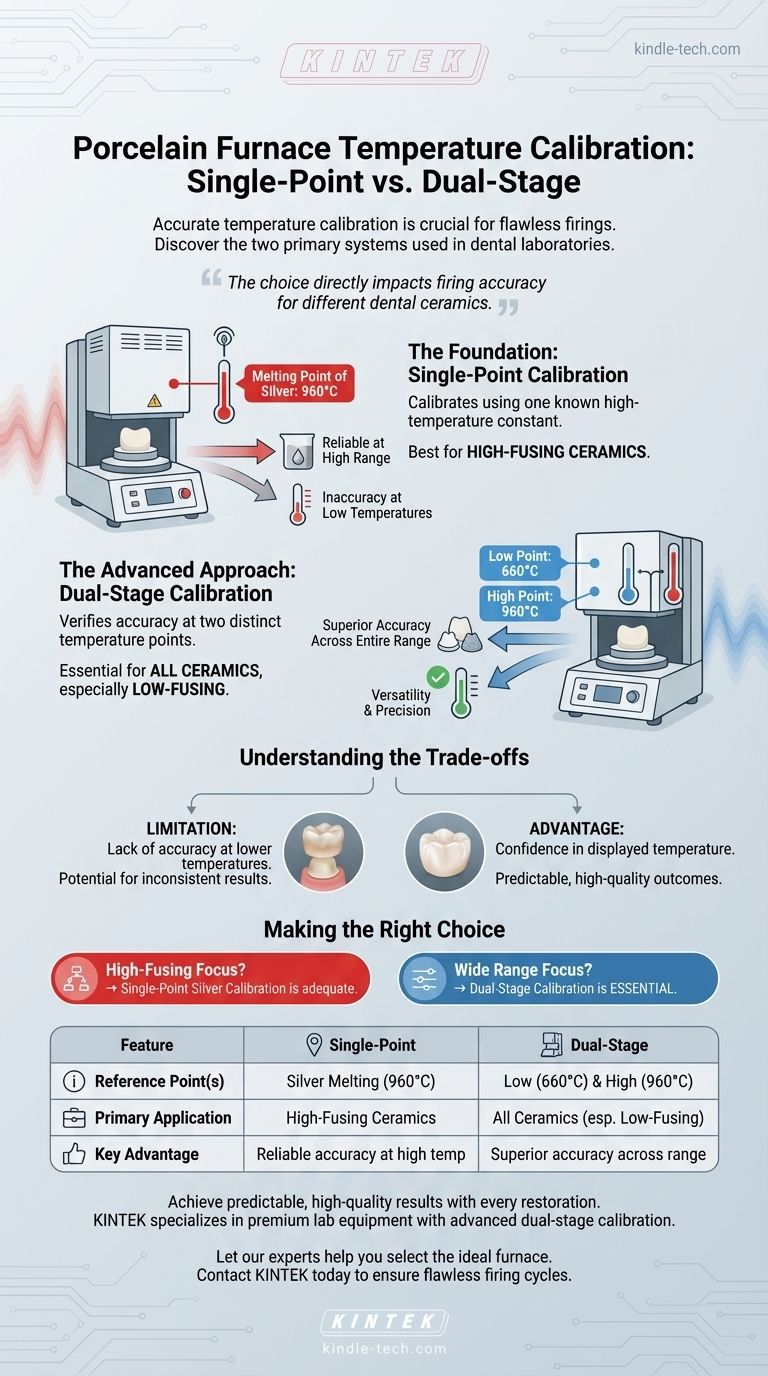

At their core, porcelain furnaces use two primary types of temperature calibration systems: single-point and dual-stage. The traditional method relies on a single high-temperature reference, typically the melting point of silver, while more advanced systems use two distinct temperature points to ensure accuracy across a much broader range.

The choice between a single-point and a dual-stage calibration system directly impacts the firing accuracy for different types of dental ceramics. While single-point is adequate for high-fusing materials, dual-stage calibration is critical for achieving predictable results with modern low-fusing ceramics.

The Foundation: Single-Point Calibration

How It Works

A single-point system calibrates the furnace's temperature sensor against one known physical constant. The most common reference used in the industry is the precise melting point of silver (960°C).

The furnace is programmed to recognize this exact temperature, ensuring it is accurate at that specific high point.

The Primary Application

This method is generally effective for high-fusing ceramics. Since these materials fire at temperatures close to the silver reference point, the furnace's calibration remains reliable and accurate within that narrow, high-temperature range.

The Advanced Approach: Dual-Stage Calibration

Addressing the Accuracy Gap

Relying on a single high-temperature point can lead to significant inaccuracies when firing materials at much lower temperatures. Dual-stage calibration was developed to solve this exact problem.

The Two-Point Method

This system uses a patented method to verify accuracy at two distinct temperatures: one low and one high. For example, it might use reference points at both 660°C and 960°C.

Why It's More Reliable

By calibrating at both ends of the spectrum, a dual-stage system creates a far more accurate temperature profile across the entire operational range of the furnace. This ensures precision whether you are working with low-fusing or high-fusing materials.

Understanding the Trade-offs

The Limitation of Single-Point Systems

The primary weakness of single-point calibration is its lack of accuracy at lower temperatures. As the furnace operates further away from its single calibration point (960°C), its potential for temperature deviation increases.

This can lead to inconsistent, under-fired, or over-fired results, especially with the growing use of advanced low-fusing ceramics.

The Advantage of Dual-Stage Systems

The clear advantage of a dual-stage system is its versatility and precision. It provides confidence that the temperature displayed is the true temperature inside the muffle, regardless of the ceramic being used.

This reliability is essential for labs that handle a diverse range of restorative materials and demand predictable, high-quality outcomes every time.

Making the Right Choice for Your Goal

The correct calibration system is the one that matches the materials you use most often.

- If your primary focus is high-fusing ceramics: A single-point silver calibration system is generally adequate and reliable for your needs.

- If your primary focus is a wide range of materials, including low-fusing ceramics: A dual-stage calibration system is essential for achieving consistent accuracy and predictable clinical results.

Ultimately, choosing a furnace with the right calibration technology ensures the quality, aesthetics, and longevity of your final restorations.

Summary Table:

| Calibration Type | Key Reference Point(s) | Primary Application | Key Advantage |

|---|---|---|---|

| Single-Point | Silver Melting Point (960°C) | High-Fusing Ceramics | Reliable accuracy at high temperatures |

| Dual-Stage | Low Point (e.g., 660°C) & High Point (960°C) | All Ceramics, especially Low-Fusing | Superior accuracy across the entire temperature range |

Achieve predictable, high-quality results with every restoration. The right porcelain furnace calibration is critical for the accuracy and longevity of your dental ceramics. KINTEK specializes in premium lab equipment, including advanced furnaces with dual-stage calibration for ultimate precision.

Let our experts help you select the ideal furnace for your specific ceramic needs. Contact KINTEK today to discuss your laboratory's requirements and ensure flawless firing cycles.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What is the critical point of heat treatment? Master the Key to Steel Transformation

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating

- What is the effect of temperature on calcination? Master Precise Heat Control for Material Properties

- What are the advantages and limitations of heat treatment? Tailor Material Properties for Peak Performance

- At what temperature does quartz soften? Understand the practical limits for lab equipment