Technically, fused quartz begins to soften at approximately 1630°C (2966°F). However, this number represents a standardized material property and is not a safe operating temperature. For practical applications, especially over extended periods, the effective limit is much lower, often around 1200°C to 1270°C.

The most critical takeaway is that quartz does not have a sharp, defined melting point like ice. It softens gradually over a wide temperature range, and its safe, usable temperature is significantly lower than its technical softening point, depending heavily on the duration of heat exposure.

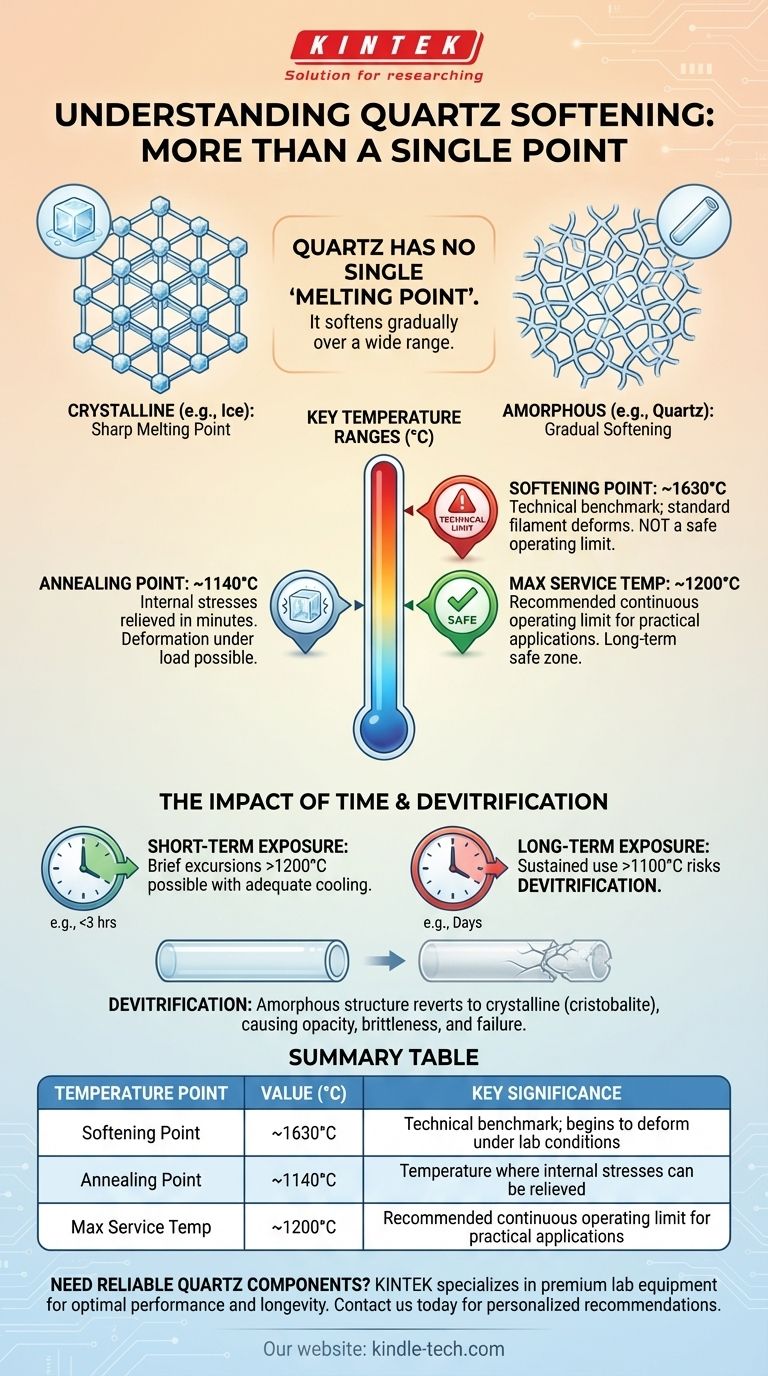

Why Quartz Has No Single "Melting Point"

To use quartz effectively in high-temperature environments, you must first understand its fundamental nature. It is not a crystalline solid but an amorphous one, which dictates its behavior under heat.

The Amorphous Structure of Glass

Unlike a crystal, which has an orderly, repeating atomic lattice, fused quartz is a glass. Its silicon and oxygen atoms are arranged in a disordered, random network.

This lack of a uniform structure means there is no single temperature at which all the atomic bonds break simultaneously.

A Gradual Transition

Instead of melting, quartz undergoes a gradual transition. As temperature increases, it moves from a rigid solid to a viscous, plastic-like material over a wide range. This is why we talk about a "softening point" rather than a "melting point."

Defining the Key Temperature Ranges

The apparent contradiction in softening temperatures found in technical literature arises from the difference between a material's intrinsic property and its practical service limit.

The Softening Point (~1630°C)

This is a formally defined technical value. It's the temperature at which a standard filament of the glass begins to deform under its own weight under specific laboratory conditions. It is a benchmark for the material itself, not a guideline for application design.

The Annealing Point (~1140°C)

Well below the softening point is the annealing point. This is the temperature at which internal stresses within the quartz can be relieved in a matter of minutes. Heating above this point can cause deformation if the component is under any load.

The Maximum Service Temperature (~1200°C)

This is the most important figure for practical use. Most manufacturers recommend a maximum continuous operating temperature of around 1100°C to 1200°C. Pushing past this, even for a few hours, risks permanent damage.

Understanding the Trade-offs: The Impact of Time

The primary variable that determines the failure of a quartz component at high temperature is time. The relationship between temperature and time is not linear.

Short-Term vs. Long-Term Exposure

Quartz can withstand brief excursions to temperatures above its recommended service limit. However, sustained use even slightly above 1200°C will cause problems.

For example, a quartz tube might survive at 1200°C for a few hours but would fail if held there continuously for days.

The Risk of Devitrification

When held at high temperatures for extended periods (e.g., above 1100°C), fused quartz can begin to devitrify. The amorphous structure starts to revert to its crystalline form (cristobalite).

This process makes the quartz opaque, brittle, and far more susceptible to thermal shock and breakage upon cooling. This is the most common mode of failure for quartz in high-temperature applications.

Making the Right Choice for Your Application

Selecting the right operating temperature requires balancing performance needs with component longevity. Use these guidelines to make an informed decision.

- If your primary focus is maximum component life and reliability: Operate your quartz components below 1100°C for any continuous process.

- If your primary focus is a short, high-temperature process: You can approach the 1200°C service limit, but only for brief periods (e.g., under 3 hours) and allow for adequate cooling cycles.

- If you are designing equipment: Never use the 1630°C softening point for any calculation. Base all safety and operational limits on the much lower maximum service temperature.

Ultimately, your success depends on respecting the material's practical limits, not just its theoretical properties.

Summary Table:

| Temperature Point | Value (°C) | Key Significance |

|---|---|---|

| Softening Point | ~1630°C | Technical benchmark where quartz begins to deform under lab conditions |

| Annealing Point | ~1140°C | Temperature where internal stresses can be relieved in minutes |

| Max Service Temp | ~1200°C | Recommended continuous operating limit for practical applications |

Need reliable quartz components for your high-temperature applications? KINTEK specializes in premium lab equipment and consumables, including quartzware designed for optimal performance and longevity. Our experts can help you select the right materials for your specific temperature requirements, ensuring safety and efficiency in your laboratory processes. Contact us today to discuss your quartz application needs and get personalized recommendations from our technical team!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of using a 0.45μm microporous filter membrane? Ensure Accurate Mine Wastewater Analysis

- How does the performance of single-stage and two-stage rotary vane pumps compare? Optimize Your Vacuum Efficiency

- What are the uses of desiccators and specific thermal regulators? Expert Insights for Vapor-Assisted Conversion

- Why are zirconia grinding balls preferred for HE-O-MIEC mixing? Ensure Purity & Precision in Synthesis

- What is the function of a magnetic stirring hot plate in zirconia-alumina synthesis? Master Solution Combustion Prep

- Why are cemented carbide balls selected as the grinding media? Optimize Graphene-Reinforced Alumina Ceramics

- What are the technical advantages of using zirconia (ZrO2) grinding balls? Enhancing Silicon Composite Anode Performance

- Why are high-purity alumina (Al2O3) hangers necessary for high-temperature oxidation kinetics testing of Fe-16Cr alloys?