In essence, transfer moulding offers a significant step up in precision and design complexity compared to compression moulding, particularly for parts with delicate inserts. However, these advantages come at the cost of higher tooling investment and unavoidable material waste, making it a strategic choice for specific applications rather than a universal solution.

Transfer moulding occupies a critical middle ground between the simplicity of compression moulding and the high-volume speed of injection moulding. Its core value lies in its ability to produce intricate, dimensionally stable thermoset parts that are difficult or impossible to create with other methods.

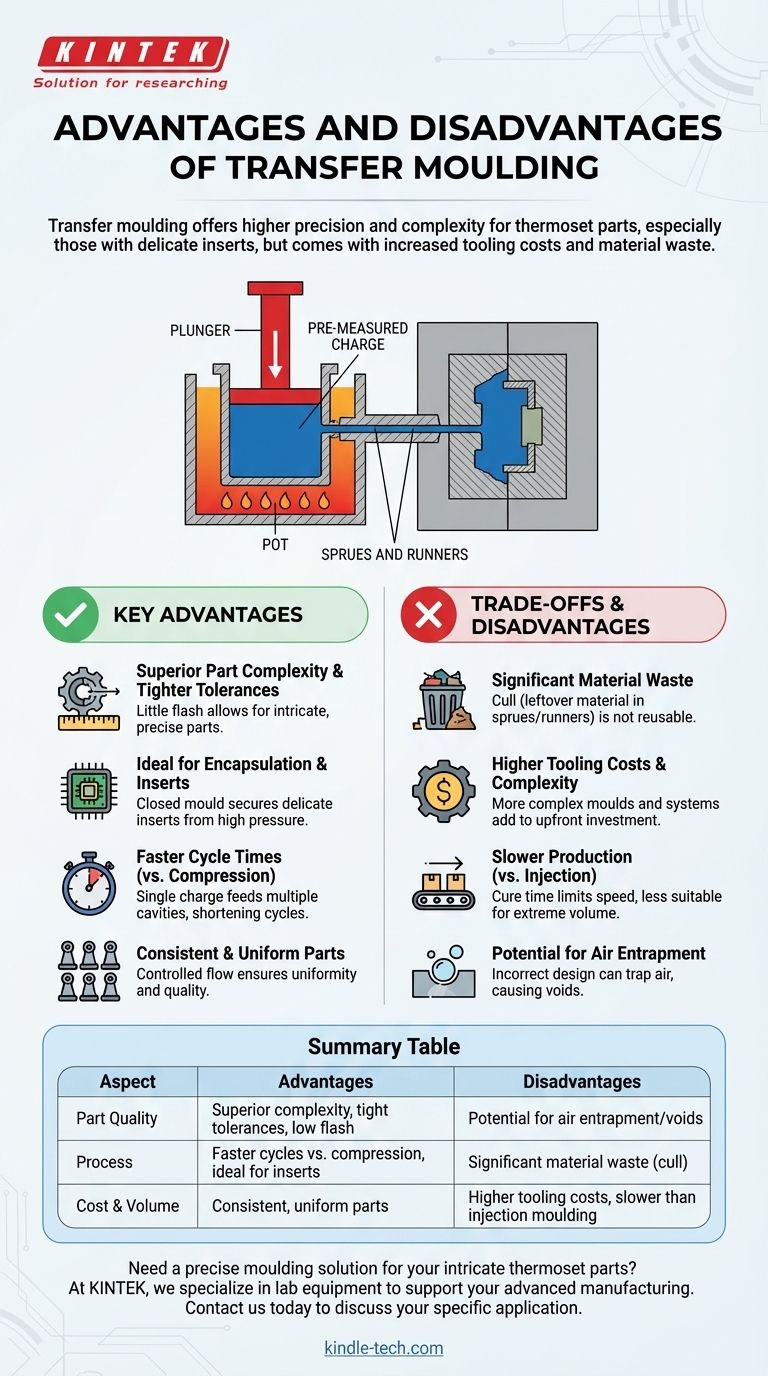

How Transfer Moulding Works: The Fundamentals

To understand its advantages and disadvantages, you must first understand the process. Unlike compression moulding where the material is placed directly into an open mould cavity, transfer moulding uses a different approach.

The Process in Brief

First, a pre-measured amount of thermoset material, called a charge, is placed into a chamber known as the "pot," which is part of the mould tool.

When the mould is closed, a plunger forces the material—now heated and softened—from the pot through channels called sprues and runners and into the closed mould cavities.

