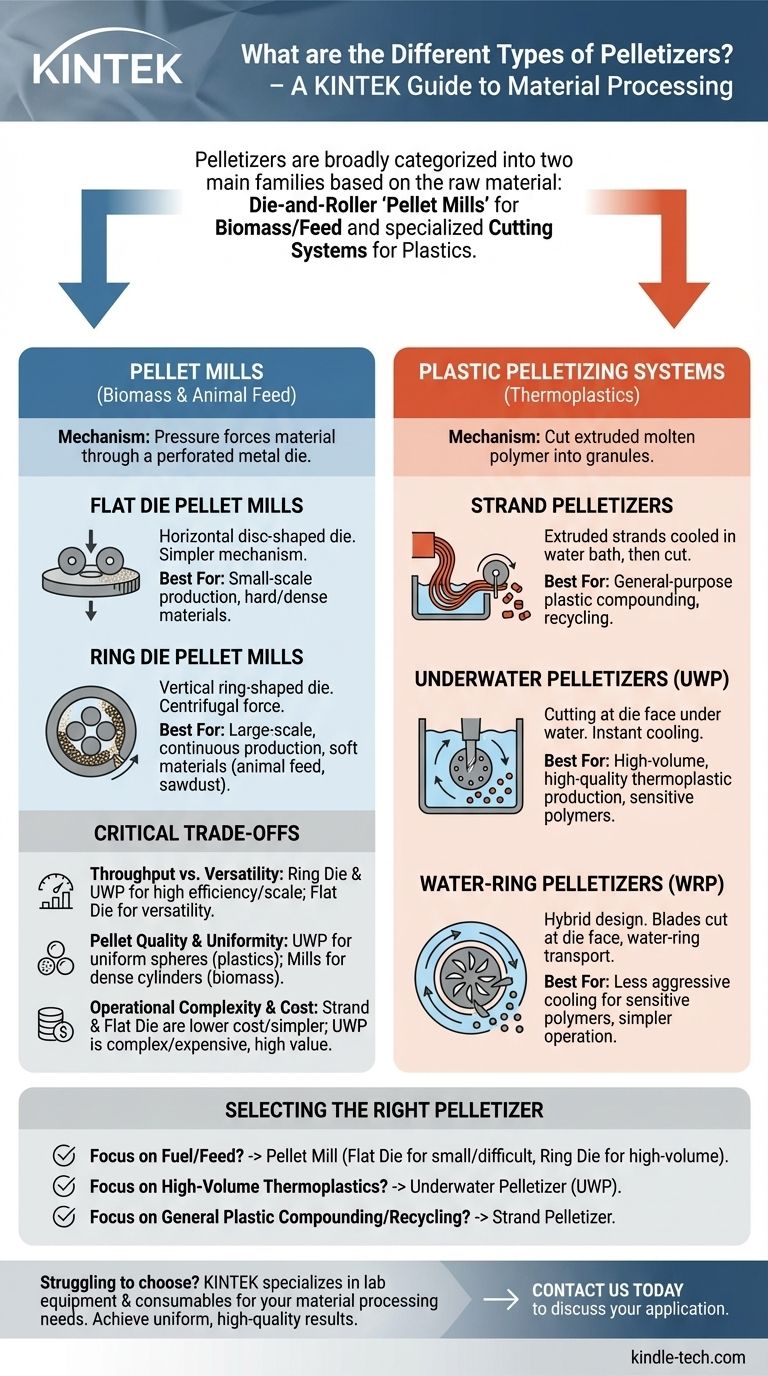

In industrial processing, pelletizers are broadly categorized into two main families: die-and-roller "pellet mills," typically used for biomass and animal feed, and specialized cutting systems used primarily for plastics. Pellet mills force material through a die using rollers, while plastic pelletizers typically cut extruded strands of molten polymer into small, uniform granules.

The fundamental choice in pelletizing technology is dictated by the raw material. The right machine depends entirely on whether you are densifying soft biomass or processing hard, molten thermoplastics.

The Two Dominant Pellet Mill Designs

The term pellet mill almost always refers to a machine that uses pressure to extrude material through a perforated metal die. The primary distinction comes down to the orientation of this die.

Flat Die Pellet Mills

A flat die pellet mill features a horizontal, disc-shaped die. Rollers are positioned on top of the die and rotate, forcing the raw material down through the holes.

This design is mechanically simpler and often favored for smaller-scale production or for processing very hard, dense materials that require immense pressure.

Ring Die Pellet Mills

A ring die pellet mill uses a vertical, ring-shaped die that rotates around a set of stationary rollers mounted inside it. Centrifugal force flings the material to the inner wall of the rotating die, where the rollers press it outward through the holes.

This configuration is highly efficient for continuous, large-scale production, particularly with softer materials like animal feed or sawdust, as it promotes a more consistent material flow.

Pelletizing Systems for Plastics

When processing polymers, the goal is not to densify loose material but to create uniform granules from a molten stream. These systems operate on a completely different principle than pellet mills.

Strand Pelletizers

This is the most common and straightforward method. Molten polymer is extruded through a die to form multiple continuous strands, like spaghetti.

These strands are then pulled through a water bath to cool and solidify before being fed into a cutter, which chops them into small, cylindrical pellets.

Underwater Pelletizers (UWP)

In a UWP system, the cutting action happens directly at the die face. As the molten polymer emerges from the die holes, a rotating cutting head immediately slices it into pellets.

This entire process occurs within a chamber of circulating water, which instantly cools and solidifies the pellets, typically forming them into uniform spheres. This method is ideal for high-volume production and for processing temperature-sensitive or sticky polymers.

Water-Ring Pelletizers (WRP)

A water-ring pelletizer is a hybrid design. Like a UWP, blades cut the molten polymer directly at the die face.

However, instead of being submerged, a ring of circulating water immediately catches the hot pellets and sweeps them away to a drying system. This method is less thermally aggressive than a UWP and simpler to operate.

Understanding the Critical Trade-offs

Choosing a pelletizer involves balancing cost, throughput, and the specific requirements of your material. No single system is universally superior.

Throughput vs. Material Versatility

High-throughput systems like ring die mills and underwater pelletizers are engineered for efficiency with specific material types. They excel in large-scale, continuous operations.

Conversely, flat die mills may have lower output but can often handle a wider variety of challenging or inconsistent feedstocks due to their direct, high-pressure mechanism.

Pellet Quality and Uniformity

For plastics, UWPs produce highly uniform, spherical pellets that offer excellent flowability and packing density, which is critical for subsequent processing steps like injection molding. Strand pellets are cylindrical and can have slight variations in length.

For biomass, both flat and ring die mills produce dense, cylindrical pellets. The key quality metric is durability—the pellet's ability to resist crumbling during transport.

Operational Complexity and Cost

Strand pelletizing lines and flat die mills represent a lower initial capital investment and are generally simpler to operate and maintain.

Underwater pelletizing systems are significantly more complex and expensive. They require precise control over water temperature, pressure, and flow, making them a choice for high-value, large-scale production where pellet quality is paramount.

Selecting the Right Pelletizer for Your Material

Your end goal and raw material are the only factors that matter when selecting a system.

- If your primary focus is producing fuel pellets or animal feed: A die-and-roller pellet mill is your technology. Choose a flat die for smaller-scale or difficult materials and a ring die for high-volume, continuous production.

- If your primary focus is compounding high volumes of thermoplastics: An underwater pelletizer (UWP) offers the best pellet quality and throughput for demanding applications.

- If your primary focus is general-purpose plastic compounding or recycling: A strand pelletizer provides a reliable, cost-effective, and versatile solution suitable for a wide range of polymers.

Ultimately, the right technology is the one that transforms your specific raw material into a uniform, valuable product with maximum efficiency.

Summary Table:

| Pelletizer Type | Primary Material | Key Mechanism | Best For |

|---|---|---|---|

| Flat Die Pellet Mill | Biomass, Animal Feed | Rollers press material through a horizontal die | Small-scale or difficult materials |

| Ring Die Pellet Mill | Biomass, Animal Feed | Rotating ring die forces material outward through holes | High-volume, continuous production |

| Strand Pelletizer | Plastics | Cuts cooled, extruded strands into pellets | General-purpose plastic compounding |

| Underwater Pelletizer (UWP) | Plastics | Cuts molten polymer at die face, underwater cooling | High-volume, high-quality thermoplastic production |

| Water-Ring Pelletizer (WRP) | Plastics | Cuts at die face, water-ring cooling and transport | Less aggressive cooling for sensitive polymers |

Struggling to choose the right pelletizer for your lab or production line? KINTEK specializes in lab equipment and consumables, providing expert solutions for your material processing needs. Whether you're densifying biomass for research or compounding polymers for development, our team can help you select the ideal pelletizing technology to achieve uniform, high-quality results. Contact us today to discuss your specific application and discover how KINTEK can enhance your efficiency and productivity!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- Why KBr is used as reference standard in FTIR? Unlock Clear, Accurate Solid Sample Analysis

- How do you prepare soil for XRF sample? A Step-by-Step Guide to Accurate Analysis