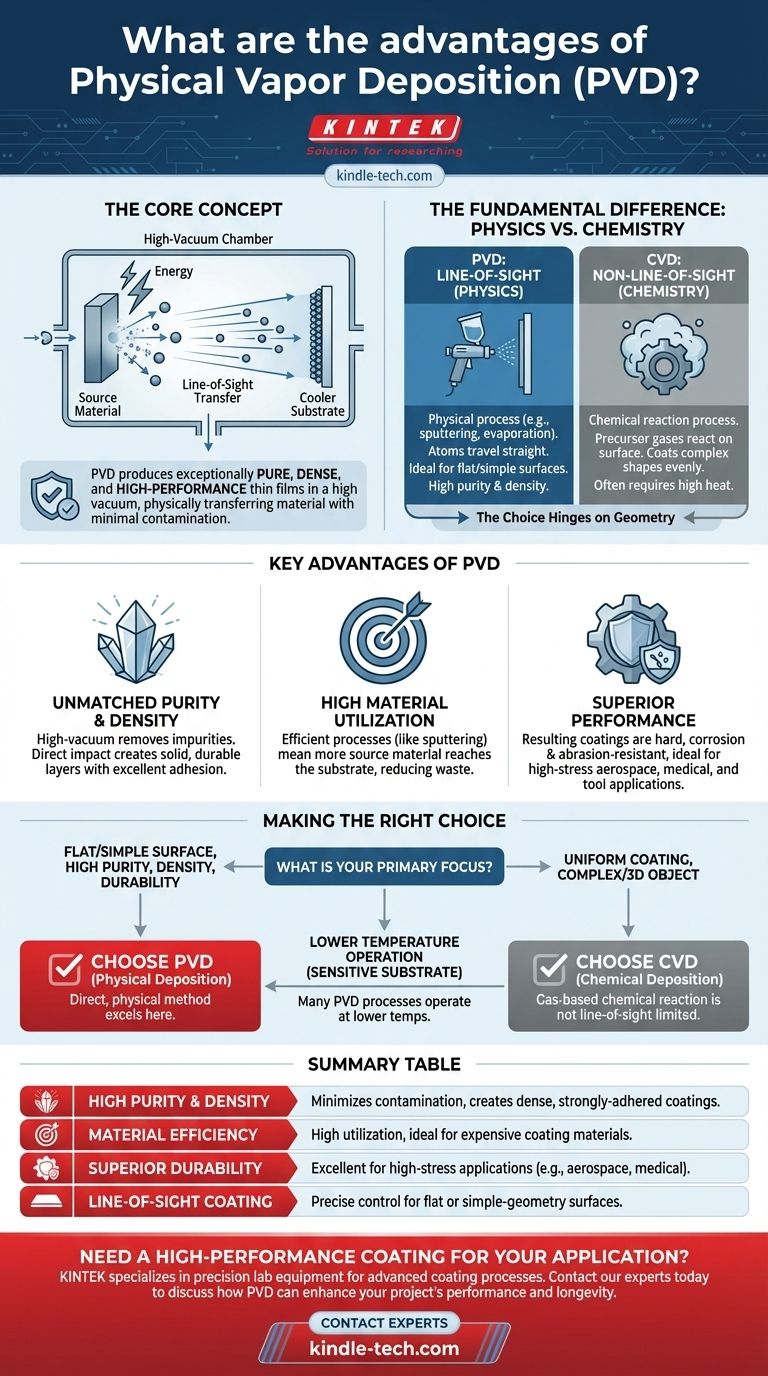

At its core, Physical Vapor Deposition (PVD) is valued for its ability to produce exceptionally pure, dense, and high-performance thin films and coatings. Because the process occurs in a high vacuum, it physically transfers coating material from a source to a target with minimal contamination, resulting in strong, durable layers with precise control over their characteristics.

The primary advantage of PVD is not just the quality of the coating, but the method of its creation. By using a physical process (like sputtering or evaporation) instead of a chemical one, PVD excels at creating extremely pure, high-density coatings on line-of-sight surfaces, which is a fundamental distinction from its common alternative, Chemical Vapor Deposition (CVD).

The Fundamental Difference: Physics vs. Chemistry

To understand the advantages of PVD, one must first grasp how it differs from CVD. The choice between them hinges on this core distinction.

How PVD Works: A Line-of-Sight Process

PVD uses mechanical or thermodynamic means to create a coating. In a high-vacuum chamber, a solid source material is bombarded with energy, causing atoms or molecules to escape its surface.

These particles travel in a straight line through the vacuum and deposit onto the cooler substrate, building a thin film layer by layer. This is a line-of-sight process, similar to spray painting.

How CVD Works: A Chemical Reaction Process

Chemical Vapor Deposition relies on chemistry, not physics. Precursor gases are introduced into a chamber where they react on the surface of the substrate.

This chemical reaction forms the desired solid material directly on the component. Because the gases can flow around an object, CVD is a non-line-of-sight process, capable of coating complex shapes evenly.

Key Advantages of Physical Vapor Deposition (PVD)

The physical, line-of-sight nature of PVD gives it a unique set of advantages for specific applications.

Unmatched Purity and Density

The high-vacuum environment is critical. It removes unwanted gas molecules that could otherwise be incorporated into the film as impurities.

This results in coatings of extremely high purity. The direct impact of energetic particles also tends to create very dense, solid layers with excellent adhesion and durability.

High Material Utilization

PVD processes, such as sputtering, can be very efficient. They offer a high sample utilization rate, meaning more of the source material ends up on the substrate and less is wasted. This is an important factor for expensive or specialized coating materials.

Superior Performance in Demanding Environments

The resulting dense and pure coatings are often very hard, corrosion-resistant, and abrasion-resistant. This makes PVD an ideal choice for high-stress applications like aerospace components, medical implants, and cutting tools.

Understanding the Trade-offs: PVD vs. CVD

No process is perfect. The advantages of PVD come with inherent limitations that make CVD a better choice in other scenarios.

The Line-of-Sight Limitation

PVD's greatest strength is also its main weakness. Because particles travel in a straight line, it is very difficult to uniformly coat the inside of tubes, complex geometries, or the backside of an object. CVD excels at this.

Process Complexity and Cost

Achieving and maintaining the high vacuum required for PVD is expensive and time-consuming. The equipment is complex, which can lead to higher initial investment and operational costs compared to some CVD systems.

Versatility in Chemistry

While PVD can deposit a vast range of metals, alloys, and ceramics, CVD's reliance on chemical reactions gives it a different kind of versatility. It is often better suited for creating specific compound films or for coating a wider array of substrate materials, including glass and ceramics.

Making the Right Choice for Your Goal

Selecting the right deposition method requires aligning the process capabilities with your primary objective.

- If your primary focus is coating a flat or simple surface with a highly pure, dense, and durable film: PVD is often the superior choice due to its direct, physical deposition method.

- If your primary focus is uniformly coating a complex, three-dimensional object: CVD is the better option because its gas-based chemical reaction is not limited by line-of-sight.

- If your primary focus is operating at lower temperatures to protect a sensitive substrate: Many PVD processes operate at lower temperatures than CVD, which often requires heat to drive its chemical reactions.

Ultimately, your application's geometry and required material properties will determine whether a physical or chemical deposition process is the right solution.

Summary Table:

| Advantage | Description |

|---|---|

| High Purity & Density | High-vacuum process minimizes contamination, creating dense, strongly-adhered coatings. |

| Material Efficiency | High material utilization rate, ideal for expensive coating materials. |

| Superior Durability | Excellent for high-stress applications (e.g., aerospace, medical implants, cutting tools). |

| Line-of-Sight Coating | Precise control for coating flat or simple-geometry surfaces effectively. |

Need a high-performance coating for your application?

KINTEK specializes in precision lab equipment and consumables for advanced coating processes. Whether you're developing medical implants, aerospace components, or cutting tools, our expertise can help you select the right PVD solution to achieve superior purity, density, and durability for your materials.

Contact our experts today to discuss how PVD can enhance your project's performance and longevity.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What precautions must be followed while working in a lab? Cultivate a Mindset of Proactive Awareness

- What are the problems with electric arc furnace? Balancing High Costs with Unmatched Flexibility

- What is the difference between RF sputtering and DC sputtering? Choose the Right Method for Your Material

- What is the uniformity of e beam evaporation? Achieve Precise, Uniform Thin Films

- Is sputtering better than evaporation step coverage? Yes, for Superior Coating on Complex Surfaces

- What are the uses of biochar from pyrolysis? Engineer Its Properties for Your Specific Goal

- What is a metal test called? A Guide to Heavy Metals Panels and Toxic Exposure Testing

- What is the role of a laboratory oven in ZnO-Au nanocomposites? Achieve Precision Drying and Material Stability