The material fills the cavities, cures under heat and pressure, and is then ejected as a finished part.

Key Advantages of Transfer Moulding

The unique nature of this closed-mould process gives rise to its primary benefits.

Superior Part Complexity and Tighter Tolerances

Because the material flows into a completely closed and clamped mould, there is very little flash (excess material squeezing out of the parting line). This allows for the creation of much more intricate and dimensionally precise parts than compression moulding.

Ideal for Encapsulation and Inserts

Transfer moulding is the premier choice for creating parts with pre-placed inserts, such as metal pins, threaded posts, or delicate electronic components. The mould is closed before the plastic is introduced, securing the inserts and preventing them from being displaced by the high, direct pressure of compression moulding.

Faster Cycle Times Than Compression Moulding

While a single charge is used, it can feed multiple cavities simultaneously through the runner system. Combined with the pre-heating of the charge in the pot, this often results in shorter cycle times per part compared to loading individual cavities in compression moulding.

Consistent and Uniform Parts

The closed-mould process ensures a more consistent flow of material into the cavities. This leads to parts with greater uniformity, fewer voids, and consistent density, improving overall quality and repeatability.

Understanding the Trade-offs and Disadvantages

No process is perfect. The complexity that provides transfer moulding's benefits also introduces its primary drawbacks.

Significant Material Waste

The material left in the pot, sprues, and runners—collectively known as the cull—is a fundamental part of the process. With thermoset plastics, which cannot be re-melted and reused, this cull represents pure material waste and a direct increase in the cost per part.

Higher Tooling Costs and Complexity

Transfer moulds are more complex and expensive to design and manufacture than compression moulds. The need for a separate pot, a plunger mechanism, and a precisely machined runner system adds to the upfront investment.

Slower Production Than Injection Moulding

While faster than compression moulding, the process is generally slower than thermoplastic injection moulding. The time required for the thermoset material to cure within the mould limits the overall production rate, making it less suitable for extremely high-volume runs.

Potential for Air Entrapment

If the mould and process are not designed correctly, air can become trapped within the cavities as the material flows in. This can create voids or surface imperfections in the final part, requiring careful tool design and process control to mitigate.

Making the Right Choice for Your Project

Selecting the correct moulding process requires balancing the complexity of your part, your production volume, and your cost constraints.

- If your primary focus is producing intricate thermoset parts with sharp corners and tight tolerances: Transfer moulding is an excellent choice due to its low-flash, closed-mould nature.

- If your primary focus is securely encapsulating electronic components or overmoulding delicate metal inserts: Transfer moulding's gentle, indirect filling process is a distinct advantage over compression moulding.

- If your primary focus is producing simple shapes at the lowest possible tool cost for low-volume runs: Compression moulding is likely the more economical option.

- If your primary focus is mass-producing millions of thermoplastic parts at the lowest possible unit cost: Thermoplastic injection moulding remains the industry standard for speed and efficiency.

Ultimately, choosing transfer moulding is a deliberate engineering decision to achieve a level of precision and design freedom that other processes cannot easily provide.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Part Quality | Superior complexity, tight tolerances, low flash | Potential for air entrapment/voids |

| Process | Faster cycles vs. compression, ideal for inserts | Significant material waste (cull) |

| Cost & Volume | Consistent, uniform parts | Higher tooling costs, slower than injection moulding |

Need a precise moulding solution for your intricate thermoset parts?

Transfer moulding is a strategic choice for achieving superior dimensional stability and encapsulating delicate inserts. At KINTEK, we specialize in providing the right lab equipment and consumables to support your advanced manufacturing and R&D processes.

Let our experts help you determine if transfer moulding is the optimal process for your project's requirements. Contact us today to discuss your specific application and how we can support your laboratory's success.

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Infrared Heating Quantitative Flat Plate Press Mold

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the classification of presses? A Guide to Mechanical, Hydraulic, and Servo Presses

- Why is a laboratory hydraulic press required for SHS reaction? Master Powder Compaction for Optimal Synthesis

- What are the three applications of a hydraulic press? From Metal Forming to Lab Precision

- What is KBr in chemistry? Discover Its Role in IR Spectroscopy and Beyond

- Why are high-precision laboratory hydraulic presses used for testing PHBV? Ensure Flawless Sample Preparation

- What are the two types of presses based on power source? Mechanical vs. Hydraulic Presses Explained

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What materials are used in a hydraulic press? High-Strength Steel for Maximum Force and Durability