At its core, hot pressing is a manufacturing process that uses simultaneous high temperature and pressure to densify materials and create parts with superior properties. By applying heat to soften the material and pressure to collapse internal voids, it produces components that are significantly stronger and less porous than those made by other methods.

The primary advantage of hot pressing is its ability to produce parts with minimal porosity and enhanced mechanical strength. However, the specific benefits depend critically on the method used: uniaxial hot pressing for cost-effective, simple shapes, and hot isostatic pressing (HIP) for achieving near-perfect density in complex, high-performance components.

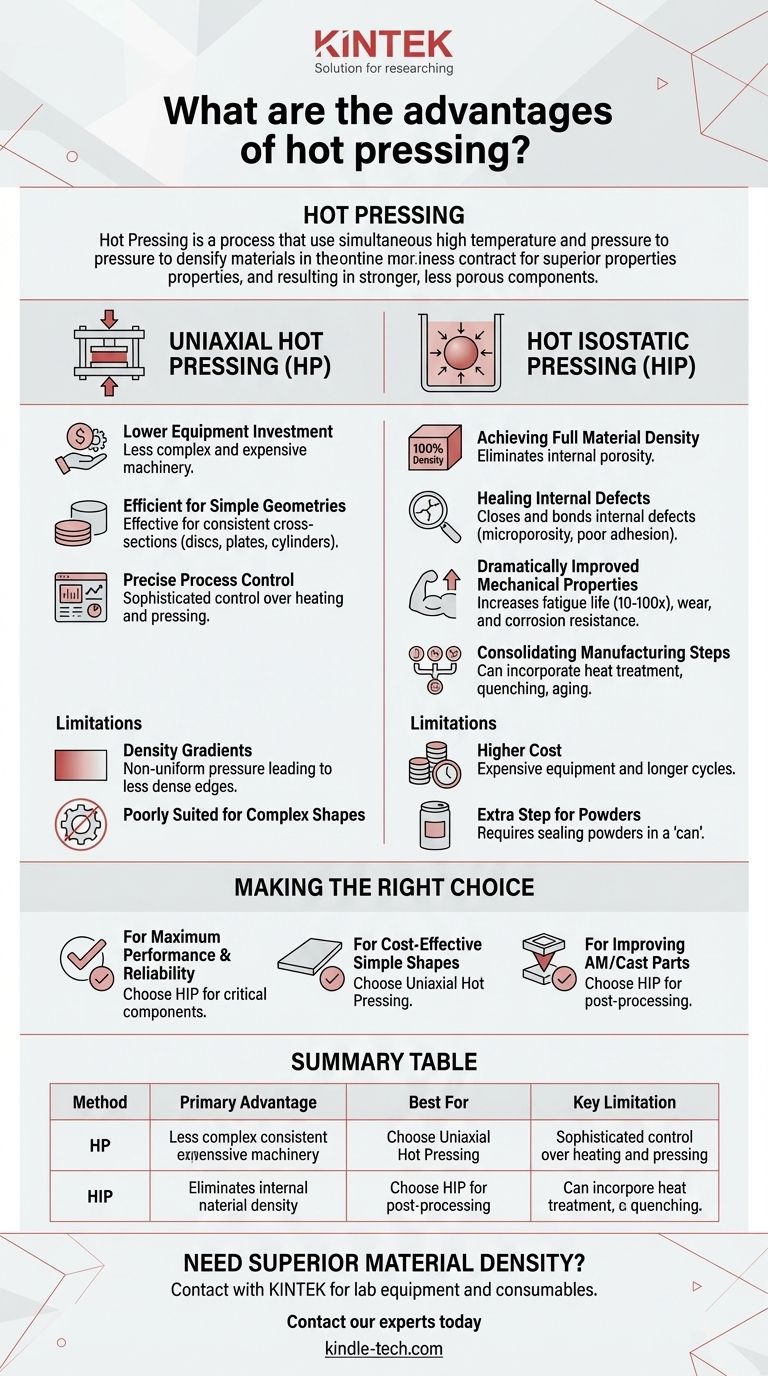

A Critical Distinction: Uniaxial vs. Isostatic Pressing

To understand the advantages, we must first distinguish between the two main forms of hot pressing. This choice dictates the cost, part geometry, and ultimate performance you can achieve.

Uniaxial Hot Pressing (HP)

This is the more conventional method. Powder is placed in a die, and pressure is applied from one direction (uniaxially), typically from the top and bottom, while the material is heated.

Hot Isostatic Pressing (HIP)

In this process, a part is heated in a high-pressure vessel. An inert gas, like argon, applies uniform, equal pressure from all directions (isostatically). This is often used on pre-formed parts, castings, or metal powders sealed campanha_can.

Key Advantages of Uniaxial Hot Pressing

Uniaxial hot pressing is a powerful choice when cost and production of simpler geometries are the main drivers.

Lower Equipment Investment

The machinery for uniaxial pressing is generally less complex and expensive than HIP systems, making it a more accessible technology.

Efficient for Simple Geometries

This method is highly effective for producing parts with a consistent cross-section, such as large-diameter discs, plates, and cylindrical targets.

Precise Process Control

Modern hot press machines offer sophisticated control over the heating cycle and pressing force. Features like pulse heating and real-time temperature curve displays allow for fine-tuned control over the densification process.

Key Advantages of Hot Isostatic Pressing (HIP)

HIP is the go-to process for a growing number of high-performance applications, from aerospace to medical implants, where material failure is not an option.

Achieving Full Material Density

HIP excels at eliminating virtually all internal porosity. By applying pressure uniformly, it can consolidate powders or heal voids in solid parts to achieve a density that is close to 100% of the theoretical maximum.

Healing Internal Defects

This process is uniquely capable of closing and bonding internal defects in castings and additively manufactured (3D printed) parts. It fixes issues like microporosity and poor layer adhesion, creating a uniform and robust internal microstructure.

Dramatically Improved Mechanical Properties

The elimination of internal defects 광고 a profound impact on performance. HIP can increase the fatigue life of a component by a factor of 10 to 100 and significantly improves wear resistance, ductility, and corrosion resistance.

Consolidating Manufacturing Steps

For certain alloys, the HIP cycle can be designed to incorporate heat treatment, quenching, and aging processes. This consolidation can significantly reduce overall production time and cost.

Understanding the Trade-offs

Choosing the right process requires acknowledging the limitations of each method.

Uniaxial Hot Pressing Limitations

Pressure is not uniform throughout the part. Friction with the die walls can lead to density gradients, mulheres the part may be less dense at the edges than in the center. This method is also poorly suited for complex, non-symmetrical shapes.

Hot Isostatic Pressing (HIP) Limitations

The primary trade-off is cost. HIP equipment is expensive to purchase and operate. Cycle times are also typically longer than uniaxial pressing. Furthermore, when starting with powders, they must be sealed in a metallic "can," which adds an extra step and cost to the process.

Making the Right Choice for Your Application

Your final decision should be guided by your component's performance requirements and economic constraints.

- If your primary focus is maximum performance and reliability for critical components: Hot Isostatic Pressing (HIP) is the definitive choice for eliminating internal defects and achieving theoretical density.

- If your primary focus is producing relatively simple, large-diameter shapes in a cost-effective manner: Uniaxial Hot Pressing offers a balanced solution with good densification and lower investment.

- If your primary focus is improving the quality of additively manufactured or cast parts: HIP is an essential post-processing step to heal porosity, relieve internal stresses, and unlock the material's full potential.

By understanding the distinct advantages of each method, you can select the right process to achieve your material performance and manufacturing goals.

Summary Table:

| Hot Pressing Method | Primary Advantage | Best For | Key Limitation |

|---|---|---|---|

| Uniaxial Hot Pressing (HP) | Lower equipment cost, efficient for simple shapes | Cost-effective production of discs, plates, cylinders | Density gradients, limited to simple geometries |

| Hot Isostatic Pressing (HIP) | Near-perfect density, heals internal defects | Critical components in aerospace, medical, AM/cast parts | Higher equipment and operational cost |

Need to achieve superior material density and performance for your lab components?

Whether you're developing high-performance targets, improving the reliability of additively manufactured parts, or consolidating powders, the choice between uniaxial hot pressing and hot isostatic pressing (HIP) is critical. KINTEK specializes in providing the right lab equipment and consumables to meet your specific manufacturing and R&D challenges.

Contact our experts today to discuss how our solutions can help you optimize your hot pressing process, enhance part performance, and achieve your material science goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- How does a Vacuum Hot Press Sintering Furnace (VHPS) produce high-density high-entropy alloys? Expert Insights

- What advantages does a hot press offer over cold pressing? Enhance Sulfide Solid-State Electrolyte Performance

- What is the spark plasma sintering method? Achieve Rapid, High-Density Material Consolidation

- How does vacuum hot-pressing sintering equipment solve W-Si composition segregation? Achieve Material Homogeneity

- Is spark a plasma sintering? Discover the Truth About SPS and Its Advantages

- How does Hot Isostatic Pressing (HIP) improve the properties of metal castings? Enhance Density and Fatigue Life

- Why is hot pressing preferred for UHMWPE radiation shielding? Overcome High Viscosity for Superior Density

- What are the technical advantages of using vacuum hot pressing for Mg2Si? Achieve Dense Nanocrystalline Structures