The primary advantage of liquid phase sintering is its ability to significantly accelerate the densification process at lower temperatures compared to solid-state methods. By introducing a small amount of a liquid-forming additive, the process creates a high-speed pathway for material transport, allowing particles to rearrange and bond more efficiently, resulting in stronger, denser final parts.

At its core, liquid phase sintering overcomes the slow, high-energy limitations of solid-state diffusion. It strategically uses a temporary liquid as a lubricant and transport medium to achieve densification faster, cheaper, and more effectively, especially for challenging materials.

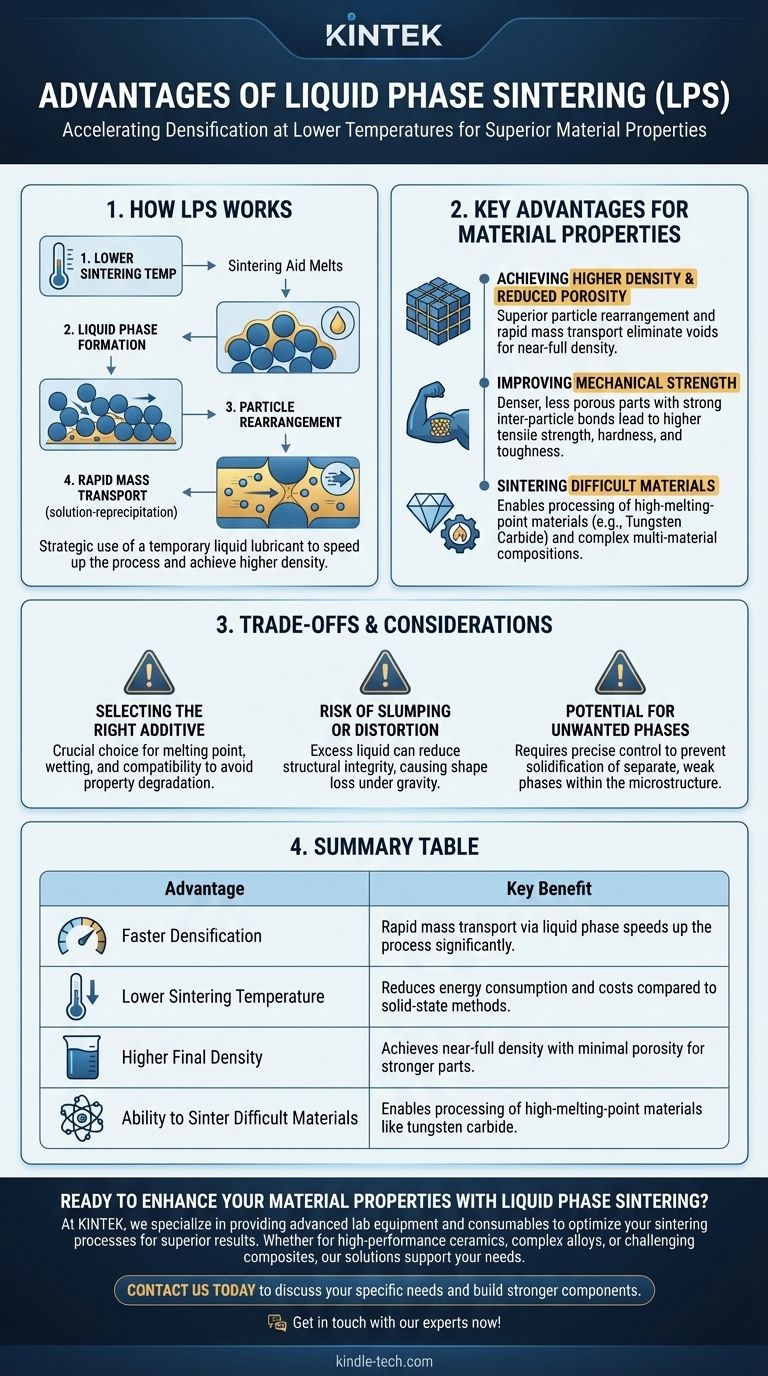

How Liquid Phase Sintering Fundamentally Works

To understand the benefits, it's essential to first understand the mechanism. Liquid phase sintering (LPS) introduces a secondary material (a sintering aid) that has a lower melting point than the primary powder. When heated, this aid melts, creating a liquid that coats the solid particles.

The Role of the Liquid Phase

The liquid acts as a powerful catalyst for the sintering process. It functions as a binder and a flux, wetting the surfaces of the primary powder particles and drawing them together through capillary action.

Lowering Sintering Temperatures

Because the sintering aid melts at a lower temperature than the main material, the entire process can be conducted at a reduced temperature. This saves significant energy and time, making the manufacturing process more efficient and cost-effective.

Enhancing Particle Rearrangement

The liquid phase effectively lubricates the solid particles. This allows them to slide past one another and settle into a much denser packing arrangement, which is a critical first step in eliminating porosity.

Accelerating Mass Transport

This is the most crucial function. Atoms from the solid particles can dissolve into the liquid, move rapidly through it, and then precipitate at the contact points (or "necks") between other particles. This solution-reprecipitation process is orders of magnitude faster than solid-state diffusion, dramatically speeding up neck growth and pore elimination.

The Key Advantages for Material Properties

The unique mechanism of LPS translates directly into superior outcomes for the final component, improving its physical and mechanical characteristics.

Achieving Higher Density and Reduced Porosity

By facilitating superior particle rearrangement and rapid mass transport, LPS is exceptionally effective at eliminating the voids between powder particles. The result is a component with near-full density and minimal porosity.

Improving Mechanical Strength

A denser, less porous part with strongly bonded inter-particle necks is inherently stronger and more durable. This process leads to significant improvements in properties like tensile strength, hardness, and toughness.

Sintering Difficult Materials

LPS makes it possible to process materials that are otherwise very difficult to sinter. This includes materials with extremely high melting points (like tungsten carbide) or complex multi-material compositions, as the liquid phase can facilitate bonding where solid-state methods would fail or be economically unfeasible.

Understanding the Trade-offs and Considerations

While powerful, liquid phase sintering requires precise control. It is not a universally superior solution and comes with its own set of engineering challenges that must be managed.

Selecting the Right Additive

The choice of the liquid-forming additive is critical. It must have the correct melting point, effectively wet the primary powder without reacting negatively, and either be fully absorbed into the final part or be removable without compromising integrity. An improper choice can degrade material properties.

Risk of Slumping or Distortion

Using too much of the liquid additive can cause the component to lose its shape during sintering. The excess liquid reduces the structural integrity of the powder compact, making it susceptible to slumping or distortion under gravity.

Potential for Unwanted Phases

The process must be carefully controlled to ensure the liquid phase is either fully integrated or removed. If not, it can solidify as a separate, unwanted phase within the material's microstructure, potentially creating weak points.

Making the Right Choice for Your Goal

Ultimately, the decision to use liquid phase sintering depends on the specific material system and the desired outcome for the final component.

- If your primary focus is achieving maximum density and production speed: LPS is almost always the superior choice due to its rapid mass transport mechanism.

- If your primary focus is processing high-melting-point or complex materials: LPS provides a practical and often necessary pathway to densify materials that are unfeasible via solid-state methods.

- If your primary focus is absolute chemical purity: Solid-state sintering may be preferred to avoid introducing a secondary sintering aid material.

- If your primary focus is cost-effective mass production of complex shapes: LPS offers significant advantages in energy savings, cycle times, and the ability to form near-net-shape parts.

By leveraging a controlled liquid phase, you can overcome many of the inherent limitations of solid powder metallurgy to create superior components.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Faster Densification | Rapid mass transport via liquid phase speeds up the process significantly. |

| Lower Sintering Temperature | Reduces energy consumption and costs compared to solid-state methods. |

| Higher Final Density | Achieves near-full density with minimal porosity for stronger parts. |

| Ability to Sinter Difficult Materials | Enables processing of high-melting-point materials like tungsten carbide. |

Ready to enhance your material properties with liquid phase sintering?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary to optimize your sintering processes. Whether you are working with high-performance ceramics, complex metal alloys, or challenging composites, our solutions help you achieve superior density, strength, and production efficiency.

Contact us today to discuss how we can support your laboratory's specific needs and help you build stronger, more reliable components.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- Why is a high vacuum environment necessary in sintering equipment for TiAl alloys? Ensure High-Purity Metal Bonding

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials