In essence, vacuum firing is a highly controlled thermal process that offers significant advantages by eliminating atmospheric interference. Its primary benefits are the prevention of oxidation and contamination, the active removal of trapped gases and impurities from the material, and the ability to achieve superior final properties and surface finishes.

The core value of vacuum firing is not merely heating a material, but fundamentally changing its environment. By removing reactive gases, you prevent undesirable surface reactions and actively purify the material from within, achieving a level of quality often impossible in a standard atmosphere.

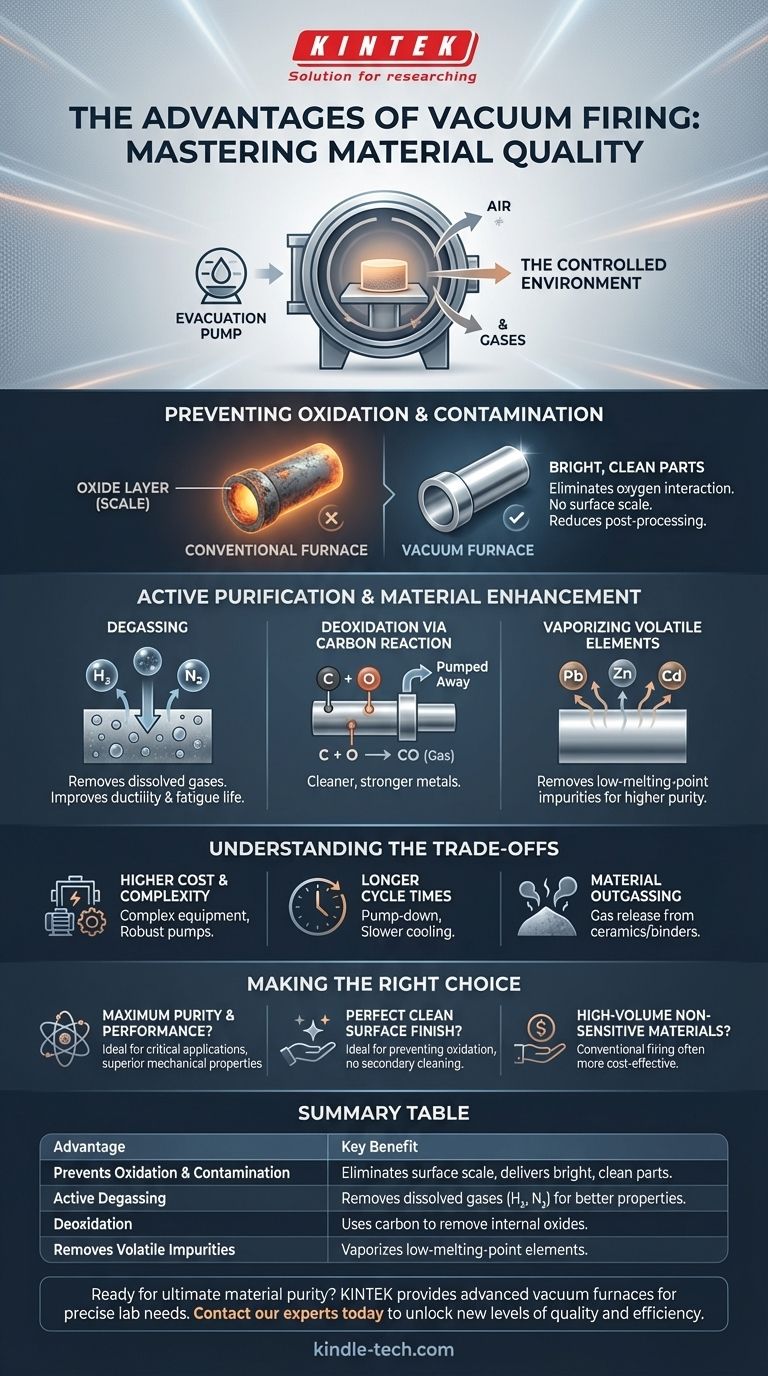

The Fundamental Advantage: Controlling the Environment

The most significant benefit of vacuum firing stems from removing the air—and its reactive components—from the heating chamber. This creates an inert environment that prevents unwanted chemical reactions.

Preventing Oxidation and Contamination

In a conventional furnace, the oxygen in the air will react with a hot metal surface, forming an oxide layer, or scale. This discoloration must often be cleaned off in a secondary step.

Vacuum firing eliminates virtually all oxygen, preventing this oxidation from ever occurring. This results in bright, clean parts directly out of the furnace, reducing post-processing labor and costs.

Creating an Ultra-Clean Workspace

Beyond just oxygen, the atmosphere contains nitrogen, water vapor, and other trace elements that can contaminate a workpiece at high temperatures. A vacuum removes these potential pollutants, ensuring the material only interacts with the intended thermal energy.

Active Purification and Material Enhancement

A vacuum doesn't just create a passive shield; it actively pulls unwanted elements out of the material itself, a process that significantly improves the final product's integrity.

Degassing: Removing Trapped Impurities

Many materials contain dissolved gases like hydrogen and nitrogen trapped within their molecular structure. Under the combined influence of high heat and low pressure, these gases are drawn out of the material and removed by the vacuum pump.

Removing these gases improves the material's mechanical properties, such as ductility and fatigue life, by eliminating internal voids and sources of embrittlement.

Deoxidation via Carbon Reaction

For certain metals and alloys, a vacuum enables a powerful purification process. Carbon present in the alloy can react with metal oxides to form carbon monoxide (CO) gas.

In a vacuum, this CO gas is continuously pumped away. This action effectively pulls oxygen out of the material's chemistry, resulting in a much cleaner, deoxidized metal with superior performance.

Vaporizing Volatile Elements

The low-pressure environment also lowers the boiling point of many elements. This can be used strategically to remove undesirable, low-melting-point impurities like lead, zinc, or cadmium from an alloy, as they will vaporize and be pumped out of the system.

Understanding the Trade-offs

While powerful, vacuum firing is not the solution for every application. Understanding its limitations is key to making an informed decision.

Higher Cost and Complexity

Vacuum furnaces are significantly more complex than their atmospheric counterparts. The need for robust vacuum pumps, precise seals, and sophisticated control systems makes them more expensive to purchase, operate, and maintain.

Longer Cycle Times

Achieving a high vacuum is not instantaneous. The "pump-down" time before the heating cycle can begin, combined with often slower, more controlled cooling ramps, means overall process times are typically longer than in a conventional furnace.

Material Outgassing

Some materials, particularly certain ceramics or powder metal binders, can release large volumes of gas during heating. This outgassing can overwhelm the vacuum system or, in extreme cases, the material itself can vaporize and coat the inside of the furnace.

Making the Right Choice for Your Process

Your specific goal determines whether the benefits of vacuum firing justify its costs and complexity.

- If your primary focus is maximum material purity and performance: Vacuum firing is the definitive choice for removing dissolved gases and internal oxides to achieve superior mechanical properties.

- If your primary focus is a perfect, clean surface finish: Vacuum processing is ideal, as it prevents oxidation and delivers bright parts that require no secondary cleaning.

- If your primary focus is high-volume processing of non-sensitive materials: Conventional atmospheric firing is often the more practical and cost-effective solution.

Ultimately, choosing vacuum firing is an investment in absolute control over your material's final quality and integrity.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Oxidation & Contamination | Eliminates surface scale, delivers bright, clean parts without post-processing. |

| Active Degassing | Removes dissolved gases (H₂, N₂) to improve ductility and fatigue life. |

| Deoxidation | Uses carbon to remove internal oxides, resulting in cleaner, stronger metals. |

| Removes Volatile Impurities | Vaporizes low-melting-point elements like zinc or lead for higher purity. |

Ready to achieve ultimate material purity and performance in your lab?

Vacuum firing is the definitive solution for applications requiring maximum material integrity, from preventing oxidation to actively removing internal impurities. If your work demands superior surface finishes and enhanced mechanical properties, the controlled environment of a vacuum furnace is essential.

KINTEK specializes in advanced lab equipment, including vacuum furnaces, to meet the precise needs of laboratories focused on material science and high-purity processing.

Contact our experts today to discuss how a vacuum firing solution can be tailored to your specific process and help you unlock new levels of quality and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the working principle of heat treatment furnace? A Guide to Controlled Material Transformation

- Why is a double vacuum resistance furnace recommended for magnesium recovery? Ensuring Safety & Stability

- How does annealing affect hardness? The Science of Softening Metals for Better Workability

- What is the temperature of debinding? A Guide to Mastering the Thermal Profile for MIM/CIM

- What is the difference between plasma nitriding and nitriding? Unlock Superior Surface Hardening Control

- What is the primary function of a vacuum oven in FEP membrane prep? Ensure Defect-Free Fiber Production

- What is the primary function of a vacuum heating furnace? Optimize High-Purity Li2O Synthesis

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys