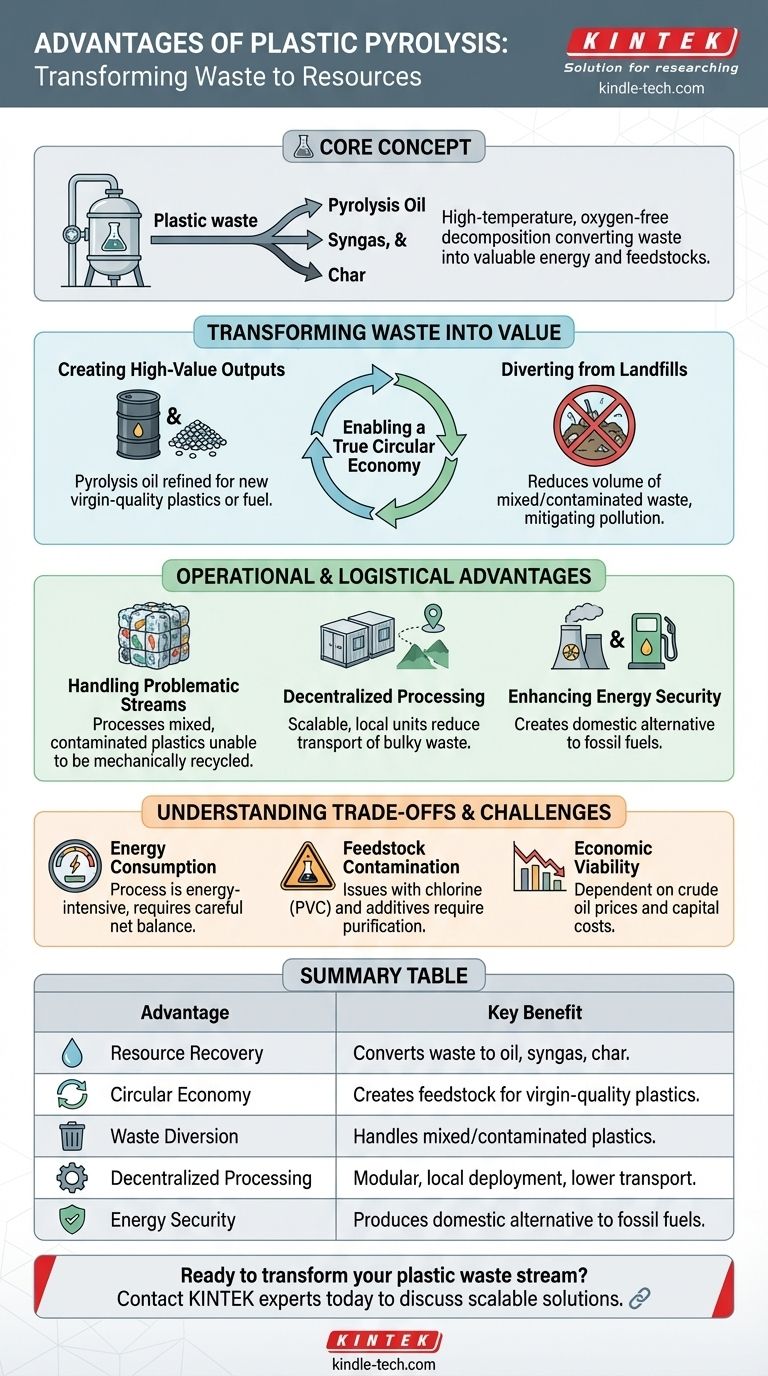

At its core, plastic pyrolysis is a technology that converts plastic waste into valuable resources through a process of high-temperature thermal decomposition in an oxygen-free environment. This method directly addresses the challenge of non-recyclable plastics by transforming them into pyrolysis oil, syngas, and char, effectively turning a global waste problem into a source of energy and chemical feedstocks.

Plastic pyrolysis offers a powerful advantage by chemically recycling mixed and contaminated plastic waste that traditional methods cannot handle. It breaks down polymers into their original building blocks, creating a pathway for a circular economy by producing liquid feedstock for new plastics and fuels.

Transforming Waste into a Valuable Resource

The primary advantage of plastic pyrolysis lies in its ability to create value from materials that would otherwise be permanently discarded. It functions as a form of advanced, or chemical, recycling.

Creating High-Value Outputs

The main product of plastic pyrolysis is pyrolysis oil (py-oil), a synthetic liquid hydrocarbon mixture. This oil can be refined and used as a feedstock to produce new, virgin-quality plastics, closing the material loop.

Alternatively, this oil can be used directly as an industrial fuel or further processed into transportation fuels like diesel, offering a direct alternative to fossil fuels. Other outputs, like syngas and char, can be used to power the pyrolysis process itself, improving its energy efficiency.

Diverting Plastic from Landfills and Incineration

A significant portion of plastic waste, particularly mixed or contaminated types, cannot be mechanically recycled. Pyrolysis provides a solution for this difficult waste stream.

By processing these plastics, the technology drastically reduces the volume of waste sent to landfills, mitigating land use and the potential for environmental pollution from plastic degradation.

Enabling a True Circular Economy

Unlike mechanical recycling, which often results in "downcycling" to lower-quality products, pyrolysis breaks polymers down to a molecular level. This allows for the creation of new plastics that are indistinguishable from those made from virgin fossil resources.

This process is a key enabler of a circular economy, reducing the systemic demand for new fossil fuel extraction to create plastics.

Operational and Logistical Advantages

Beyond its environmental benefits, pyrolysis presents several practical advantages in waste management logistics and energy production.

Handling Problematic Plastic Streams

Mechanical recycling requires clean, sorted, single-stream plastics. Pyrolysis plants are far more flexible, capable of processing mixed plastic bales and withstanding a higher degree of contamination from labels, food residue, and other materials.

This capability significantly expands the range of plastic waste that can be effectively recycled.

Decentralizing Waste Processing

Pyrolysis facilities can be built at various scales, including smaller, modular units. This allows for decentralized deployment in remote areas or directly at large waste-generating sites.

This model converts bulky, low-density plastic waste into a dense, energy-rich liquid that is far cheaper and easier to transport to central refineries or chemical plants.

Enhancing Energy Security

By converting a domestic waste stream into liquid fuel, pyrolysis contributes to local energy security. It creates a reliable, domestically-sourced alternative to conventional fossil fuels, reducing reliance on volatile global energy markets.

Understanding the Trade-offs and Challenges

While promising, pyrolysis is not a silver bullet. An objective assessment requires acknowledging its complexities and current limitations.

Energy Consumption and Emissions

Pyrolysis is an energy-intensive process that requires high temperatures. The net energy balance—the energy produced minus the energy consumed—must be carefully managed to ensure the process is a net positive.

Furthermore, the full lifecycle carbon footprint, including transportation and post-processing of the py-oil, must be rigorously assessed to validate its environmental benefits over other disposal methods.

Feedstock Contamination Issues

Certain contaminants in the plastic waste stream can pose significant challenges. For example, plastics containing chlorine (like PVC) can produce hydrochloric acid, which is highly corrosive and requires specialized, expensive equipment.

Other additives, flame retardants, and impurities can transfer into the pyrolysis oil, necessitating costly and complex purification steps before it can be used as a high-quality chemical feedstock.

Economic Viability

The economic feasibility of plastic pyrolysis is highly dependent on external market forces, particularly the price of conventional crude oil. When crude oil prices are low, py-oil can be less competitive as a feedstock or fuel.

High capital investment for the plant and ongoing operational costs for energy and purification mean that economic viability often relies on subsidies, gate fees for waste processing, or stable, long-term offtake agreements.

How to Evaluate Pyrolysis for Your Goal

To determine if pyrolysis is the right solution, you must align its capabilities with your specific objectives.

- If your primary focus is waste management and landfill diversion: Pyrolysis is an excellent tool for handling mixed and contaminated plastic streams that are otherwise destined for a landfill.

- If your primary focus is creating circular materials: Pyrolysis is one of the few technologies capable of breaking down old plastics into high-quality feedstock for producing new, virgin-equivalent plastics.

- If your primary focus is sustainable investment: Scrutinize the technology's full lifecycle analysis, energy balance, and economic model to ensure it delivers a genuine environmental and financial return.

Plastic pyrolysis represents a critical and technologically advanced tool in the fight against plastic waste, offering a path to circularity where traditional methods fall short.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Resource Recovery | Converts waste plastic into pyrolysis oil, syngas, and char. |

| Circular Economy | Breaks down polymers to create feedstock for new, virgin-quality plastics. |

| Waste Diversion | Handles mixed, contaminated plastics that mechanical recycling cannot. |

| Decentralized Processing | Modular plants can be deployed locally, reducing transport costs. |

| Energy Security | Produces a domestic alternative to fossil fuels. |

Ready to transform your plastic waste stream into a valuable resource?

KINTEK specializes in advanced laboratory equipment and pyrolysis solutions for waste management and material science. Our expertise can help you evaluate and implement pyrolysis technology to achieve your sustainability and circular economy goals.

Contact our experts today to discuss how we can support your project—from initial analysis to scalable solutions.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products