At its core, isostatic compaction offers three primary advantages over traditional methods: achieving exceptionally uniform density, delivering consistent strength in all directions, and enabling the production of highly complex shapes. This unique combination allows for the creation of components with superior and more predictable mechanical properties.

The fundamental value of isostatic pressing is its ability to overcome the inherent limitations of other manufacturing processes. By applying pressure equally from all sides, it eliminates internal defects and unlocks design possibilities, resulting in parts with maximum material integrity.

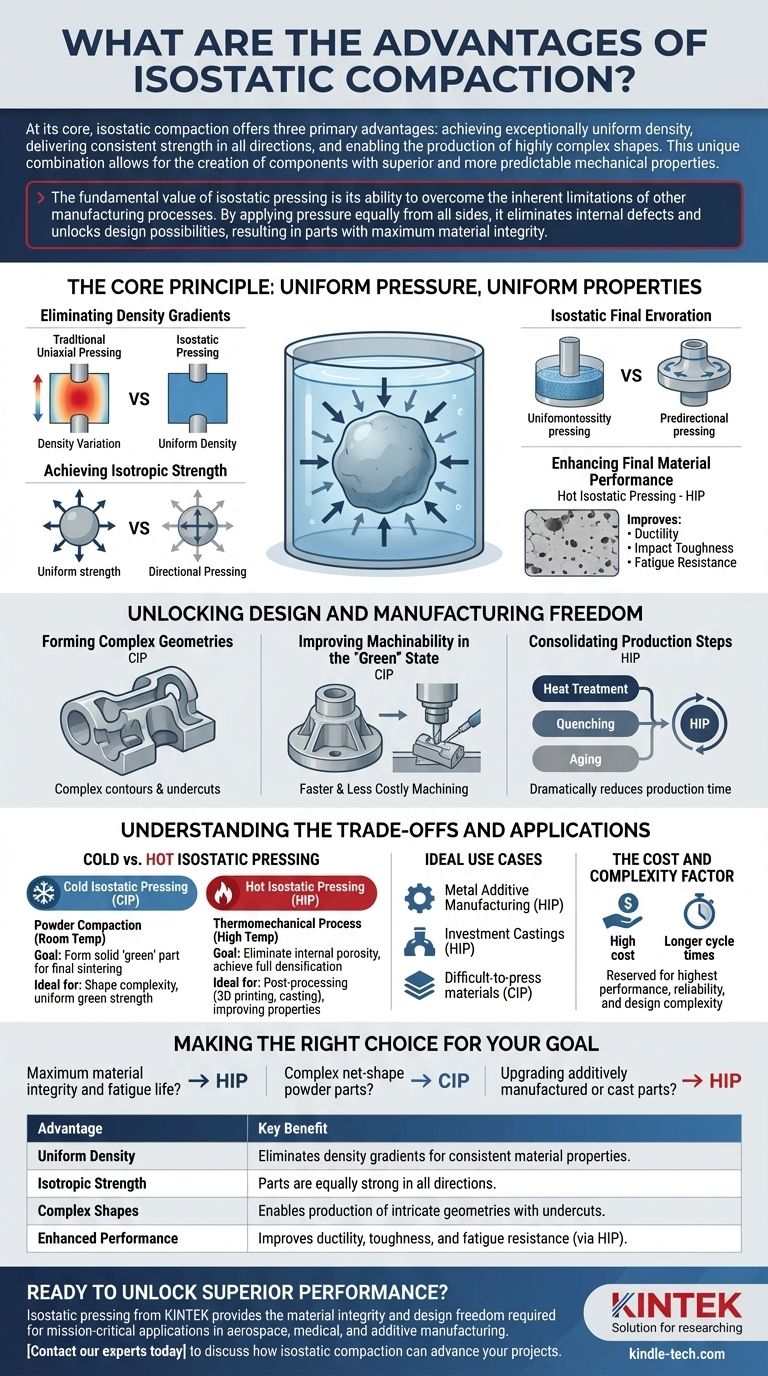

The Core Principle: Uniform Pressure, Uniform Properties

Isostatic pressing works by submerging a component—either as a powder in a flexible mold or a pre-formed part—in a fluid and pressurizing that fluid. This ensures pressure is applied equally and simultaneously to every surface of the component.

Eliminating Density Gradients

In traditional uniaxial pressing, where pressure is applied from only one or two directions, friction between the powder and the die walls creates density variations. The resulting part is denser near the punches and less dense in the middle. Isostatic pressing completely eliminates these gradients, producing a uniformly dense component.

Achieving Isotropic Strength

This uniform density directly translates to isotropic mechanical properties, meaning the material is equally strong in all directions. Parts are free from the weak axes or internal stress points that can form during directional pressing or casting, making them far more reliable under complex loading conditions.

Enhancing Final Material Performance

When applied at high temperatures (Hot Isostatic Pressing, or HIP), the process closes internal porosity and creates a uniform microstructure. This significantly improves critical properties like ductility, impact toughness, and fatigue resistance, bringing the performance of cast or 3D-printed parts up to the level of wrought materials.

Unlocking Design and Manufacturing Freedom

The use of uniform pressure and flexible tooling opens up possibilities that are simply not achievable with rigid dies.

Forming Complex Geometries

Cold Isostatic Pressing (CIP) uses flexible, elastomeric molds. This allows for the engineering of parts with complex contours, undercuts, and internal cavities that would be impossible to eject from a rigid die set used in uniaxial pressing.

Improving Machinability in the "Green" State

CIP produces a pre-sintered part (a "green" compact) with very high and uniform strength. This allows for intricate machining to be performed on the part before the final hardening and sintering process, which is often faster and less costly than machining the fully dense, hardened material.

Consolidating Production Steps

Hot Isostatic Pressing (HIP) can be engineered to combine multiple thermal processes into one. A single HIP cycle can simultaneously include heat treatment, quenching, and aging, consolidating manufacturing steps and dramatically reducing overall production time and part handling.

Understanding the Trade-offs and Applications

While powerful, isostatic pressing is a specific tool for specific challenges. The choice between Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) depends entirely on the goal.

Cold vs. Hot Isostatic Pressing

Cold Isostatic Pressing (CIP) is a powder compaction method used at or near room temperature. Its purpose is to form a solid "green" part from a powder before final sintering. It is chosen for shape complexity and uniform green strength.

Hot Isostatic Pressing (HIP) is a thermomechanical process used on an already-formed part (e.g., from casting, additive manufacturing, or CIP). Its purpose is to eliminate internal porosity and defects, achieving full densification and improving material properties.

Ideal Use Cases

HIP is a game-changing post-processing step for metal additive manufacturing (3D printing), where it heals porosity and remedies poor layer adhesion. It is also used to eliminate internal voids in investment castings for critical aerospace or medical applications. CIP excels in producing parts from difficult-to-press materials or soft electrolytes.

The Cost and Complexity Factor

Isostatic pressing systems represent a significant capital investment, and cycle times can be longer than conventional pressing. It is therefore a process reserved for applications where the highest possible performance, reliability, and design complexity justify the cost.

Making the Right Choice for Your Goal

Selecting the right compaction strategy requires a clear understanding of your component's end-use requirements.

- If your primary focus is maximum material integrity and fatigue life: Use HIP as a final densification step to eliminate internal defects in mission-critical components.

- If your primary focus is creating complex net-shape powder parts: Use CIP to achieve intricate geometries and high green strength that cannot be accomplished with uniaxial pressing.

- If your primary focus is upgrading additively manufactured or cast parts: Apply HIP as a post-processing step to achieve mechanical properties comparable to forged materials.

Ultimately, isostatic pressing empowers you to engineer materials and components that achieve an unparalleled level of performance and reliability.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Uniform Density | Eliminates density gradients for consistent material properties. |

| Isotropic Strength | Parts are equally strong in all directions. |

| Complex Shapes | Enables production of intricate geometries with undercuts. |

| Enhanced Performance | Improves ductility, toughness, and fatigue resistance (via HIP). |

Ready to unlock superior performance for your components?

Isostatic pressing from KINTEK provides the material integrity and design freedom required for mission-critical applications in aerospace, medical, and additive manufacturing. Our expertise in lab equipment and consumables ensures you get the right solution for densifying metal powders, healing porosity in 3D-printed parts, or creating complex ceramic components.

Contact our experts today to discuss how isostatic compaction can advance your projects.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is hot isostatic pressing and cold isostatic pressing? Key Differences for Your Manufacturing Process

- What is isostatic pressing of polymers? Achieve Superior Uniform Density for High-Performance Parts

- How does an isostatic press compare to a uniaxial press for Li3PS4 & Na3PS4? Find the Optimal Densification Method

- What is the critical role of a Cold Isostatic Press (CIP)? Enhance LSTH Perovskite Solid Electrolyte Densification

- What is the process of cold isostatic pressing? Achieve Uniform Density in Complex Parts

- Why is a cold isostatic press (CIP) required after Li/Li3PS4-LiI/Li battery assembly? Optimize Your Solid-State Interface

- How do industrial HIP furnaces facilitate diffusion bonding? Achieve Perfect Joints for Dissimilar Metals

- How does Cold Isostatic Pressing (CIP) benefit SiC ceramic reactors? Achieve Flawless Material Integrity