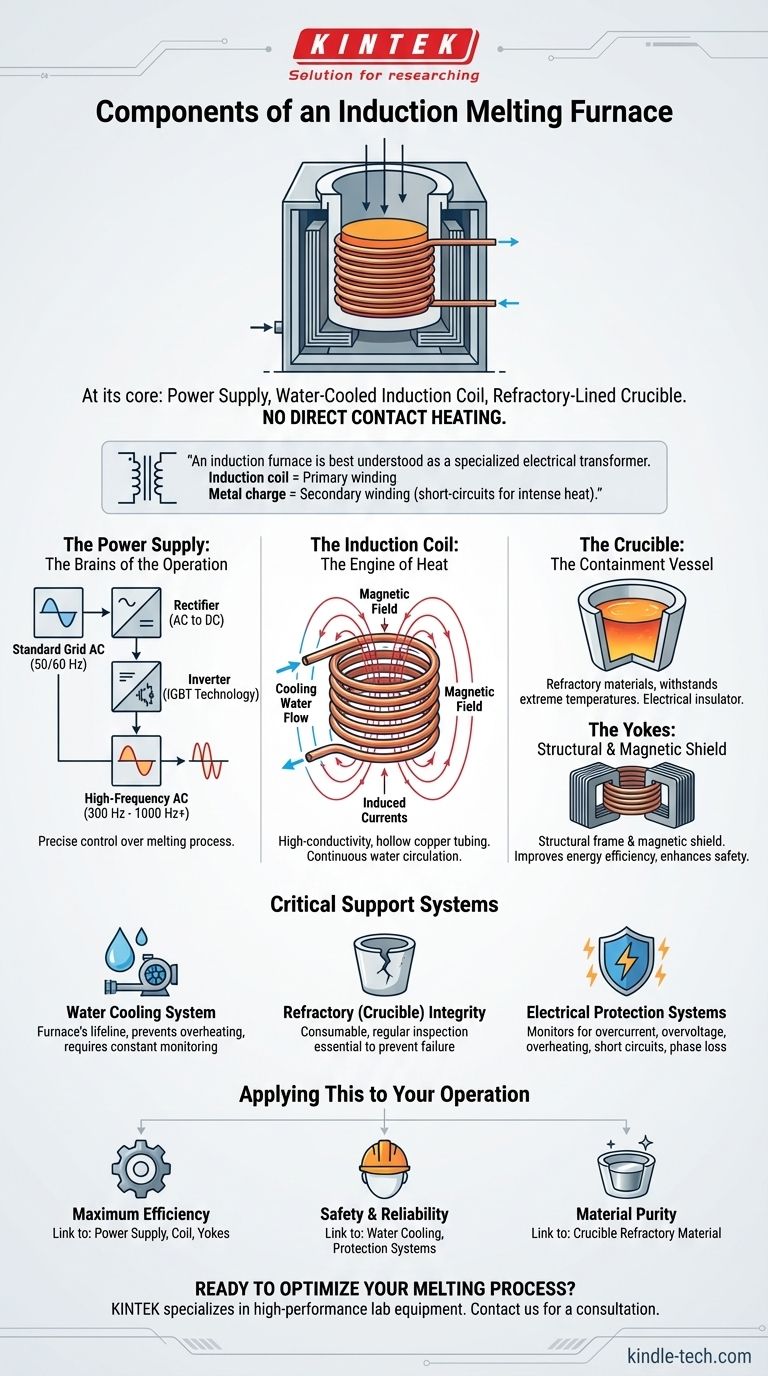

At its core, an induction melting furnace consists of three primary components: a power supply unit, a water-cooled induction coil, and a refractory-lined crucible. The power supply provides a high-frequency alternating current to the coil, which generates a powerful magnetic field. This field induces intense electrical currents within the metal placed inside the crucible, causing it to heat rapidly and melt without any direct contact from the heat source.

An induction furnace is best understood as a specialized electrical transformer. The furnace's induction coil acts as the primary winding, while the metal charge inside the crucible becomes the secondary winding, which effectively short-circuits and generates its own intense heat.

The Core Components and Their Functions

To truly understand how an induction furnace operates, we must examine the specific role of each major component. They work together as an integrated system to convert electrical energy into thermal energy with remarkable efficiency.

