place.

2. Tempering

A hardened part is often extremely brittle and contains significant internal stress. Tempering is a secondary process performed after hardening to address this.

The part is reheated to a much lower temperature and held for a specific time. This process reduces brittleness and relieves stress, resulting in a tougher, more durable component.

3. Annealing

Annealing is essentially the opposite of hardening. The goal is to make a metal as soft and ductile as possible.

The material is heated to a specific temperature and then cooled very slowly, often by leaving it inside the furnace as it cools. This produces a refined internal structure that is easy to machine and form.

4. Normalizing

Normalizing is often confused with annealing but serves a distinct purpose. It also involves heating the metal, but the cooling rate is faster—typically by letting it cool in still air.

This process creates a more uniform and fine-grained crystal structure. The result is a material that is stronger and harder than an annealed part but not as hard as a quenched part. It is often used to refine the grain structure and relieve stress from prior operations.

5. Case Hardening

Case hardening, or surface hardening, is a category of processes that hardens only the outer surface of a part while leaving the inner core soft and tough.

This creates a component with a wear-resistant exterior and a ductile interior that can absorb shock and impact. It is the ideal treatment for parts like gears, camshafts, and bearings.

Understanding the Trade-offs

No single heat treatment process is perfect for every application. The primary challenge is balancing competing properties, and failure to control the process can lead to ruined parts.

Hardness vs. Toughness

The most critical trade-off in metallurgy is between hardness and toughness. As you increase a material's hardness, you almost always decrease its toughness, making it more brittle and prone to fracture.

Tempering is the classic example of managing this trade-off, as it sacrifices some hardness to gain essential toughness.

Distortion and Cracking

The rapid heating and cooling cycles involved in heat treatment cause metals to expand and contract. If not managed carefully, this can lead to warping, distortion, or even cracking of the part.

Proper support in the furnace and selection of the correct quenching medium are critical to minimizing these risks.

Making the Right Choice for Your Goal

Selecting the correct heat treatment depends entirely on the final application of the component.

- If your primary focus is maximum hardness and wear resistance: Your path is hardening (quenching) followed by a low-temperature temper to relieve stress.

- If your primary focus is improving machinability or formability: Annealing is the correct choice to make the material as soft and ductile as possible.

- If your primary focus is a tough, impact-resistant core with a wear-resistant surface: Case hardening is the definitive solution for components like gears and shafts.

- If your primary focus is creating a uniform grain structure and relieving stress: Normalizing provides a predictable and consistent material state, often as a preliminary step for other treatments.

Understanding these foundational processes empowers you to precisely control the final performance of your materials.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Hardening | Maximize Hardness & Strength | Rapid cooling (quenching) |

| Tempering | Increase Toughness & Reduce Brittleness | Performed after hardening |

| Annealing | Maximize Softness & Ductility | Very slow cooling |

| Normalizing | Refine Grain Structure & Relieve Stress | Air cooling |

| Case Hardening | Create a Hard Surface / Tough Core | Hardens only the outer layer |

Ready to achieve precise material properties in your lab? The right heat treatment is key to enhancing strength, toughness, and durability. KINTEK specializes in providing the reliable lab furnaces and equipment needed for consistent hardening, tempering, annealing, and more. Let our experts help you select the perfect solution for your laboratory's specific material science challenges.

Contact KINTEK today to discuss your heat treatment needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- How does heat treatment process work? Tailor Material Properties for Your Application

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity