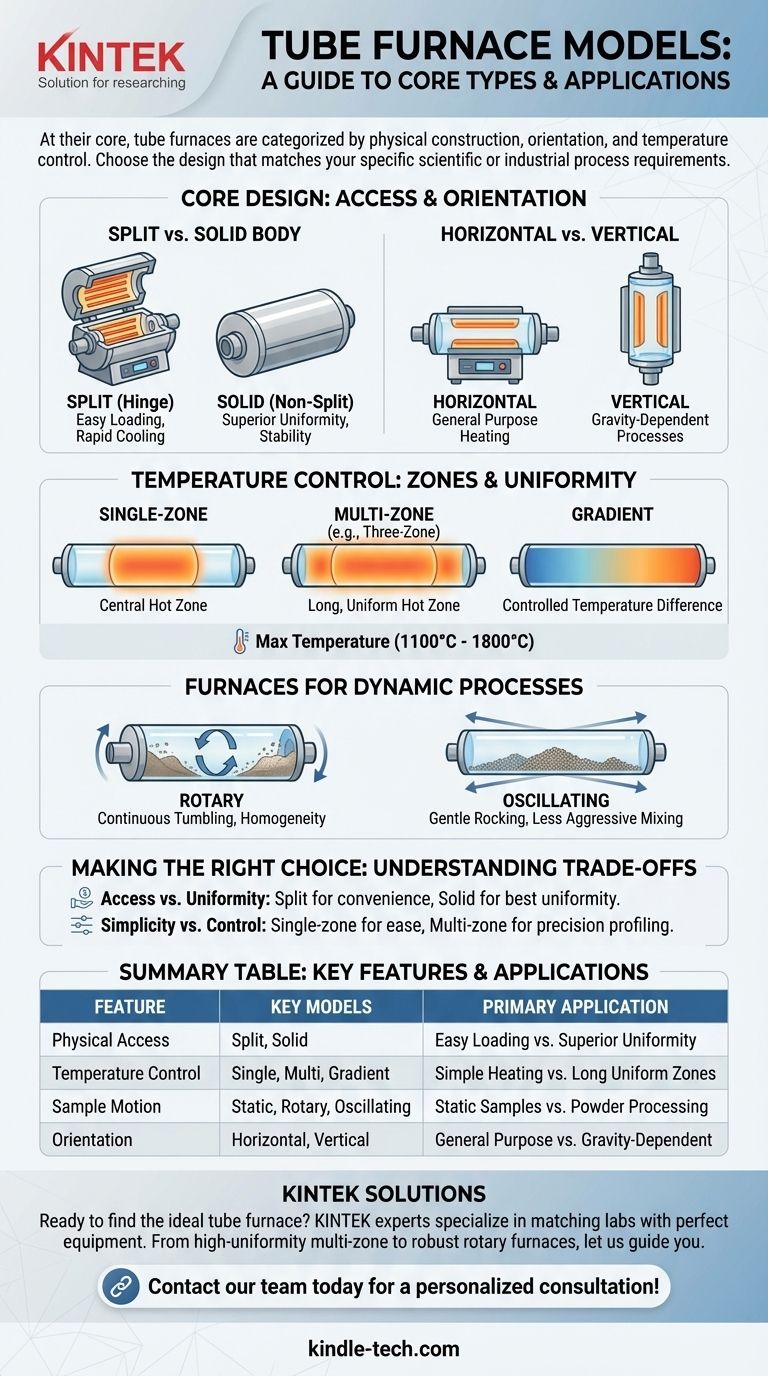

At their core, tube furnaces are categorized by their physical construction, orientation, and method of temperature control. The primary models available are single or multi-zone, horizontal or vertical, split or solid-body, and static or dynamic (such as rotary and oscillating) furnaces. Each design is engineered to solve a specific set of challenges in thermal processing.

Choosing the right tube furnace is not about finding the "best" model, but about matching the furnace's fundamental design—its physical access, sample orientation, and temperature profile control—to the precise requirements of your scientific or industrial process.

Core Design: Physical Access and Orientation

The most fundamental distinction in tube furnace design is how you access the work tube and how the furnace is oriented.

Split Tube Furnaces

These furnaces are built with a hinge mechanism, allowing the heating chamber to be opened into two halves. This design offers maximum convenience for loading and unloading process tubes, especially those with complex connections or flanges that cannot be fed through the end of a solid furnace. It also allows for rapid cooling of the sample.

Non-Split (Solid) Tube Furnaces

A non-split or solid furnace is a single, rigid cylinder. Samples and their process tubes must be inserted from one or both ends. This design typically offers superior temperature uniformity and stability because there are no seams or breaks in the heating chamber or insulation.

Horizontal vs. Vertical Orientation

Most furnace models, both split and non-split, can be configured for either horizontal or vertical use. Horizontal is the most common orientation for general-purpose heating. Vertical orientation is crucial for applications where gravity's effects are important, such as preventing powder segregation, promoting uniform melting, or certain crystal growth techniques.

Temperature Control: Zones and Uniformity

How a furnace controls temperature along the length of the process tube is critical for experimental success. This is managed by the number of independent heating zones.

Single-Zone Furnaces

This is the simplest configuration, featuring one set of heating elements managed by a single temperature controller. It is designed to create a single, centralized "hot zone" of uniform temperature. These are ideal for processing smaller samples or for applications where precise uniformity over a long length is not the primary concern.

Multi-Zone Furnaces

Multi-zone furnaces feature two, three, or sometimes up to five independently controlled heating zones arranged sequentially. The most common is the three-zone furnace, which uses two smaller "end zones" to compensate for heat loss at the ends of the tube. This allows for a much longer and more uniform central hot zone than is possible with a single-zone design.

Gradient Furnaces

A gradient furnace is a specific application of a multi-zone design. It is intentionally programmed to create a stable and controlled temperature difference from one end of the furnace to the other. This is essential for processes like chemical vapor transport or studying materials across a range of temperatures simultaneously.

Furnaces for Dynamic Processes

For applications involving powders, granules, or viscous liquids, ensuring every part of the sample is heated evenly requires movement.

Rotary Tube Furnaces

In a rotary furnace, the entire process tube is slowly rotated. This constant tumbling action is essential for applications like calcination, pyrolysis, and coating of powders, as it continuously exposes new surfaces to the heat source, ensuring homogeneity and process consistency. They can be designed for either batch or continuous processing.

Oscillating Tube Furnaces

Similar to a rotary furnace, this type introduces motion but does so by gently rocking or oscillating the tube back and forth. This provides a less aggressive mixing action, which can be ideal for more delicate materials or processes where tumbling is undesirable.

Understanding the Trade-offs

Every design choice involves a compromise. Recognizing these trade-offs is key to selecting the right instrument.

Access vs. Uniformity

The primary trade-off is between split and non-split designs. Split furnaces offer unparalleled access and convenience but may introduce minor temperature inconsistencies at the seams. Non-split furnaces provide the best possible thermal uniformity but can be more difficult to load and unload.

Simplicity vs. Control

A single-zone furnace is simple, cost-effective, and easy to operate. A multi-zone furnace provides far superior temperature uniformity and profiling capabilities but at the cost of increased complexity and expense.

Temperature Range as a Defining Factor

Across all these models, the maximum achievable temperature (ranging from 1100°C to 1800°C) is a critical specification. The required temperature dictates the type of heating elements and insulation used, which fundamentally impacts the furnace's cost and capabilities.

Making the Right Choice for Your Goal

Your specific application will determine which furnace configuration is most appropriate.

- If your primary focus is achieving the highest temperature uniformity for a static sample: A multi-zone, non-split furnace provides the most stable and homogenous heating environment.

- If your primary focus is rapid sample exchange or using complex reactors: A split-hinge furnace offers the necessary convenience and physical access.

- If your primary focus is uniformly heating loose powders or granules: A rotary tube furnace is the only design that ensures consistent mixing and thermal exposure.

- If your primary focus is creating a specific temperature profile along the sample: A multi-zone or dedicated gradient furnace is required for this level of control.

Understanding these core models transforms the selection process from a simple catalog review into a targeted engineering decision.

Summary Table:

| Feature | Key Models | Primary Application |

|---|---|---|

| Physical Access | Split (Hinge), Solid (Non-Split) | Easy loading vs. superior uniformity |

| Temperature Control | Single-Zone, Multi-Zone, Gradient | Simple heating vs. long uniform hot zones |

| Sample Motion | Static, Rotary, Oscillating | Static samples vs. powder/granule processing |

| Orientation | Horizontal, Vertical | General purpose vs. gravity-dependent processes |

Ready to find the ideal tube furnace for your specific application? The experts at KINTEK are here to help. We specialize in matching labs with the perfect equipment, from high-uniformity multi-zone furnaces for sensitive research to robust rotary furnaces for industrial processing. Let us guide you to a solution that ensures precision, efficiency, and reliability.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the basic construction and temperature control mechanism of a laboratory tube furnace? Master Precision Heating for Your Lab

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the catalysts used in biomass conversion? A Guide to Optimizing Your Process

- Which type of waste is removed by pyrolysis? Transforming Carbon-Based Waste into Valuable Resources

- What is the difference between a horizontal and vertical furnace? Choose the Right Orientation for Your Needs

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- What can you use glass tubes for? Essential Applications in Labs, Industry, and Design

- What are the typical heating zone configurations and maximum temperature capabilities of tube furnaces? Find the Right Setup for Your Lab