The Power Supply: The Brains of the Operation

The power supply is the control center of the entire system. Its primary job is to convert standard, low-frequency (50/60 Hz) three-phase alternating current (AC) from the grid into a high-frequency, single-phase current.

This conversion process typically involves first rectifying the AC into direct current (DC) and then using an inverter (often based on modern IGBT technology) to generate a new AC output at a much higher frequency, anywhere from 300 Hz to 1000 Hz or more.

The ability to adjust this frequency and power output gives operators precise control over the melting process, a key advantage of induction technology.

The Induction Coil: The Engine of Heat

The induction coil is the "engine" of the furnace. It is a precision-engineered coil, almost always made from high-conductivity copper tubing, through which the high-frequency current from the power supply flows.

As current passes through the coil, it generates a strong, rapidly reversing magnetic field in the open space within its center. To handle the immense electrical currents and resulting resistive heat, the copper tubing is hollow, allowing cooling water to be continuously circulated through it.

The Crucible: The Containment Vessel

The crucible is the vessel that holds the metal to be melted. It is placed within the induction coil but does not touch it.

This component is made from refractory materials—specialized ceramics that can withstand extreme temperatures and thermal shock. Critically, the crucible must be an electrical insulator to allow the magnetic field to pass through it unimpeded and act directly on the metallic charge inside.

The Yokes: The Structural and Magnetic Shield

Surrounding the induction coil are laminated steel packets known as yokes. These serve a dual purpose.

First, they provide a strong structural frame to support the coil and protect it from potential impact. Second, they act as a magnetic shield, confining the magnetic field and preventing it from straying, which improves energy efficiency and enhances operator safety.

Critical Support Systems and Operational Risks

The core components define the furnace, but several support systems are just as critical for safe and reliable operation. Ignoring them introduces significant risk.

The Water Cooling System

The water cooling circuit is the furnace's lifeline. The massive electrical currents flowing through the induction coil would cause it to overheat and fail within seconds without active cooling.

This system requires constant monitoring for flow rate, pressure, and temperature. Any interruption, such as from a pump failure or water shortage, will trigger an immediate shutdown via the furnace's protection systems.

Refractory (Crucible) Integrity

The crucible is a consumable item. It is subjected to extreme thermal cycling, chemical reactions with molten metal, and physical stress.

Gradual wear and erosion are inevitable. Regular inspection for cracks or thinning is essential, as a crucible failure would release molten metal, posing an extreme safety hazard and likely destroying the induction coil.

Electrical Protection Systems

A modern induction furnace is equipped with a suite of self-preservation functions. These systems monitor for dangerous conditions and protect the high-value power supply and coil assembly.

Common protections include monitoring for overcurrent, overvoltage, overheating, short circuits, and phase loss. These features are not optional extras; they are fundamental to the equipment's long-term reliability and safety.

Applying This to Your Operation

Understanding these components helps you make informed decisions based on your primary objective for using an induction furnace.

- If your primary focus is maximum efficiency: The design of your power supply (e.g., IGBT-based), coil, and magnetic yokes are the most critical factors.

- If your primary focus is safety and reliability: You must prioritize robust, well-monitored water cooling and a comprehensive suite of electrical protection systems.

- If your primary focus is material purity: Your choice of crucible refractory material is the most important decision, as it is the only component in direct contact with the melt.

By seeing the furnace as an interconnected system rather than just a collection of parts, you gain true control over your melting process.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Power Supply | Converts grid power to high-frequency AC | Precise control via IGBT technology |

| Induction Coil | Generates magnetic field to heat metal | Water-cooled copper tubing |

| Crucible | Holds the metal charge during melting | Refractory, electrically insulating material |

| Yokes | Structural support and magnetic shielding | Laminated steel packets for efficiency |

| Water Cooling System | Prevents coil overheating | Critical for safe, continuous operation |

| Protection Systems | Monitors for faults (overcurrent, overheating) | Essential for safety and reliability |

Ready to optimize your melting process with a reliable induction furnace?

KINTEK specializes in high-performance lab equipment, including induction melting systems designed for maximum efficiency, safety, and material purity. Our experts will help you select the right furnace components—from advanced IGBT power supplies to durable refractory crucibles—tailored to your specific laboratory needs.

Contact us today for a consultation and discover how KINTEK's solutions can enhance your lab's capabilities and reliability.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab