The primary advantages of induction casting are superior speed, precise control, and enhanced metal purity. Unlike conventional methods that heat metal from the outside with a flame or heating element, induction uses an electromagnetic field to generate heat directly inside the material. This fundamental difference leads to faster, cleaner, and more consistent results, making it the preferred method for high-performance applications.

The crucial takeaway is that induction casting is not just another way to melt metal; it is a fundamentally more controlled process. Its real advantage lies in translating that control into higher-quality, more homogeneous, and purer final castings with unparalleled repeatability.

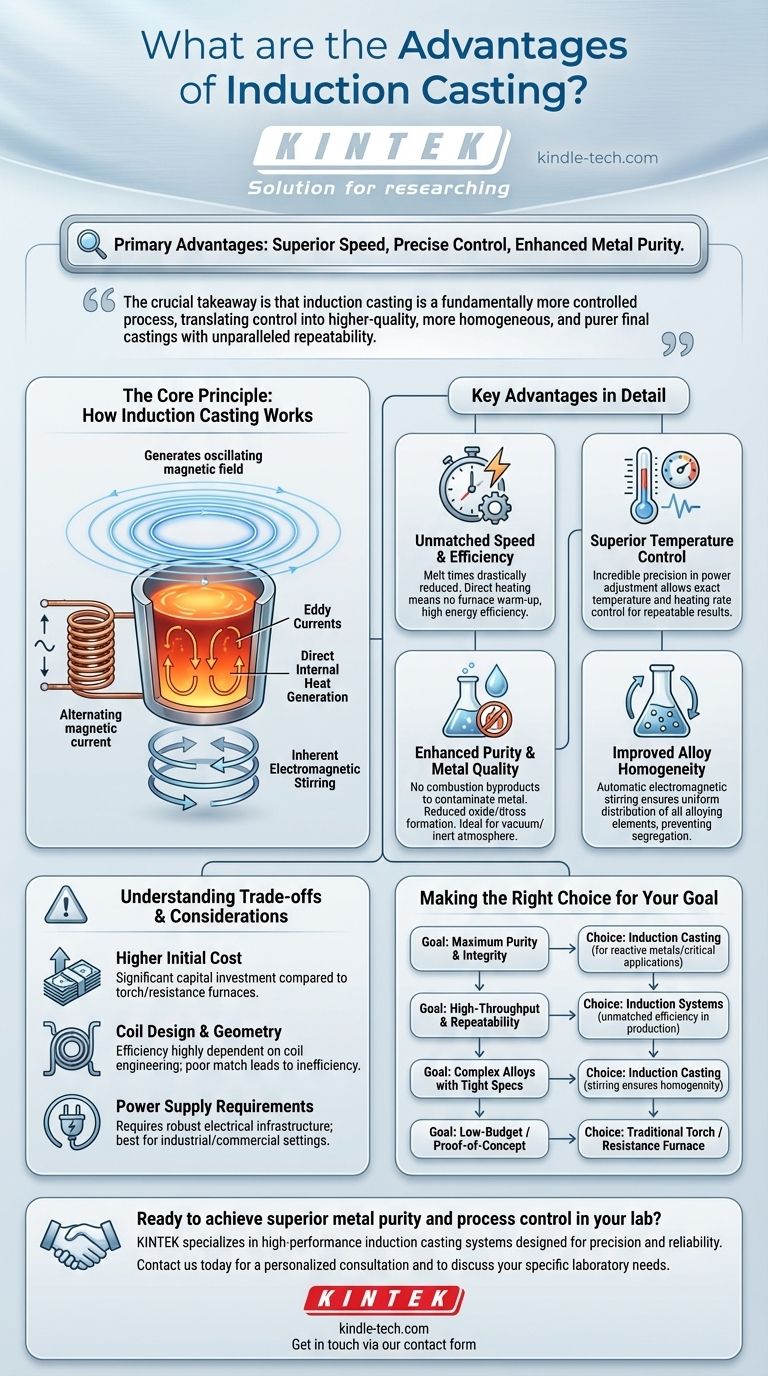

The Core Principle: How Induction Casting Works

To understand the benefits, you must first understand the mechanism. Induction casting is a non-contact process that relies on fundamental principles of electromagnetism.

Non-Contact Heating

An alternating electrical current is passed through a copper coil, creating a powerful, oscillating magnetic field. When a conductive material like metal is placed within this field (typically in a non-conductive crucible), the field induces electrical currents, known as eddy currents, within the metal itself.

Direct Internal Heat Generation

The resistance of the metal to the flow of these eddy currents generates rapid and intense heat. The metal is effectively its own heating element, warming from the inside out. This is far more efficient than trying to transfer heat from an external source through the surface of the material.

Inherent Electromagnetic Stirring

The same magnetic forces that generate heat also create a stirring action within the molten metal bath. This movement naturally mixes the melt, ensuring all elements, especially in alloys, are distributed evenly throughout the liquid.

Key Advantages in Detail

The unique mechanism of induction heating translates directly into significant operational and metallurgical advantages over torch or resistance furnace methods.

Unmatched Speed and Efficiency

Because heat is generated instantly and directly within the charge, melt times are drastically reduced. There is no need to wait for a furnace to warm up or for heat to slowly penetrate the metal. This direct heating process also means less energy is wasted heating the surrounding air, making induction highly energy-efficient.

Superior Temperature Control

The power supplied to the induction coil can be adjusted with incredible precision. This allows for exact control over the melting temperature and heating rate. This prevents the overheating of alloys, which can cause valuable elements to burn off or introduce gas porosity, leading to highly repeatable and predictable results from one cycle to the next.

Enhanced Purity and Metal Quality

Induction is an exceptionally clean process. Since there is no combustion, there are no byproducts from a flame to contaminate the metal. This significantly reduces the formation of oxides and dross. The process can also be easily performed in a vacuum or inert atmosphere, further protecting reactive metals from contamination.

Improved Alloy Homogeneity

The automatic electromagnetic stirring is a critical advantage. It ensures that all alloying elements are uniformly distributed throughout the melt, preventing segregation. This leads to a final cast part with consistent chemical composition and predictable mechanical properties throughout its structure.

Understanding the Trade-offs and Considerations

While powerful, induction casting is not the universal solution for every scenario. Acknowledging its limitations is key to making an informed decision.

Higher Initial Equipment Cost

Induction casting systems, including the power supply and custom coils, represent a significant capital investment. This cost is substantially higher than that of a simple gas torch or a basic resistance furnace, which may be prohibitive for smaller operations or hobbyists.

Coil Design and Geometry

Efficiency is highly dependent on the design of the induction coil and its proximity to the metal charge. The coil must be carefully engineered for the specific crucible size and shape. A poorly matched coil will lead to inefficient heating and longer melt times.

Power Supply Requirements

These systems require a robust and stable electrical infrastructure to operate. The high power draw means they are best suited for industrial or well-equipped commercial settings, and may not be feasible in all locations without electrical upgrades.

Making the Right Choice for Your Goal

Selecting a casting method depends entirely on your project's priorities, balancing quality requirements against operational costs.

- If your primary focus is maximum material purity and integrity: Induction is the definitive choice for casting reactive metals or alloys where contamination is a critical failure point.

- If your primary focus is high-throughput and repeatability: The rapid, precisely controlled melting cycles of induction systems offer unmatched efficiency and consistency in a production environment.

- If your primary focus is casting complex alloys with tight specifications: The inherent stirring action ensures the chemical homogeneity required for high-performance metallurgical applications.

- If your primary focus is a low-budget or proof-of-concept setup: Traditional torch melting or a resistance furnace offers a much lower barrier to entry for less demanding applications.

Ultimately, adopting induction casting is an investment in achieving superior process control and final product quality.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Efficiency | Drastically reduced melt times and high energy efficiency. |

| Precise Control | Exact temperature and heating rate control for repeatable results. |

| Enhanced Purity | No combustion byproducts; ideal for vacuum/inert atmosphere casting. |

| Alloy Homogeneity | Electromagnetic stirring ensures uniform composition. |

Ready to achieve superior metal purity and process control in your lab?

KINTEK specializes in high-performance lab equipment, including induction casting systems designed for precision and reliability. Our solutions help you produce high-quality, homogeneous castings with unmatched repeatability.

Contact us today to discuss how our induction casting technology can meet your specific laboratory needs. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the melting furnace process? Unlock Clean, Efficient Metal Melting with Induction Technology

- What is the hardest metal to melt? Tungsten Leads, But Advanced Materials Go Further

- What is the range of frequency for induction heating of machine use to melt metals without using fuel? Optimize Your Melting Process

- What are the advantages of channel induction furnace? Achieve Energy-Efficient Molten Metal Holding

- How does an induction furnace melt? Unlock the Power of Clean, Efficient Metal Melting

- What is the optimal frequency for induction heating? Matching Frequency to Your Material & Application

- What is the difference between high frequency and low frequency induction heating? Master the Skin Effect for Precision Results

- What are the characteristics of induction furnace? High-Efficiency, Clean Melting for Superior Metal Quality